Marker disk adjustments, Marker disk angle, Marker disk angle axis – Great Plains PD8070 Operator Manual User Manual

Page 45: Marker folding speed, Marker disk angle marker disk angle axis

Great Plains Manufacturing, Inc.

Adjustments

41

2014-07-23

401-479M

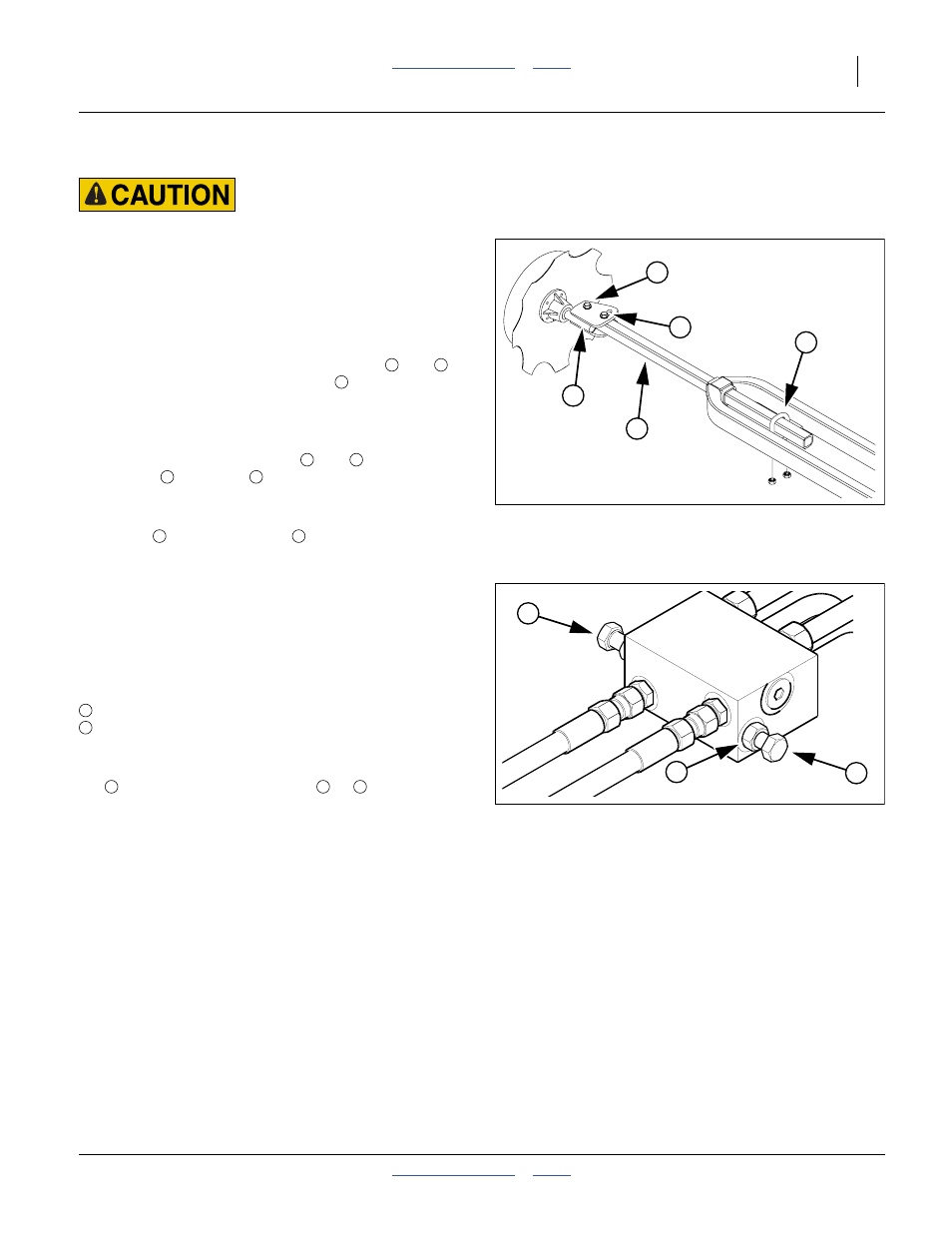

Marker Disk Adjustments

Sharp Object Hazard:

Use caution when making adjustments in this area.

Marker disks may be sharp.

The mark left by the marker disk may be changed by

several methods.

Refer to Figure 38

Marker Disk Angle

1.

To change the angle of cut, loosen bolts

and

,

rotate disk assembly around bolt

and retighten

bolts.

Marker Disk Angle Axis

2.

The disk may be mounted to throw dirt in or out. To

reverse throw, remove bolts

and

, remove

spindle

from tube

and remount it with the

spindle axis behind the tube.

3.

If vertical angle adjustment is needed, loosen the

U-bolt

, remove the tube

, rotate it 90 degrees,

and re-secure it.

Marker Folding Speed

The marker hydraulic system is equipped with needle

valves to control how fast each marker operates. The

needle valves are built into the sequence valve body,

which is located directly below the slow-moving-vehicle

placard. There are two hex adjustment heads, one for

controlling:

marker speed up (folding) and

marker speed down (unfolding).

Excessive folding speeds can cause marker damage.

With the tractor engine at an operating rpm, loosen jam

nut

and adjust the needle valve

or

to limit the

marker to a safe operating speed.

Make sure all adjustments are made with warm oil. Fold

the marker up and down a few times and recheck for

pinching and kinking of hoses.

Figure 38

Marker Angle Adjustments

25450

6

5

4

7

8

4

5

5

4

5

7

8

6

8

Figure 39

Marker Rate Valve

15029

2

1

3

1

2

3

1

2