Seed rate, Transmission adjustment, Contact wheel 2-to-1 drive reduction – Great Plains PD8070 Operator Manual User Manual

Page 35: Seed rate transmission adjustment

Great Plains Manufacturing, Inc.

Adjustments

31

2014-07-23

401-479M

Seed Rate

There are separate charts for brush and finger pickup

meters. If you are unfamiliar with the charts, see

“Reading the Brush Meter Chart” on page 33 or

“Reading the Finger Meter Chart” on page 35.

To change meters, see “Meter Maintenance” on

page 72.

For brush meters, the chart has separate columns based

on the cell count of the seed plate installed. For plate

selection see “Seed Plates” on page 94. To change

plates, see “Installing Brush Meter Plates” on page 19.

With the meters set up, the rate is adjusted by sprocket

pairing at the planter transmission.

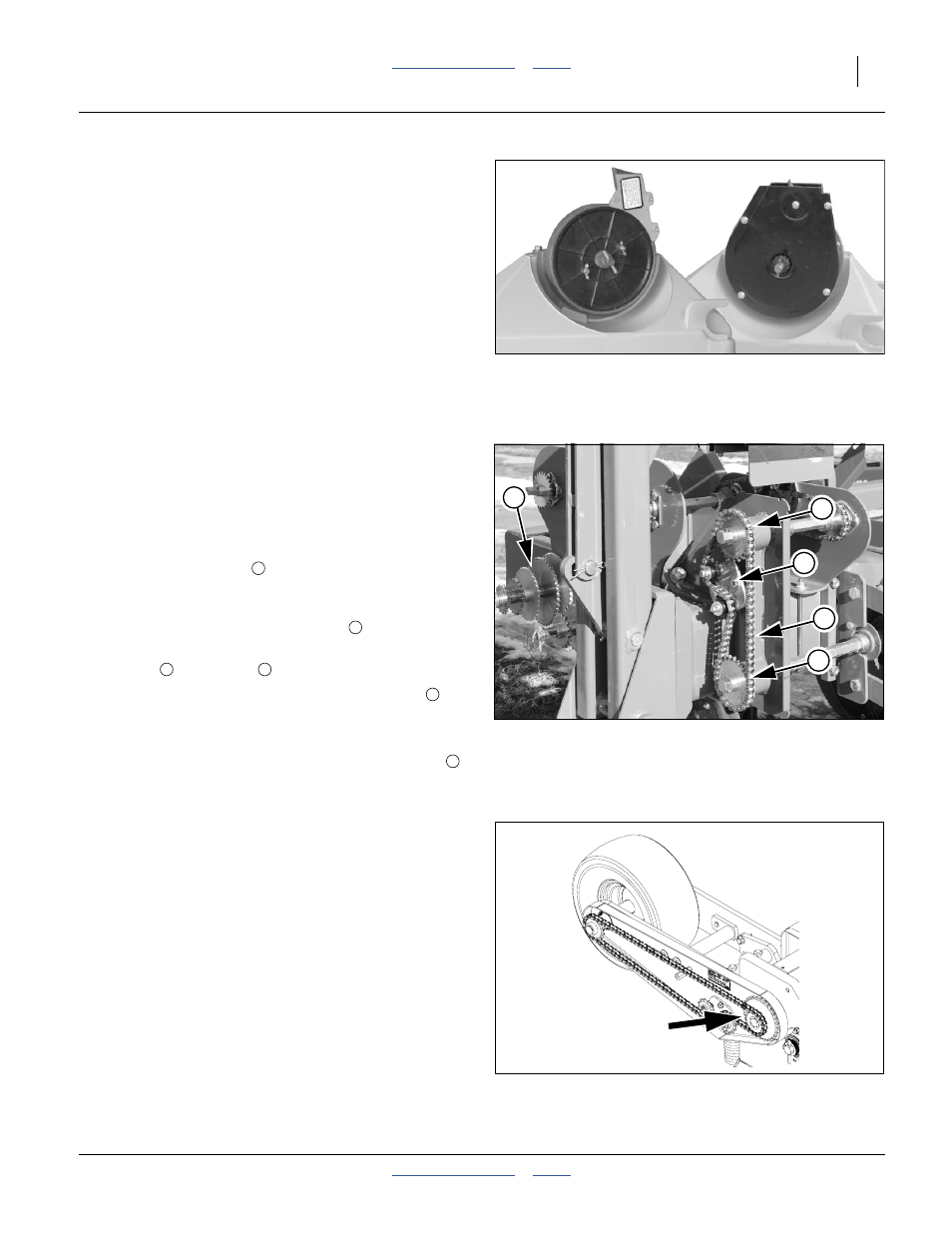

Transmission Adjustment

To change planting population, change sprocket

combination on transmission.

1.

See “Brush Meter Rate Chart” on page 34 or

“Finger Meter Rate Chart” on page 36 for proper

sprocket combination for desired population.

Loosen carriage bolt

and flange nut on idler plate.

Rotate idler plate and move idlers out of chain.

Remove chain.

3.

Select new sprockets from storage

.

4.

Place correct sprockets for desired planting rate on

Driving

and Driven

shafts.

5.

Store all unused sprockets on storage bracket

.

6.

Reroute chain over idlers and sprockets.

7.

Turn idler plate counterclockwise to engage chain.

Leave 6 mm (

1

⁄

4

inch) slack in longest chain span

.

Retighten carriage bolt and flange nut on idler plate.

Contact Wheel 2-to-1 Drive Reduction

The charts “Brush Meter Rate Chart” on page 34 and

“Finger Meter Rate Chart” on page 36 are based on a

15-tooth, driven sprocket in the contact-wheel drive. To

reduce planting rates by one-half, switch to 28-tooth

sprocket.

Figure 30

Brush and Finger Pickup Meters

28133

Figure 31

Planter Transmission

25449

3

4

2

1

5

1

2

3

4

2

5

Figure 32

2-to-1 Drive Reduction

16863