Installing brush meter plates – Great Plains PD8070 Operator Manual User Manual

Page 23

Great Plains Manufacturing, Inc.

Preparation and Setup

19

2014-07-23

401-479M

Installing Brush Meter Plates

A selection of seed plates are available for the brush

meter (see “Seed Plates” on page 94). Use a seed plate

specific to the crop, seed variety, and seed rate range.

If the seed plates (or meters) need to be changed,

perform this operation before loading seed.

1.

Select 8 of the next seed plates to install. Check that

they are all for the correct seed, seed variety and cell

count. To aid in identification, there is a table of plate

characteristics on page 94.

2.

If seed is already loaded, see “Material Clean-Out”

on page 63.

3.

If changing from finger pickup to brush meter, see

“Meter Maintenance” on page 72.

Refer to Figure 15

4.

Uncouple the meter drive (page 26), release the

hopper latch (page 63), and remove each hopper

from its row unit.

5.

Remove the two wing nuts

that secure the seed

plate to the meter shaft.

Treated Seed Hazard:

Follow material supplier recommendations carefully. Handle

the meter and plate as if they were treated seed. Use

supplier-recommended cleaning agents.Any seed treatment

build-up inside a meter is likely to be at a higher concentration

than on the actual seed.

Refer to Figure 16

6.

Pull the plate off the threaded studs, and angle one

side of the center hole over one end of the roll pin

in the drive shaft.

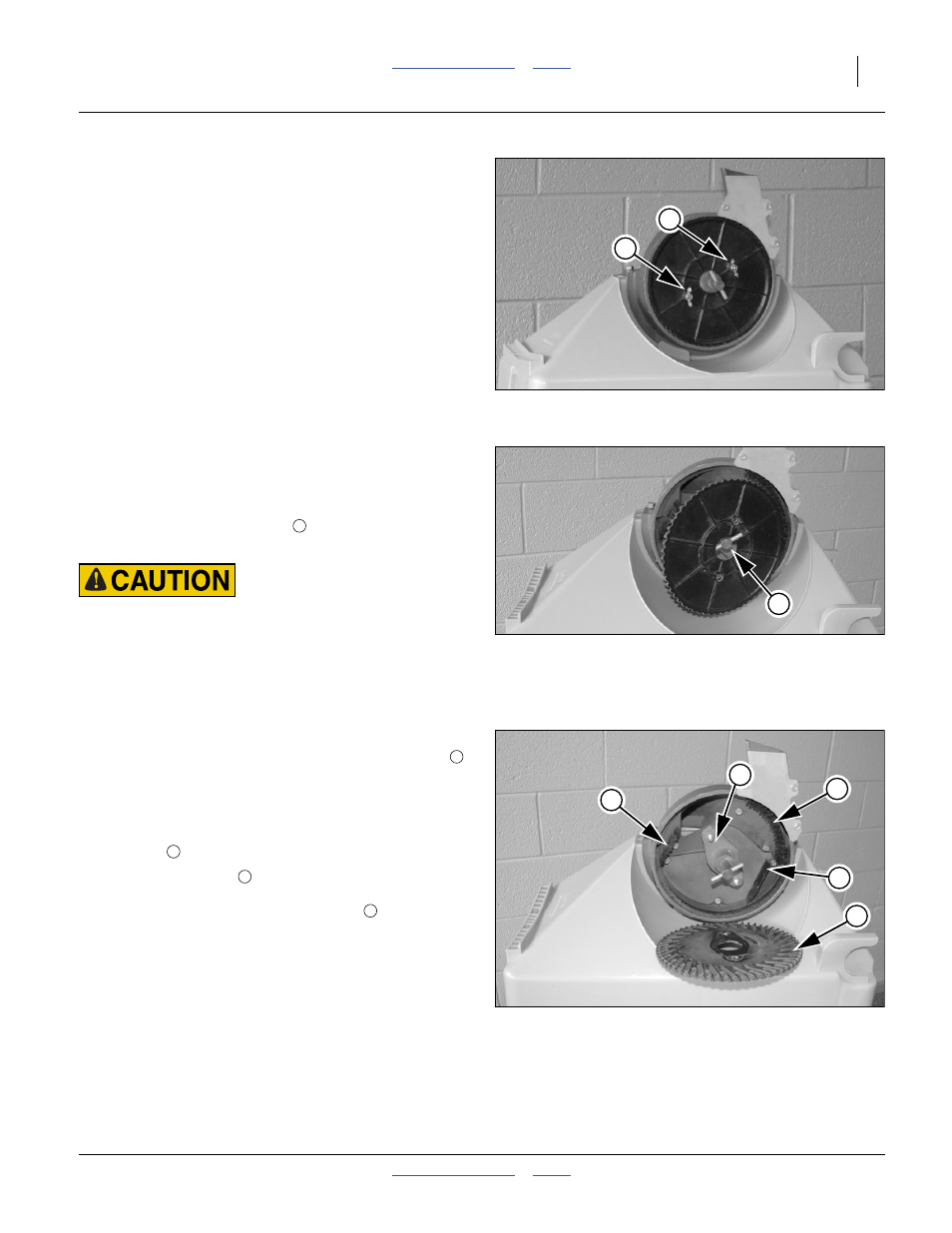

Refer to Figure 17

7.

With the seed plate removed, clean any debris from

inside the meter, and inspect the condition of the

brushes

8.

Select a new plate

. Inspect the cells for any

damage, and make sure the inside surface is clean,

so that it will seat full on the disc hub

.

9.

Orient the plate with the cell side (not the spoke side)

toward the meter shaft. Reversing the removal

process above, angle the hole over end of the drive

shaft roll pin, then the other end, and seat the plate

on the threaded studs. Secure with wing nuts.

10. Spin the plate by hand, counter-clockwise, to verify

that it sits flush and does not wobble.

11. Re-mount the hopper on the row unit and secure

with latch.

Figure 15

Brush Meter Plate Wing Nuts

28126

1

1

Figure 16

Brush Meter Plate Removal

28127

2

1

Figure 17

Brush Meter Inspection

28128

3

3

3

5

4

2

3

3

4