10 connecting torch supply leads – Tweco 6000GST Merlin Plasma Cutting CE Slave Power Supply User Manual

Page 26

INSTALLATION PROCEDURES

3-8

Manual 0-2653

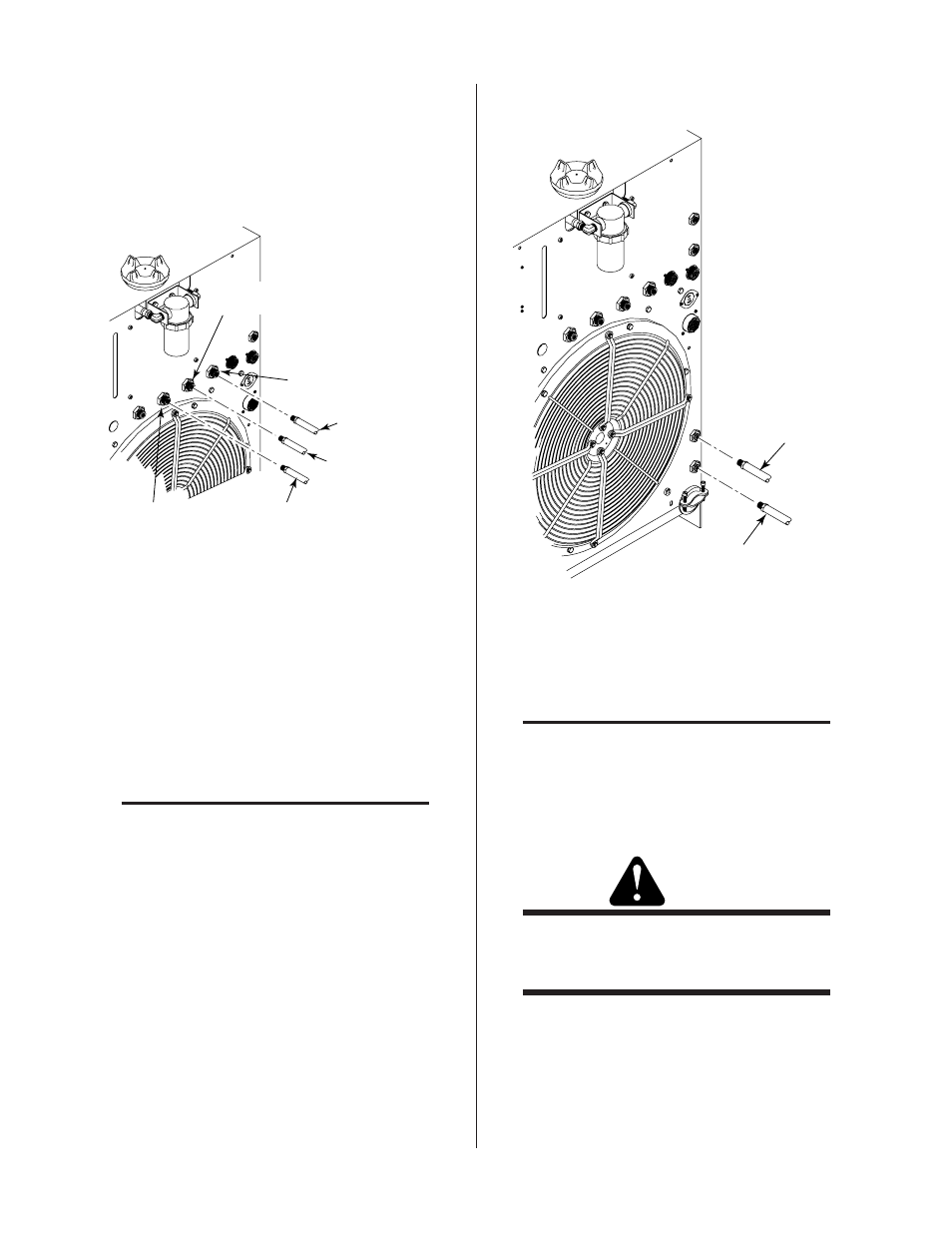

Connect the gas supply to the Power Supply as follows:

1. Connect the black supply hose(s) from the plasma gas

regulator(s) directly to the input fitting on the rear panel

of the Power Supply marked PLASMA AIR, O2 (oxy-

gen), N2 (nitrogen), and Ar/H2 (argon/hydrogen).

Plasma N2 Gas

Supply Hose

A-01762

PLASMA Ar/H2

Gas Fitting

PLASMA O

2

Gas Fitting

Plasma O

2

Gas

Supply Hose

Plasma Ar/H2 Gas

Supply Hose

PLASMA N2

Gas Fitting

Figure 3-8 Plasma Gas Connections

2. Connect the yellow supply hose(s) from the second-

ary gas regulator(s) directly to the input fitting on the

rear panel of the Power Supply marked SECONDARY

AIR, SECONDARY OTHER, and SECONDARY N2 &

PRE FLOW N2 (nitrogen).

When oxygen (O

2

) is used as the plasma gas then nitro-

gen (N2) is required at the secondary for pre-flow gas

even if another gas is used for secondary gas.

NOTE

A typical 50 lb. CO

2

cylinder can deliver a con-

tinuous flow rate of 35 scfh (16.5 lpm). To obtain

the required flow rate for the torch, it may be nec-

essary to manifold several CO

2

cylinders. Con-

tinuous flow requirements will depend on the spe-

cific application and duty cycle.

SECONDARY OTHER

Gas Supply

SECONDARY N2

& PRE FLOW N2

Gas Supply

A-01763

Figure 3-9 Secondary Gas Connections

C. Using Water Secondary

NOTES

Tap water should only be used as a secondary gas

on machine torches.

The tap water source does not need to be deionized,

but in water systems with extremely high mineral

content a water softener is recommended.

WARNING

The Optional Water Mist Secondary Flow Con-

trol Assembly must be installed when using water

as the secondary.

Tap water can be used instead of a secondary gas and is con-

nected to the Power Supply as follows:

1. The tap water source must be capable of delivering a mini-

mum water pressure of 50 psi (3.5 bar) and flow of 9 gph (40

lph).