Tweco 6000GST Merlin Plasma Cutting CE Slave Power Supply User Manual

Page 23

Manual 0-2653

3-5

INSTALLATION PROCEDURES

2. Grounding for components mounted on the cutting table

(CNC controllers, height controllers, plasma remote con-

trols, etc.) should follow the manufacturer’s recommenda-

tions for wire size, type, and connection point locations.

For Thermal Dynamics components it is recommended to

use a minimum of 10 AWG (6.00 mm

2

European) wire or flat

copper braid with cross section equal to or greater than 10

AWG connected to the cutting table frame. The connec-

tion point must be clean bare metal; rust and paint make

poor connections. For all components, wires larger than

the recommended minimum can be used and may improve

noise protection.

3. The cutting machine frame is then connected to the “Star”

point using 1/0 AWG (50.0 mm

2

European) or larger wire.

4. The plasma power supply work cable (see NOTE) is con-

nected to the cutting table at the single point “Star” ground.

NOTE

Do Not connect the work cable directly to the

ground rod.

5. Make sure work cable and ground cables are prop-

erly connected. The work cable must have a solid

connection to the cutting table. The work and ground

connections must be free from rust, dirt, grease, oil and

paint. If necessary grind or sand down to bare metal. Use

lock washers to keep the connections tight. Using electri-

cal joint compound to prevent corrosion is also recom-

mended.

6. The plasma power supply chassis is connected to the

power distribution system ground as required by elec-

trical codes. If the plasma supply is close to the cut-

ting table (see NOTE) a second ground rod is not usu-

ally needed, in fact it could be detrimental as it can

set up ground loop currents that cause interference.

When the plasma power supply is far away from the

ground rod and interference is experienced, it may

help to install a second earth ground rod next to the

plasma power supply. The plasma power supply

chassis would then be connected to this ground rod.

NOTE

It is recommended that the Plasma Power Supply

be within 20 - 30 ft (6.1 – 9.1 m) of the cutting

table, if possible.

7. The plasma control cable should be shielded with the

shield connected only at the cutting machine end.

Connecting the shield at both ends will allow ground

loop currents which may cause more interference than

with no shield at all.

C. Creating An Earth Ground

1. To create a solid, low resistance, earth ground, drive a

1/2 in (12 mm) or greater diameter copper clad ground

rod at least 6 - 8 ft (1.8 - 2.4 m) into the earth so that

the rod contacts moist soil over most of its length.

Depending on location, a greater depth may be re-

quired to obtain a low resistance ground (see NOTE).

Ground rods, typically 10 ft (3.0 m) long, may be

welded end to end for greater lengths. Locate the rod

as close as possible to the work table. Install a ground

wire, 1/0 AWG (50.0 mm

2

European) or greater, be-

tween the ground rod and the star ground point on

the cutting table.

NOTE

Ideally, a properly installed ground rod will have a

resistance of three ohms or less.

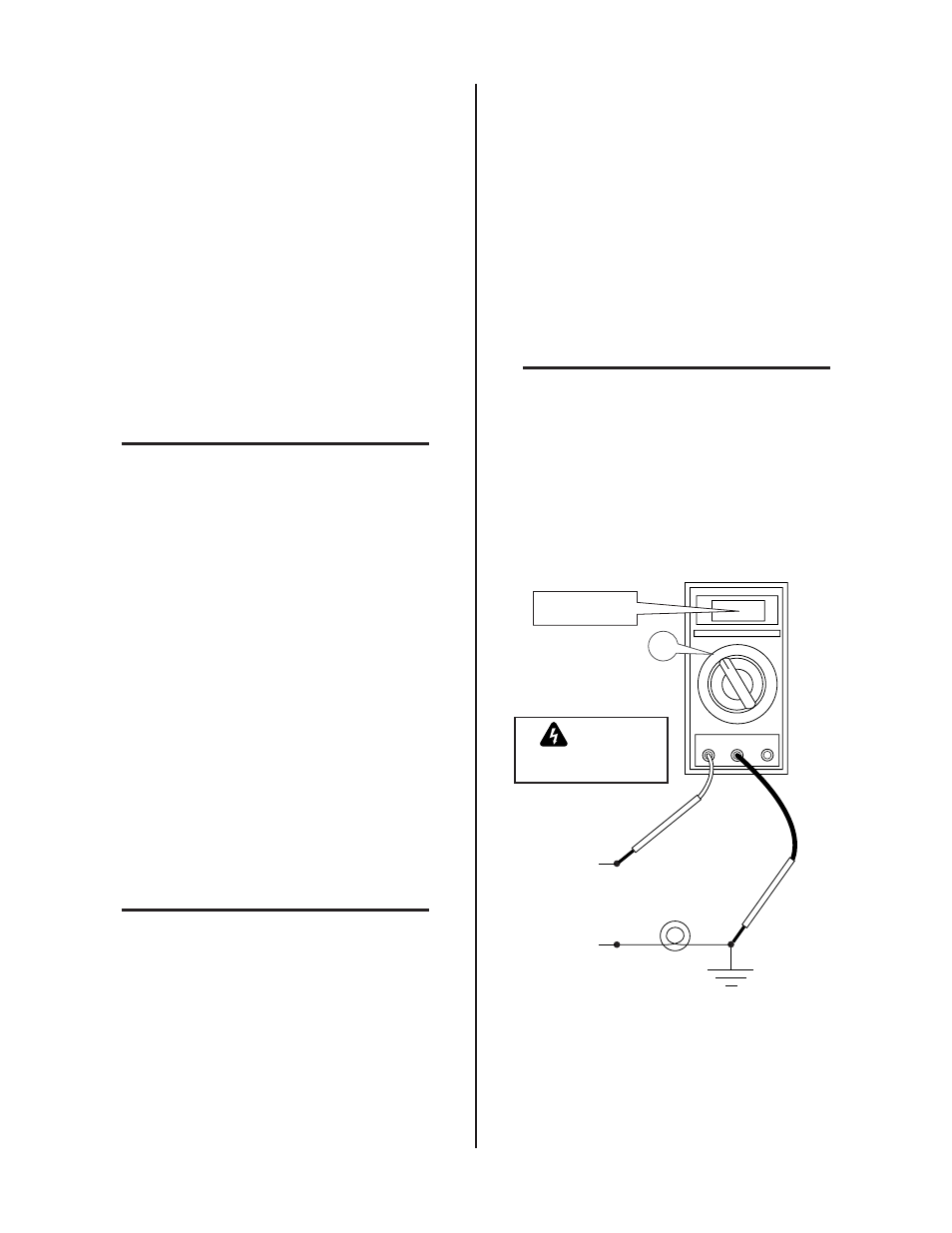

To test for a proper earth ground, refer to the follow-

ing diagram. Ideally, the reading on the multimeter

should be as follows:

• For 115VAC: 3.0 VAC

• For 230VAC: 1.5 VAC

A-02971

+

_

Meter set to

VAC setting

Machine

Earth Ground

Neutral

Line (Hot)

100W

Light Bulb

115 or 230VAC

WARNING

Use extreme caution. This

test uses live voltage.

115VAC: 3.0 VAC

230VAC: 1.5 VAC

V

~

V

~

VR COM A

Ground Testing