tekmar 406 House Control Installation User Manual

Page 40

©

2012 406_D

-

11/12

40

of

48

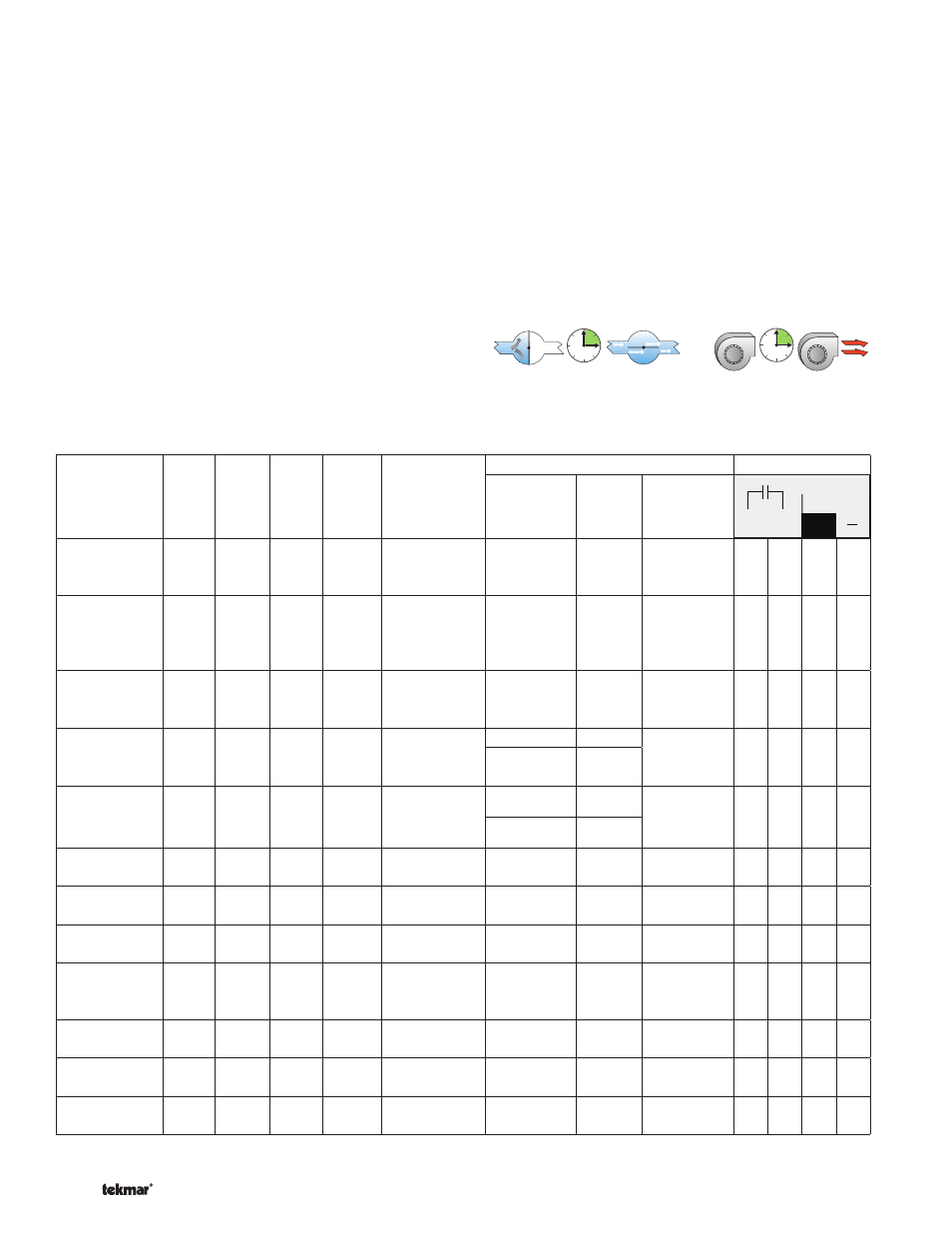

Boiler Model

BOIL

TYPE

BOIL

MOTR

(sec)

MIN

MOD

(%)

MOD

DELAY

(min)

Required

Equipment

from Boiler

Manufacturer

Boiler Control Setting

Wiring Terminals

+

Mod dc/mA

Backup

Parameter Setting Reference

Buderus

GB142, 162,

312

0-10

10

30

0:10

EM10 Module

None

None

None

2

1

Burnham

Alpine

4-20

30

0

0:10

None

Central

Heating

Modulation

Source

4-20mA

p.109 I&O

Manual

1

2

9

10

Dunkirk

Q95M-200

0-10

10

18

1:45

HAM 0-

10VDC

Module

Parameter

34 [P .34]

[- - 04]

p.3 Ham

Installation

Instructions

+

-

Heat Transfer

Products Elite

0-10

24

16

0:00

None

Function 16 0-10 Volt

p.57

Installation

Manual

+

_

Function 17

Fan

Speed

Heat Transfer

Products

Munchkin

0-10

60

16

0:00

Munchkin

Interface

Board

Function 16

1

p.60 Boiler

Manual

Pu

rp

le

Ye

llo

w

Function 17

1

Laars

NeoTherm

4-20

30

0

0:50

None

None

None

None

5

6

4

3

Lochinvar

Knight

0-10

16

20

0:10

None

H3

Active

p.24 Service

Manual

33

34

Lochinvar

Sync

0-10

16

20

0:10

None

Demand

conf

3

p.19 Service

Manual

19

20

Peerless

PureFire

REV2

0-10

50

20

0:00

Interface

Adapter PFA-

1

Heating

Mode

Mode 5

p.43 I&O

Manual

16

15

Triangle Tube

Prestige Solo

0-10

90

18

2:05

None

Parameter

45

02

p.54 I&M

Manual

17+ 18-

Weil-McLain

Ultra Series 3

0-10

60

20

0:30

None

ADD’L HEAT

DEMAND

Type 4

p.64 Boiler

Manual

6

5

Viessmann

Vitodens 100

EMS 2

N/A

N/A

N/A

Input Module

0-10V OT

None

None

None

1

4

For updated information or wiring details, check the service bulletin page on www.tekmarControls.com.

Essential Settings for House Control 406 with Common Modulating Boilers

--------------------------------

--------------------------------

Modulating Boiler Operation --------------------

--------------------

The 406 can operate a single hot-water modulating boiler

using the Mod dc/mA output and the Backup contact. Not all

boilers require the use of the Backup contact.

The control operates the boiler by first switching the Backup

contact to allow the modulating boiler to go through the ignition

sequence. A 0-10 V (dc) or 4-20 mA analog signal is then used

to modulate the boiler firing rate starting from 50% (5 V (dc)

or 12 mA signal) for 30 seconds.

After the 30 second delay has elapsed, the control will then

allow the boiler to modulate down to the minimum modulation

setting and hold it there for the MOD DELAY time.

After the MOD DELAY has elapsed, the control uses PID

logic to change the boiler firing rate signal in order to satisfy

the boiler target temperature. When the firing rate signal is

reduced down to the MIN MOD setting and the boiler supply

temperature exceeds the boiler target by 1/2 of the differential,

the control will shut off the burner.

Boiler Motor Speed ------------------------------

------------------------------

The Motor Speed is the amount of time the boiler requires to

go from 0% modulation to 100% modulation.

Gas valve actuating motors have a design time from fully

closed to fully opened which can be found in the manufacturer’s

manual. The Motor Speed should be set to this time.

The Motor Speed setting for a Variable Frequency Drive (VFD)

is the amount of time required to go from a stopped position

to 100% fan speed. Since a VFD has a very quick response

rate, it may be necessary to increase the Motor Speed setting

in order to increase the stability of the boiler modulation.

Use the BOIL MOTR setting in the Adjust Menu to select an

appropriate boiler motor speed.

OR