tekmar 374 Universal Reset Control User Manual

Page 9

9 of 36

© 2009 D 374 - 03/09

Increasing Load

Time

Differential

On

Off

Te

m

pe

ratu

re f

all

Te

m

pe

ra

tu

re

ri

se

Time

Desired temperature

160°F (71°C)

Differential

10°F (6°C)

Boiler Off

Boiler On

155°F (68°C)

165°F (74°C)

Boiler

Sensor

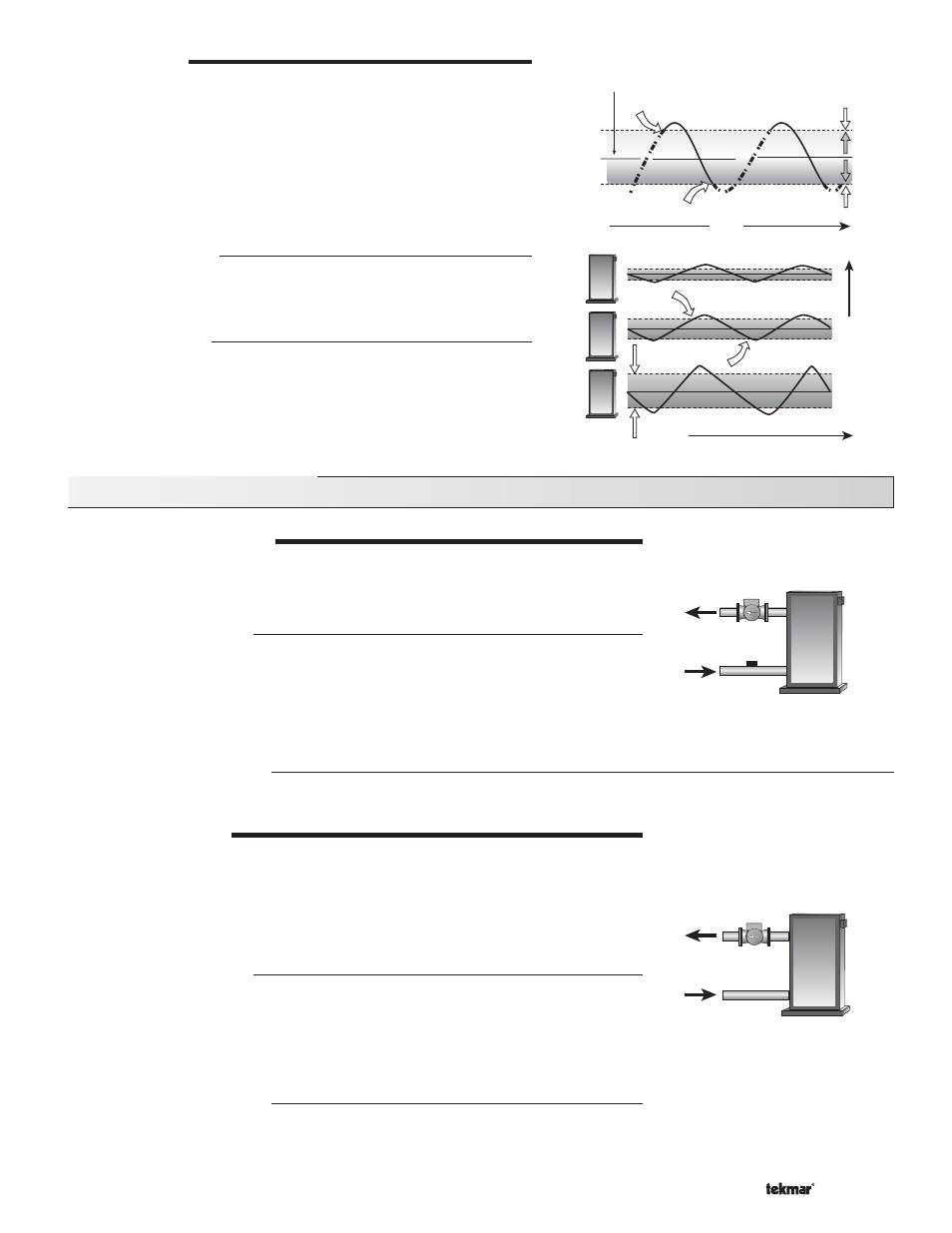

DIFFERENTIAL

An on / off heat source must be operated with a differential in order

to prevent short cycling. With the control, either a fixed or an auto

differential may be selected. The boiler differential is divided around the

boiler target temperature. The stage contact closes when the supply

water temperature is ½ of the differential setting below the boiler target

temperature. Additional staging occurs if the first stage is unable to raise

the supply water temperature up to the boiler target temperature at a

reasonable rate. As the supply temperature reaches ½ of the differential

above the boiler target temperature, stages are staged off.

Fixed Differential

If the user desires to have a fixed differential, this is set using the

boiler differential (BOIL DIFF) setting in the ADJUST menu.

Auto Differential

If the Auto Differential is selected, the control automatically determines

the best differential as the load changes. This reduces potential short

cycling during light load conditions.

BOILER RETURN SENSOR

The boiler sensor should be located on the boiler return if the 374 is one of many controls

that can call for boiler operation or the boiler has its own control with outdoor reset and

setpoint operation. The boiler return sensor provides boiler return protection.

Boiler Enable Contact

When the

Return / Supply DIP switch is set to Return, the 374 provides a boiler enable when

there is a requirement for heat. The 374 no longer tries to control the boiler supply water

temperature directly but allows the boiler to operate at its operating aquastat setting. The

boiler enable contact is closed at either 30% or 10% operation of the mixing device, which is

set using the

30% Enable / 10% Enable DIP switch. The boiler enable contact remains closed

until the mixing device(s) no longer requires heat.

Section B2: Boiler Enable

Setpoint Enable Contact

If a DHW demand or a Setpoint demand is registered, the Setpoint Enable contact is closed to provide a setpoint demand to the boiler’s

control if a setpoint input is available. When a return sensor is being used, the boiler should operate its own boiler pump.

NO BOILER SENSOR

The 374 is capable of operating without a boiler sensor if desired. In this case, there is no

boiler protection provided by the 374.

To operate the 374 without a boiler sensor, the

Return / Supply DIP switch is set to Return

and the control must be powered up without the boiler sensor connected. This type of

application is typical if the 374 is drawing heat from a heat source that already incorporates

some form of boiler return protection.

Boiler Enable Contact

When the

Return / Supply DIP switch is set to Return, the 374 provides a boiler enable

when there is a requirement for heat. The 374 no longer tries to control the boiler supply

water temperature directly but allows the boiler to operate at its operating aquastat setting.

The boiler enable contact is closed at either 30% or 10% operation of the mixing device,

which is set using the

30% Enable / 10% Enable DIP switch. The boiler enable contact

remains closed until the mixing device(s) no longer requires heat.

Setpoint Enable Contact

If a DHW demand or a Setpoint demand is registered, the Setpoint Enable contact is closed to provide a setpoint demand to

the boiler’s control if a setpoint input is available.