tekmar 374 Universal Reset Control User Manual

Page 8

©

2009 D

374

-

03/09

8

of

36

Boiler Mass

The boiler mass setting allows the installer to adjust the control to the thermal mass of the type of heat sources used in the

application. If the heating system is causing the boiler(s) to be staged on and off in rapid succession, a higher boiler mass

setting will result in a decrease in the amount of cycling. Conversely, if the system is slow to respond to heat requirements, then

decreasing the boiler mass setting will increase the response rate by staging the boilers at a faster rate.

Lo (1)

The Lo setting is selected if the boiler(s) that is used has a low thermal mass. This means that the boiler(s) has a very small

water content and has very little metal in the heat exchanger. A boiler that has a low thermal mass comes up to temperature

quite rapidly when fired. This is typical of many copper fin-tube boilers. The Lo mass setting provides a fast staging rate of

on / off boiler stages.

Med (2)

The Med setting is selected if the boiler(s) that is used has a medium thermal mass. This means that the boiler(s) either has

a large water content and a low metal content or a small water content and a high metal content. This is typical of many

modern residential cast iron boilers or steel tube boilers. The Med mass setting provides a moderate staging rate of on / off

boiler stages.

Hi (3)

The Hi setting is selected if the boiler(s) that is used has a high thermal mass. This means that the boiler(s) has both a large water

content and a large metal content. A boiler that has a high thermal mass is relatively slow in coming up to temperature. This is typical

of many commercial cast iron and steel tube boilers. The Hi mass setting provides a slow staging rate of on / off boiler stages.

Time

Boiler #2 Fires

Boiler #1 Fires

Stage Delay

Boiler Contact Closes

Fire

Delay

Fire

Delay

Boiler #1

Boiler #2

1

2

720 hours

672 hours

2

1

672 hours

720 hours

STAGING

The control operates up to two on / off boiler stages (or one low / high fire) in order to provide the required supply temperature. After

a stage is turned on in the firing sequence, the control waits for a minimum time delay. The minimum time delay is adjustable using

the Stage Delay setting. After the Stage Delay has expired, the control examines the control error to determine when the next stage

is to fire. The control error is determined using Proportional, Integral and Derivative (PID) logic.

Proportional – compares the actual supply temperature to the boiler target temperature. The colder the supply water temperature,

the sooner the next stage is turned on.

Integral – compares the actual supply temperature to the boiler target temperature over a period of time.

Derivative – compares how fast or slow the supply water temperature is changing. If the supply temperature is increasing slowly,

the next stage is turned on sooner. If the supply temperature is increasing quickly, the next stage is turned on later, if at all.

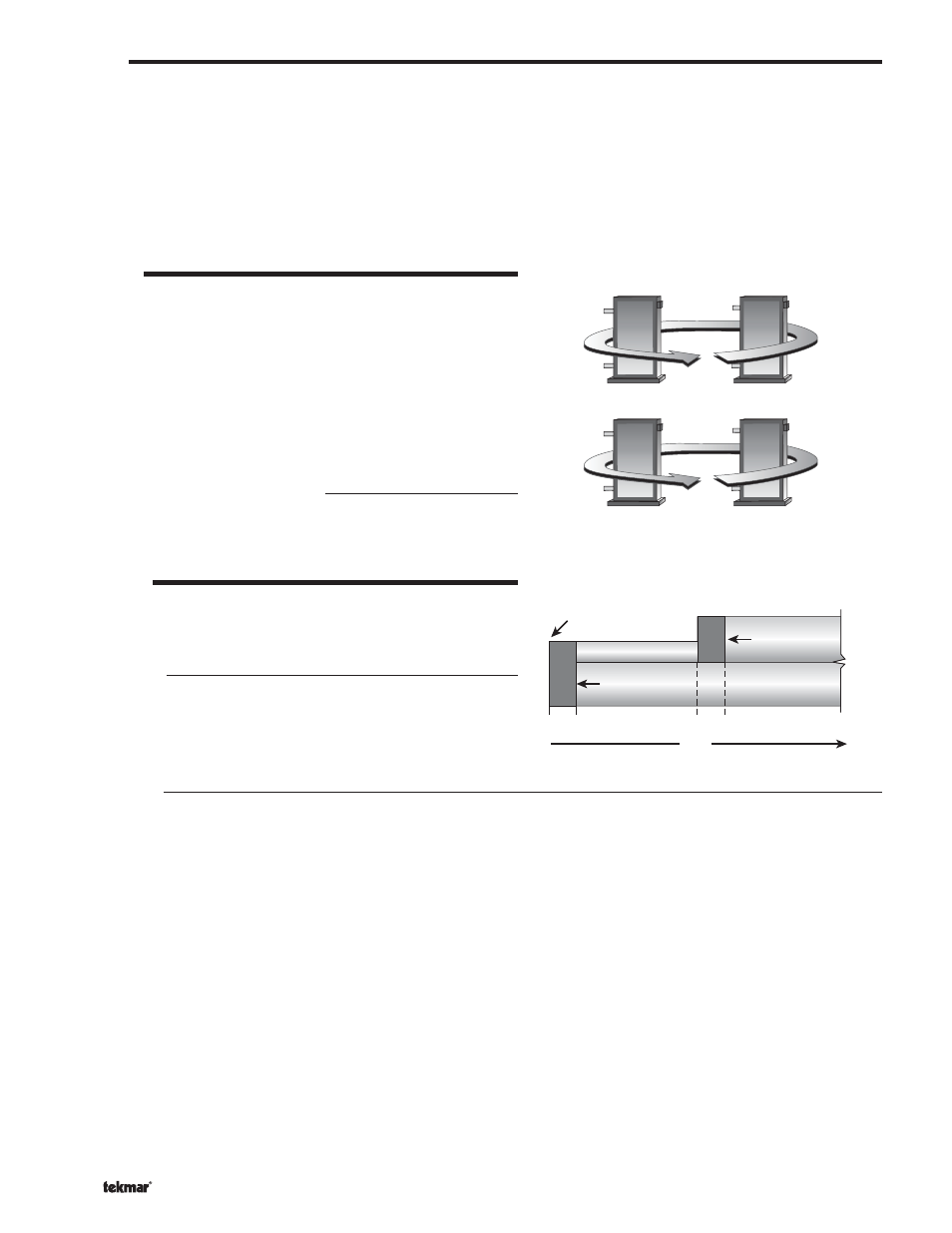

ROTATION

The control’s Equal Run Time Rotation function is fixed at 48 hours. The

firing order of the boilers changes whenever one boiler accumulates 48

hours more running time than the other boiler. After each rotation, the

boiler with the least running hours is the first to fire and the boiler with

the most running hours is the last to fire. This function ensures that both

boilers receive equal amounts of use. When the

Rotate / Off DIP switch

is set to the

Off position, the firing sequence always begins with boiler

one and then boiler two.

Note: When using a single two-stage boiler, ensure that the

Rotate / Off

DIP switch is set to Off.

Resetting the Rotation Sequence

To reset the rotation sequence, set the

Rotate / Off DIP switch to

the

Off setting for 5 seconds and then return the DIP switch to the

Rotate setting.

FIRE DELAY

The Fire Delay is the time delay that occurs between the time that the

control closes a stage contact to fire a stage and the burner fires for

that stage.

Stage Delay

The stage delay is the minimum time delay between the firing of stages.

After this delay has expired the control can fire the next stage if it is

required. This setting can be adjusted manually or set to an automatic

setting. When the automatic setting is used, the control determines

the best stage delay based on the operation of the system.