tekmar 374 Universal Reset Control User Manual

Page 15

15 of 36

© 2009 D 374 - 03/09

MIXING TERMINAL UNITS

When a terminal unit is selected, the control automatically loads the mixing design temperature, mixing maximum supply temperature,

and mixing minimum supply temperature. The factory defaults are listed below. The factory defaults can be changed to better

match the installed system. If a factory default has been changed, refer to section A to reload the factory defaults.

Terminal Unit

High Mass

Radiant (1)

Low Mass

Radiant (2)

Fancoil

(3)

Fin-Tube

Convector (4)

Radiator

(5)

Baseboard

(6)

MIX DSGN

120°F (49°C)

140°F (60°C)

190°F (88°C)

180°F (82°C)

160°F (71°C)

150°F (66°C)

MIX MAX

140°F (60°C)

160°F (71°C)

210°F (99°C)

200°F (93°C)

180°F (82°C)

170°F (77°C)

MIX MIN

OFF

OFF

100°F (38°C)

OFF

OFF

OFF

MIX MODE 2 – MIXING SETPOINT OPERATION

Mixing device 2 can operate at a mixing setpoint temperature by setting Mix 2 Mode to 2. The Mix 2 Target temperature can then

be set to the desired temperature. While the boiler supply temperature is close to the boiler minimum temperature, the mix 1 device

has priority over the mix 2 device when set to Mix 2 Mode 2.

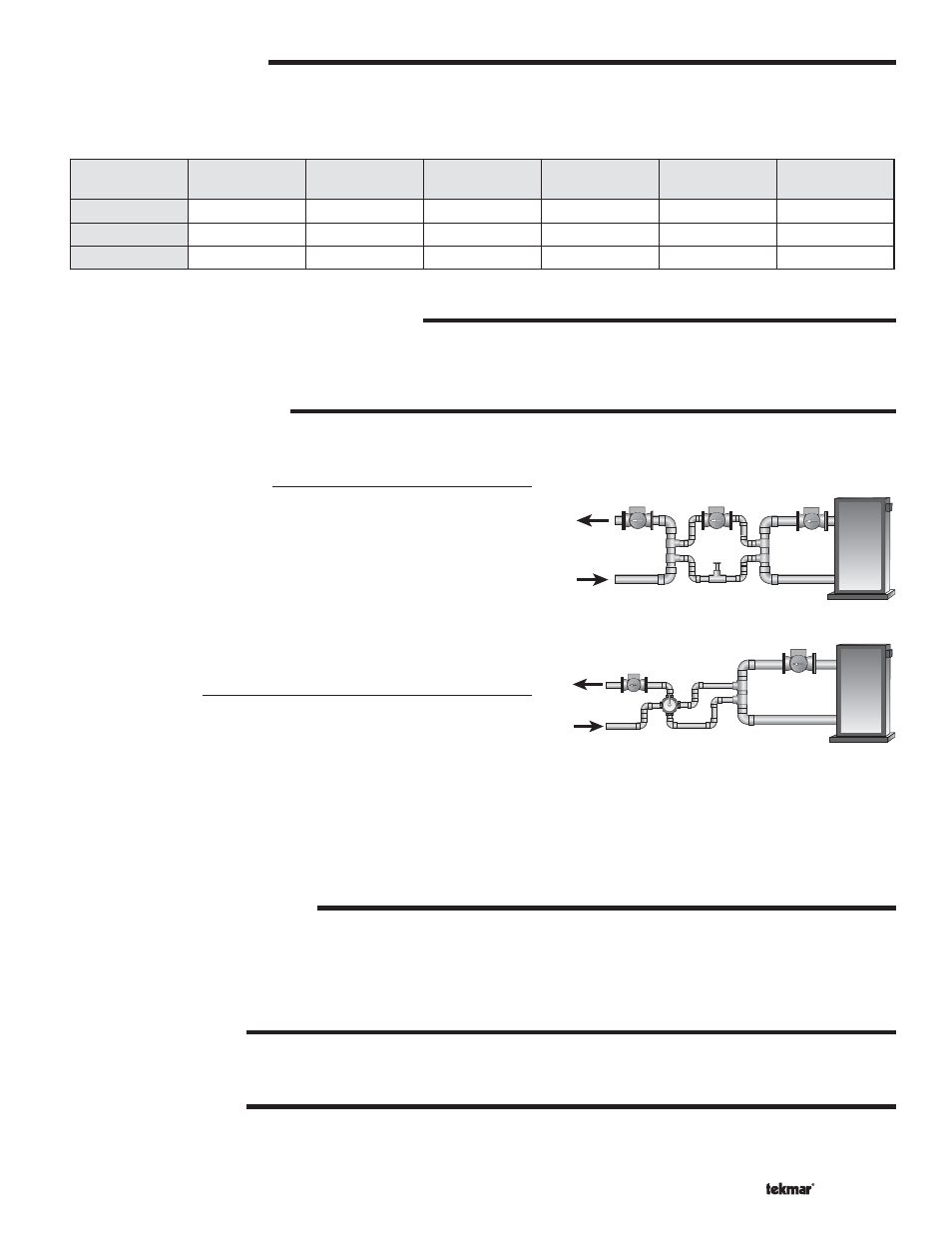

MIXING DEVICE SELECTION

The control can supply a lower water temperature to part of the heating system by varying the speed of an injection pump or

modulating a mixing valve. This selection is made using the

Floating / Variable DIP switch.

Variable Speed Injection

Standard wet rotor circulators are connected to the control on

Var1 terminal (2) for mix 1 demands and Var2 terminal (5) for mix 2

demands. The control increases or decreases the power output to

the circulator when there is mix demand. The circulator speed varies

to maintain the correct mixed supply water temperature at the mix

supply sensor. For correct sizing and piping of the variable speed

injection driven circulator, refer to essay E 021. A visual indication of

the current variable speed output is displayed in the LCD in the form of

a segmented bar graph. There are separate bar graphs for each mix 1

and mix 2 outputs as indicated by a 1 or a 2 next to the bar graph.

Floating Action

Floating action actuator motors are connected to the control on the

Opn

and

Cls terminals. Mix 1 has Opn and Cls terminals (1 and 2) and Mix 2

has separate

Opn and Cls terminals (4 and 5). Power for both floating

action actuator motors are shared on the

Pwr Mix terminal (3).

The control pulses the actuator motor open or close to maintain the correct supply water temperature at the mix supply sensor

when there is a mix demand. The mixing valve that the actuator is connected to can be either a 2-way, 3-way or 4-way valve. A

visual indication as to whether the control is currently opening or closing the mixing valve is displayed in the LCD with the words

Open and Close while viewing the Mix Supply and Mix Target temperatures. Also, a visual indication of the current position of

the valve is displayed in the LCD in the form of a segmented bar graph. There are separate bar graphs for each mix 1 and mix 2

outputs as indicated by a 1 or a 2 next to the bar graph.

BOILER MINIMUM PROTECTION

The control is capable of providing boiler protection from cold mixing system return water temperatures. If the boiler water temperature

is cooler than the Boiler Minimum setting while the boiler is firing, the control reduces the output from the mixing devices. If mix2

is operating in setpoint mode 2, it is the first to reduce its output. Otherwise, both outputs are reduced at the same rate. Reducing

the mixing output limits the amount of cool return water to the boiler and allows the boiler water temperature to recover. This feature

can only be used if the boiler sensor is on the supply or on the return.

MIX 1 PUMP CONTACT

If the control receives a

Mix 1 Demand and is not in WWSD, the control closes the Mix1 P2 pump contact and the mixing pump 2

segment is displayed in the LCD.

MIX 2 PUMP CONTACT

If the control receives a

Mix 2 Demand and is not in WWSD, the control closes the Mix2 P3 pump contact and the mixing pump 3

segment is displayed in the LCD.