Sequence of operation, General operation, Pg 4 – tekmar 262 Boiler Control Installation User Manual

Page 4

4 of 36

Copyright © D 262 -

12/08

Section A —General Operation

POWERING UP THE CONTROL

When the Boiler Control 262 is powered up, the control displays the control type number in the LCD for 2 seconds. Next, the software

version is displayed for 2 seconds. Finally, the control enters into the normal operating mode and the LCD defaults to displaying the

current outdoor air temperature.

MODES OF OPERATION (MODE)

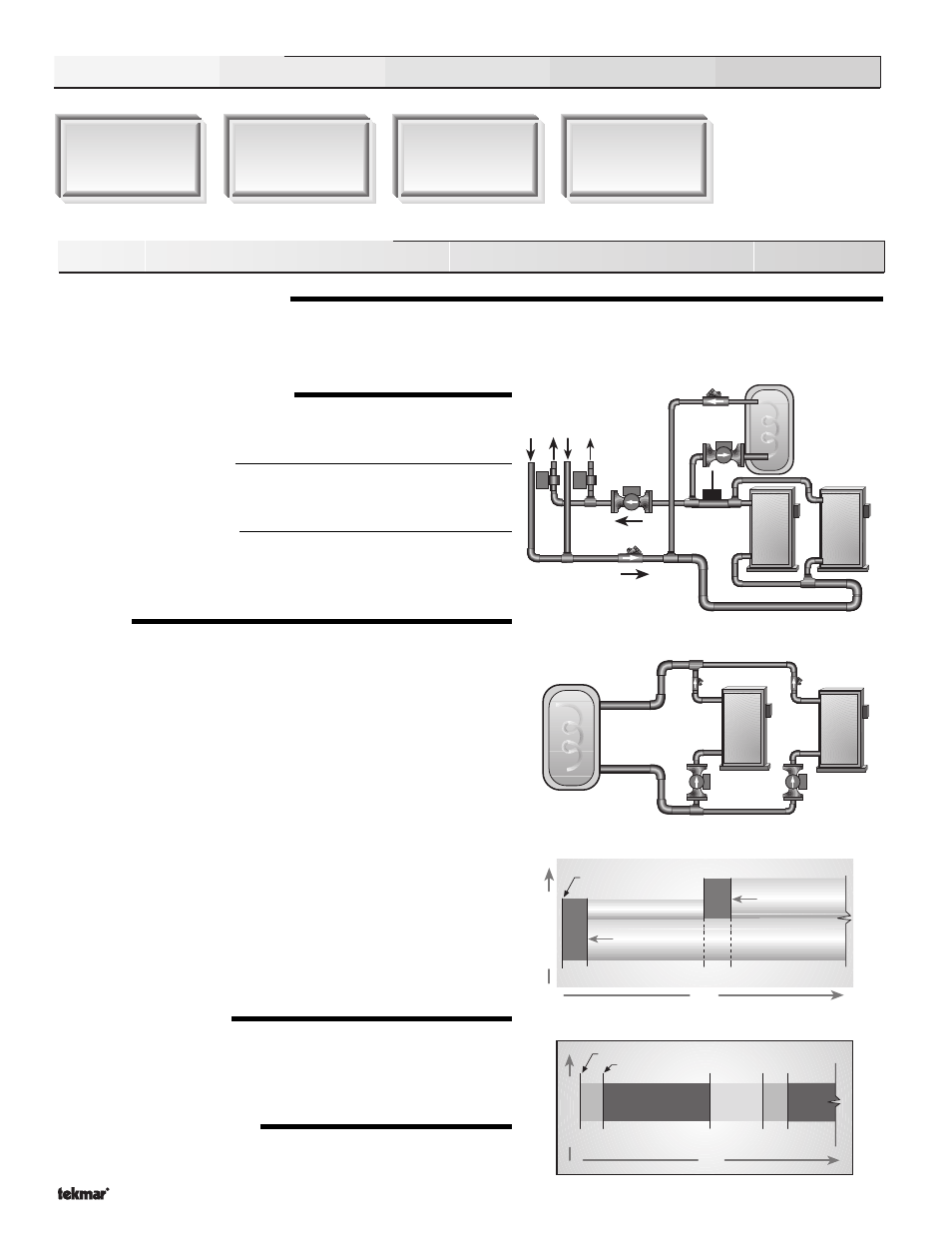

The Boiler Control 262 has two operating modes. The mode of operation

for which the control is to operate is selected in the

Adjust Menu.

Mode 1 (MODE = —1—)

Mode 1 is designed for one or two stages of Heating, Domestic Hot

Water (DHW), and Setpoint operation.

Mode 2 (MODE = —2—)

Mode 2 is designed for dedicated DHW operation. In this mode, the 262

controls one or two stages of heat for DHW generation (see Section C3

Dedicated DHW).

STAGING

The 262 controls up to two stages in order to supply the required target

temperature. After each stage is turned on in the firing sequence, the

control waits a minimum amount of time before turning on the next stage.

The minimum time between stages is the total of the fire delay (FIRE DLY)

setting plus the minimum inter-stage delay selected by the boiler mass

(Boil MASS) setting. After the minimum time delay between stages has

expired, the 262 examines the control error to determine when the next

stage is to fire. The control error is determined using Proportional, Integral,

and Derivative (PID) logic.

Proportional - compares the actual supply temperature to the boiler target

(Boil TRG) temperature. The colder the supply water temperature, the

sooner the next stage is turned on.

Integral - compares the actual supply temperature to the Boil TRG

temperature over a period of time.

Derivative - determines how fast or slow the supply water temperature is

changing. If the supply temperature is increasing slowly, the next stage is

turned on sooner. If the supply temperature is increasing quickly, the next

stage is turned on later, if at all.

Each stage has a minimum on time and a minimum off time.

FIRE DELAY (FIRE DLY)

The Fire Delay is the delay time that may occur between the time that the

262 closes a stage contact and the burner fires for that stage. This delay

is usually the result of burner pre-purge or other forms of time delay built

into the burner’s safety circuits.

BOILER MASS (Boil MASS)

The Boiler Mass setting allows the installer to adjust the control to the

thermal mass of different types of heat sources used.

Sequence of Operation

Section A

General Operation

Page 4 - 6

Section B

Boiler Reset

Page 6 - 10

Section C

Domestic Hot

Water (DHW)

Page 10 - 12

Section D

Setpoint

Page 12

Boiler T

emperature

Time

Boiler #1

Boiler #2

Fire

Delay

Fire

Delay

Interstage Delay

Boiler #1 Fires

Boiler #2 Fires

Boiler Contact Closes

Boiler T

emperature

Time

Fire

Delay

Fire

Delay

Boiler Contact Closes

Boiler Fires

Minimum

Off Time

Minimum On Time

Minim

Boiler

Sensor

P

DHW

Pump

Boiler

Pump