tekmar 262 Boiler Control Installation User Manual

Page 12

12 of 36

Copyright © D 262 -

12/08

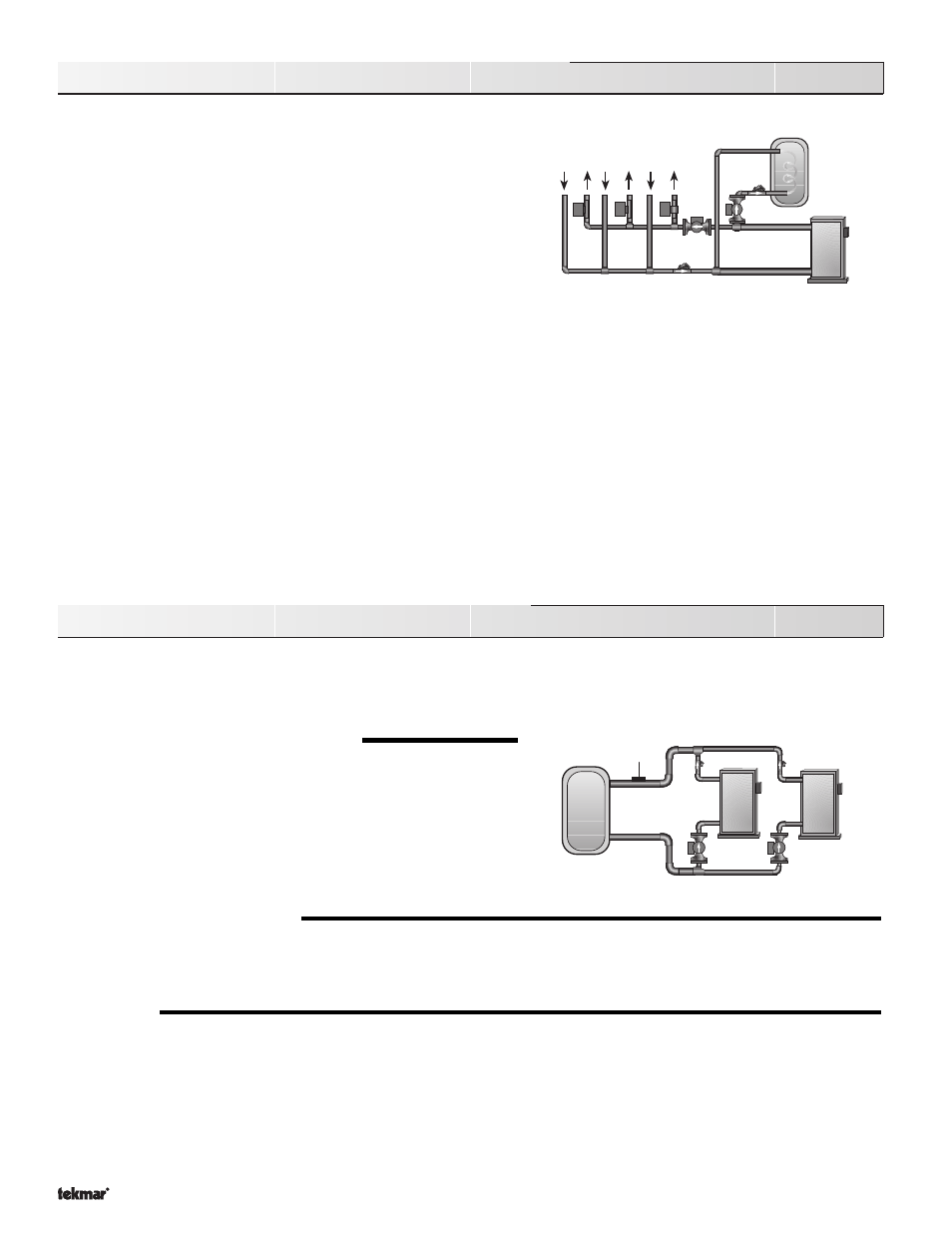

Section C3 —DHW with Low Temperature Boilers (Mode = —1—)

If DHW is to be incorporated into a low temperature system such as a

radiant heating system, a mixing device is often installed to isolate the high

DHW supply temperature from the lower system temperature. If a mixing

device is not installed, high temperature water could be supplied to the low

temperature system while trying to satisfy the DHW demand. This may

result in damage to the low temperature heating system. The 262 is capable

of providing DHW in such a system while ensuring that the low temperature

in the heating system does not exceed its allowed maximum setting.

To prevent high temperature water from being introduced into the heating

system, the boiler pump P1 must be turned off during a call for DHW. To do

this, DHW THRU must be set to PUMP, DHW PRI must be set to Boil and

Boil MIN must be set to OFF.

On a call for DHW, the 262 provides DHW priority by shutting off the boiler pump (P1) for a period of time. This time is based on the

outdoor air temperature as described in the DHW Priority Override section. However, if the

DHW Demand is not satisfied within the

allotted time, the boiler(s) shuts off and the heat of the boiler is purged into the DHW tank.

Once the boiler supply temperature is sufficiently reduced, the DHW pump shuts off. The heating system is turned on for a period of

time to prevent the building from cooling off. After a period of heating, if the

DHW demand is still present, the 262 shuts off the heating

system and provides heat to the DHW tank once again.

For correct operation, close attention must be paid to the mechanical layout of the system. When the 262 turns off the boiler pump (P1),

flow to the heating system must stop. If flow is not stopped, the temperature in the heating system can exceed the maximum desired

temperature and can result in damage to the heating system.

Section C4 —Dedicated DHW (MODE = —2—)

When MODE —2— is selected in the

Adjust menu a number of menu and control operations change. The boiler staging logic is modified

for improved response to dedicated DHW loads. Connection of the outdoor sensor is no longer mandatory. If both an external and an

internal demand are used at the same time, the control displays an error message and stops DHW generation.

INTERNAL DEMAND (DHW SENS = DHW)

When the DHW SENS item is set to DHW, the 262 looks for a DHW sensor

on the

Com and the DHW terminals (19 and 20). When the temperature at

the DHW sensor drops 1/2 of the DHW DIFF setting below the desired

temperature, the

DHW Demand pointer turns on in the LCD. The DHW

TANK setting is used to set the desired DHW storage tank temperature. An

advantage to using the DHW sensor is that the control is able to display the

current DHW tank temperature as well as recording the highest and lowest

DHW tank temperatures.

DHW DIFFERENTIAL (DHW DIFF)

When using the 262 control in MODE —2— operation, a differential setting that operates 1/2 above and below the DHW TANK is

selectable. A domestic hot water sensor is required (DHW SENS = DHW) to be connected to terminals

DHW & Com (19 and 20). If the

differential setting is small, a more precise tank temperature will be maintained, but the boiler(s) may fire more frequently.

DHW DEVICE

While MODE —2— is selected, the

Boiler Pump (Boil P1) contact is used to control the flow of heated water to the DHW tank. The DHW

Pump contact may be used to control a recirculation pump. This pump will run continuously when the control is in

Occupied, and be

off during

UnOccupied.

P

P1

DHW

DHW

Sensor

P