Powers e430 Series Master Mixing Valves User Manual

Page 3

TI430 v3

Page 3

PART DESCRIPTION

REPAIR KIT INCLUDES:

431 Part No.

432 Part No.

433 Part No.

434 Part No.

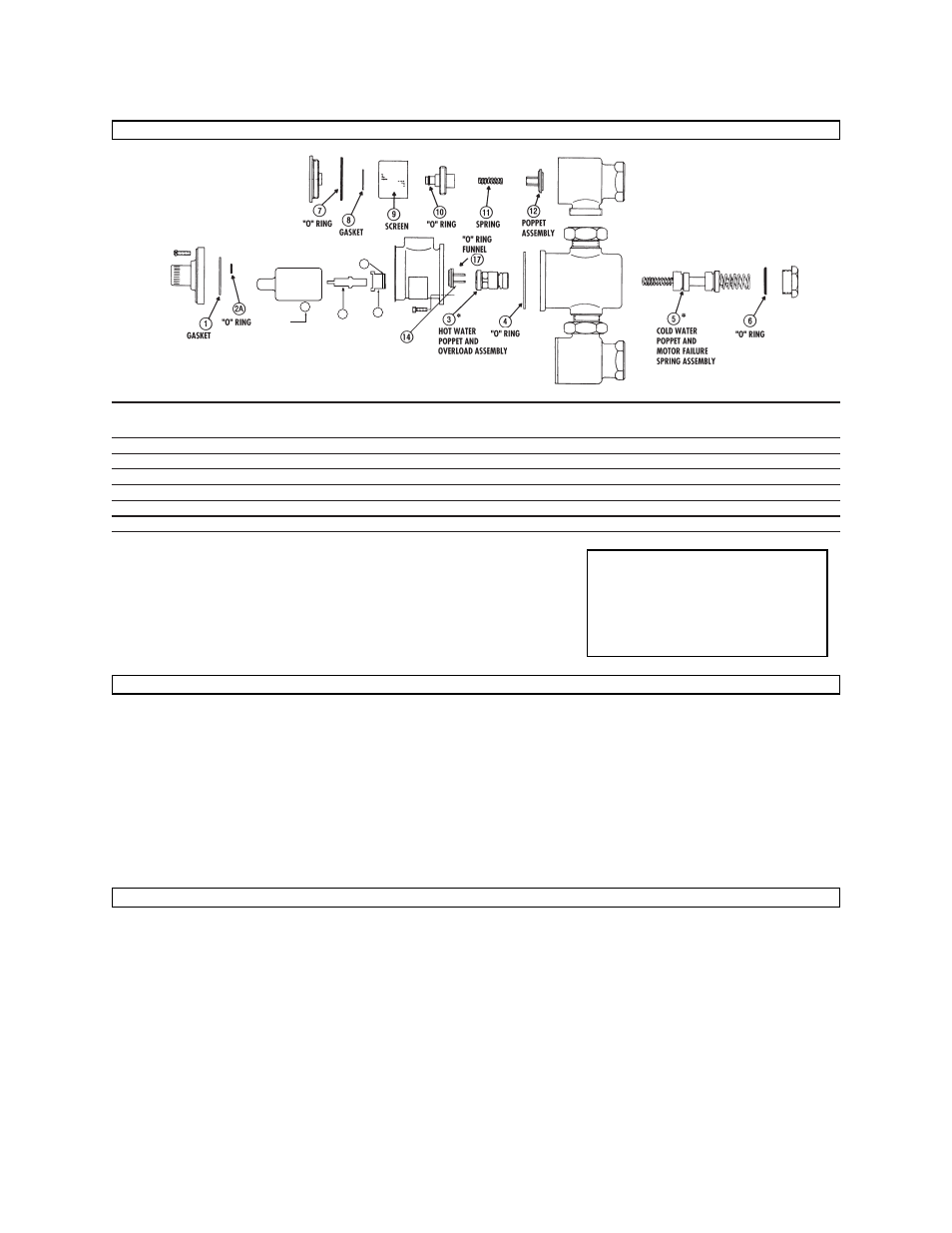

(Numbers below correspond with numbers in Figure 2)

Thermal Actuator

1,2, 4, 13, 15

390-037

390-036

390-065

390-066

Strainer Replacement

7, 8, 9, and 10

230-134

230-134

230-136

230-136

Checkstop Replacement

7, 8, 10, 11, and 12

230-135

230-135

230-137

230-137

Gasket and Disc Replacement

1, 2A, 4, 6, 7, 8, 10, and 12

390-294

390-298

390-302

390-306

Mixing Valve Replacement

3, 4, 5, and 6

390-067

390-068

390-069

390-070

Upgrade Kits for Older Valves**

1, 2, 2A, 4, 13, 14, 15,16, 17

390-016

390-017

390-511

390-512

Strainer and Checkstop Repair Kits contain parts for one (1) pair.

Repair Kits containing “O” Rings include silicone gel for use on “O” Rings during installation.

** For valves shipped prior to 1-1-2001.

REPAIR KITS (Repair Kit Parts)

What to look for if:

• The flow of water is less than desired.

a. Stop valves or supply to Hydroguard not fully open.

b. Clogged checkstop strainer screens.

c. Accumulation of lime deposits around valve seats.

d. Low supply pressures or unusual supply temperatures.

• The flow of water is completely shut off.

a. Stop valves or supply valves are completely closed.

b. Valves downstream from Hydroguard fully closed.

c. Loss of either hot or cold water supply pressure.

• Discharge temperature varies:

a. Very large restriction in outlet flow.

b. Very large drop in inlet pressure.

c. Very large fluctuation of hot water supply temperature.

d. Worn valve seats.

e. Minimum flow requirement not achieved.

MAINTENANCE AND TROUBLESHOOTING

1. IMPORTANT: Flush all piping thoroughly before installing.

2. Valve should be installed close to the hot water supply and

should easily be adjusted and repaired.

3. Remove body screws to turn outlet to any of four positions.

The Hydroguard body can be rotated to any position due to

the union inlets. Note: Make certain the body screws and

unions are tightened securely to prevent leakage.

4. CAUTION: When the Hydroguard supplies tempered water

to self-closing and/or solenoid valves, provide a shock

absorber (Powers Part No. 460-353) on the discharge line.

This protects the Hydroguard thermostatic motor from dam-

age by water shock waves generated by the quick closing

valves.

5. Before use, check maximum discharge temperature.

Reset if necessary.

OPERATION CHECK:

After Hydroguard is installed, make certain the supply stop

valves and strainers are free and clean and ready for operation

by disassembling checkstops as shown in "Servicing", steps 1,

2, and 3.

INSTALLATION INSTRUCTIONS

OVERLOAD

ASSEMBLY

ACTUATOR

STEM

ADAPTER

2

16

"O" RING

15

13

Figure 2

CALIFORNIA PROPOSITION 65 WARNING

WARNING: This product contains chemicals

known to the State of California to cause cancer

and birth defects or other reproductive harm.

(Installer: California law requires that this warning

be given to the consumer.)

For more information: www.wattind.com/prop65