Powers e430 Series Master Mixing Valves User Manual

Technical instructions

The Series 430 Hydroguard thermostatically blends hot and

cold water to deliver mixed water at the desired temperature,

compensating for temperature, pressure, and flow changes in

the supply lines, and reduces flow upon water supply failure.

The delivery is adjustable between 40°F and 160°F (4-71°C).

Maximum Pressure Differential . . . . . . . . . . . . .100 psi (689 kPa)

Maximum Static Pressure . . . . . . . . . . . . . .125 psig (861.25 kPa)

Maximum Hot Water Temperature . . . . . . . . . . . . . .200°F (93°C)

Minimum Hot Water Supply Temp . .15°F (8°C) Above Set-Point

Temperature Adjustment Ranges* . . . . . . . . .40°-160°F (4°-71°C)

Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ASSE 1017

Certified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CSA B125

* Note: Low limit cannot be less than the cold water temperature. For best

operation, hot water should be at least 15°F (8°C) above desired set point.

TECHNICAL INSTRUCTIONS

431/432/433/434 Hydroguard

Master Mixing Valves

A Watts Industries Co.

DESCRIPTION

SIZING

SPECIFICATIONS

Table 1- Flow Capacity in US gpm at 50-50 Mixed Ratio

Model Min Flow Min Flow

Pressure Drop Across Valves in psi

Rate* to ASSE 1017

5

10

20

30

45

60

75 100

431

0.5 gpm

4.0 gpm

7.5

11

16

20

25

29

33 38.5

432

0.5 gpm

7.0 gpm

15

20

30

36

45

52

58

67

433

0.5 gpm

10.0 gpm

24

35

51

64

80

93 105 123

434

0.5 gpm

15.0 gpm

40

55

82

101 125 146 165 190

* Minimum flow when Hydroguard is installed at or near hot water source with recirculated tempered water with

continuously operating recirculating pump.

Flow Capacity in lpm at 50-50 Mixed Ratio

Model Min Flow Min Flow

Pressure Drop Across Valves in kP

A

Rate*

to ASSE 1017

34

69

138

207

310 414

517 689

431

1.89 lpm

15 lpm

28.4

41.6

60.6

76.0

94.6 109.8 125.0 145.7

432

1.89 lpm

26 lpm

56.8

76.0 113.5 136.2 170.3 197.0 219.5 253.5

433

1.89 lpm

38 lpm

1.5

2.2

3.2

4.0

5.0

5.9

6.6

7.8

434

1.89 lpm

57 lpm

2.5

3.5

5.2

6.4

7.9

9.2

10.0

12.

* Minimum flow when Hydroguard is installed at or near hot water source with recirculated tempered water with

continuously operating recirculating pump.

WARNING: TO INSURE THE ACCURATE AND RELIABLE

OPERATION OF THIS PRODUCT, IT IS ESSENTIAL TO:

• Properly size each valve based on the individual application

• Properly design the recirculation system to minimize pressure

and temperature variations

• Conduct an annual maintenance program to insure proper

operation of all critical components

FAILURE TO COMPLY WITH PROPER INSTALLATION

INSTRUCTIONS COULD CONTRIBUTE TO VALVE FAILURE,

RESULTING IN INJURY OR DEATH.

Table 1, Capacity Tables, present the Hydroguard discharge capacity in GPM and I/m for various pressure differentials (the difference

between the lowest inlet pressure and the discharge pressure at the Hydroguard).

Typical Flow

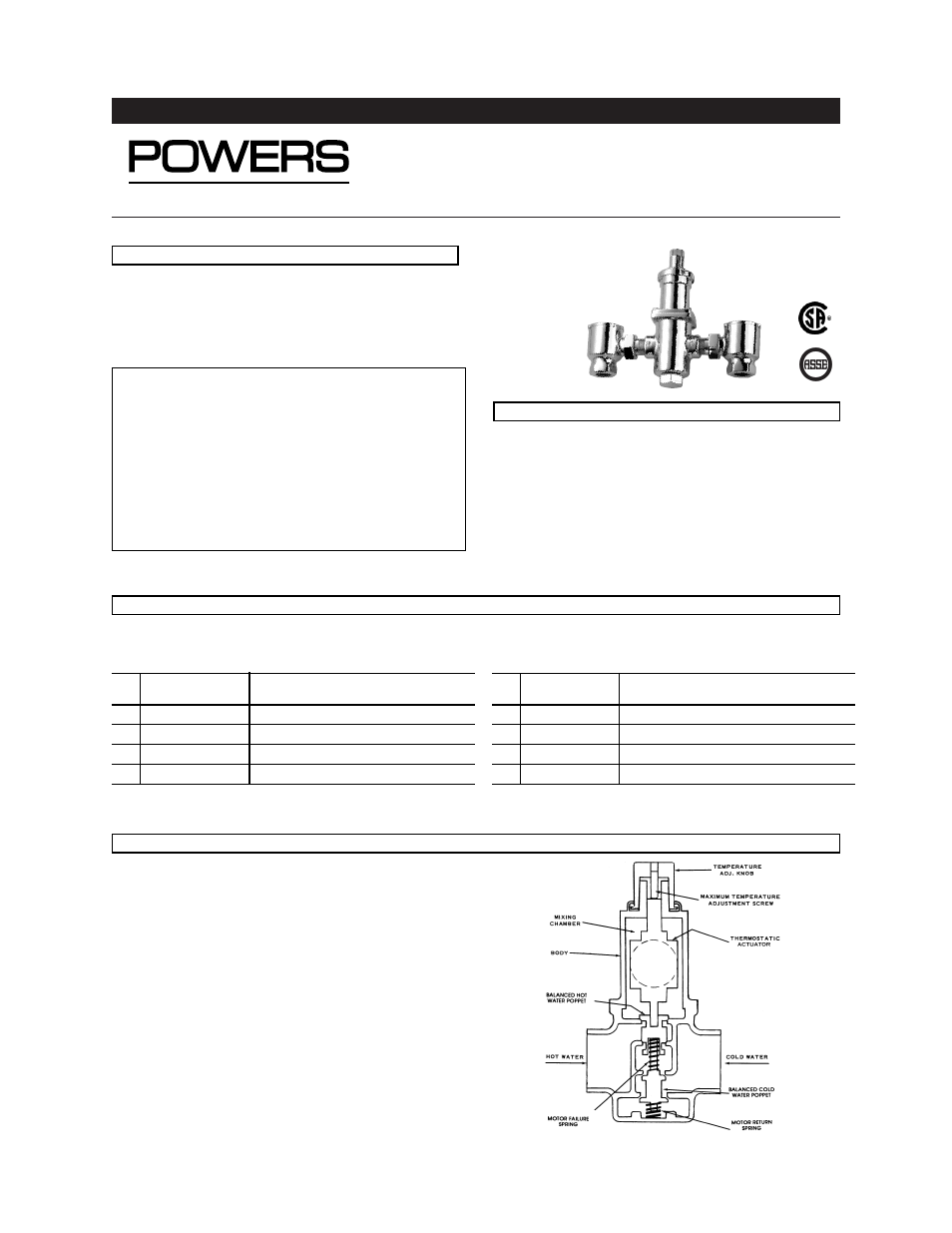

Hot and cold water supplies enter Hydroguard at indicated ports,

(see Figure 1) then flow past their respective balanced poppet plug

and seats. Next, hot and cold water flow is directed to the mixing

chamber where the thermostatic actuator is located.

Temperature adjustment knob moves the actuator to determine the

discharge temperature.

With a rise in discharge temperature due to pressure or tempera-

ture fluctuation on the inlet, the actuator expands, decreasing flow

of hot water. The reverse occurs with a drop in discharge tempera-

ture.

• Cold water supply failure – causes actuator to expand allowing

the motor to seat hot water poppet.

• Hot water supply pressure failure – causes actuator to contract

allowing return spring to seat cold water poppet.

OPERATION

Figure 1

Form

TI430 v3

OUTLET