Installation, Maintenance – Powers 596 SI Flowrite II Heavy Duty Control Valves User Manual

Page 7

Form TI 596SI v2

Page 7

INSTALLATION

Inspection

Inspect the package for damage. If damaged, notify the appropriate carrier

immediately.

If undamaged, open the package and inspect the device for obvious

damage. Return damaged products.

Requirements

• Pipe wrenches

• Flange gaskets, bolts/nuts

• Installer must be a qualified, experienced technician

CAUTION!

• Install the valve with the flow in the direction of the flow arrow.

• Do not exceed the ratings of the device.

• Avoid locations where excessive moisture, corrosive fumes, or

vibration are present.

Mounting/Orientation

1. The valve should be mounted in a location that is within the

ambient limits of the actuator. When selecting a location, allow

sufficient room for valve linkage, actuator, and other accessories

and for service of the product.

2. The preferred mounting position for the valve is with the valve

stem vertical above the valve body. Avoid mounting the valve so

that the valve stem is below horizontal.

3. On steam applications where the ambient temperature

approaches the limit of the actuator, the valve stem should be

mounted 45° from vertical.

Flanged Connection

The 596SI series flanged valve bodies conform to American Standard 125

Lb. Cast Iron Pipe Flanges. The companion flanges (not provided) should

be the same specification as the valve. The 125 lb. flanges have plain flat

faces and should not be bolted to a raised faced flange.

1.

All parts should be clean to assure the best results.

2.

The pipe with the companion flanges installed should be

properly supported and aligned. Be sure the companion flange is

flush with the face of the valve body flange and lined up

squarely.

3.

Use a gasket material (not provided) that is recommended for

the medium being handled.

CAUTION! Do not apply pipe dope to the valve flange, gasket,

or companion flange.

4.

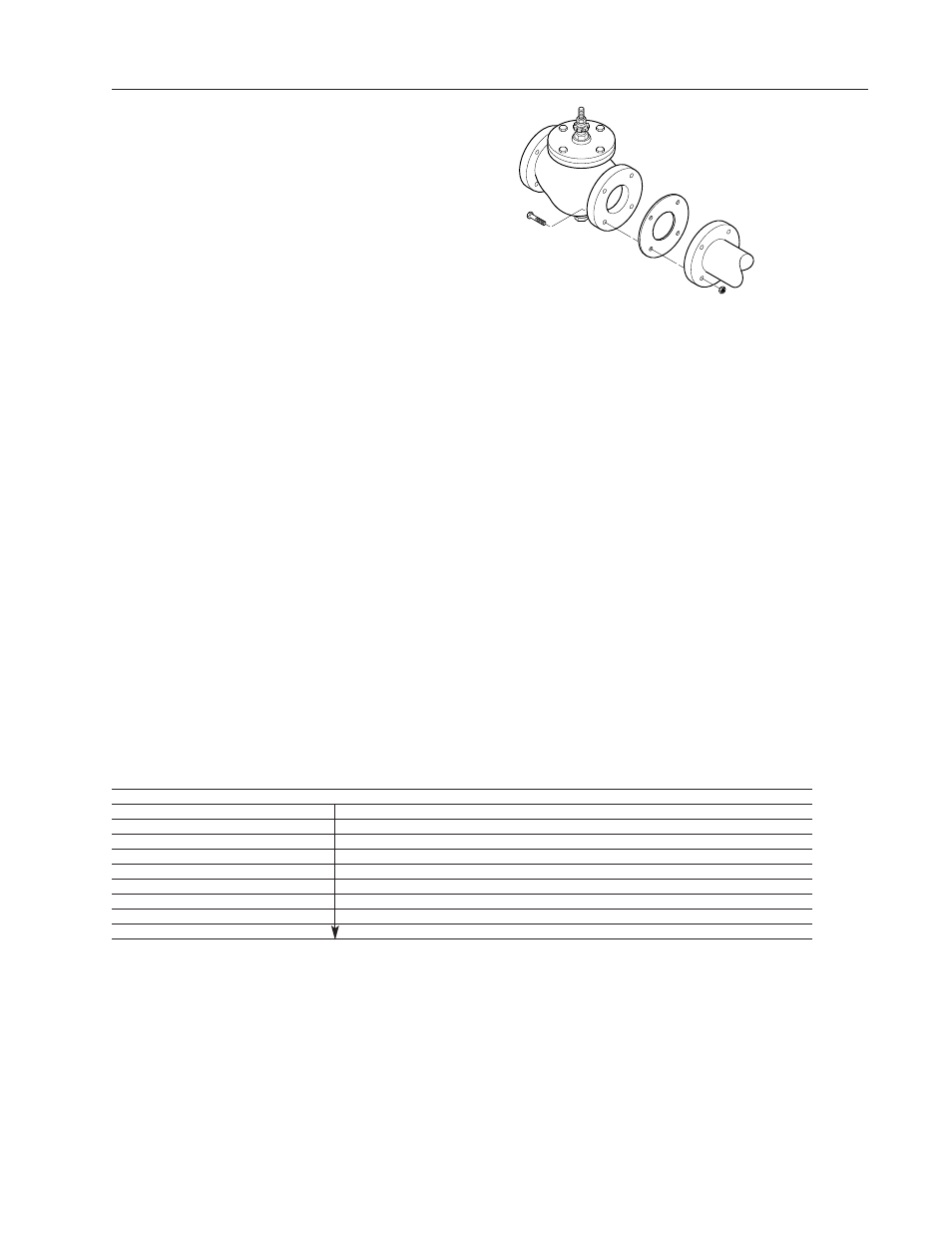

See Figure-5 for flange and flange bolt details.

Figure-6 shows the proper way a flanged valve should be

mounted.

MAINTENANCE

Regular maintenance of the total system is recommended to assure sustained performance. See Table-6 for maintenance kit part numbers.

Table - 6 Maintenance Kits for 596SI Valves

Valve Description

Replacement

Replacement

Valve Repair Kit*

Packing Assembly

Gaskets

2.5 Normally Closed

596 Pack

596250G

SIGOBCTK

3 Normally Closed

596300G

SIHOBCTK

4 Normally Closed

596400G

SIJOBCTK

5 Normally Closed

596500G

SIKOBCTK

6 Normally Closed

596600G

SILOBCTK

2.5 Normally Open

596250G

SIGOBXTK

3 Normally Open

596300G

SIHOBXTK

4 Normally Open

596400G

SIJOBXTK

5 Normally

Open

596500G

SIKOBXTK

6 Normally

Open

596600G

SILOBXTK

* Kit includes replacement packing and stem & plug assembly.

Water System Maintenance

All systems are susceptible to valve and system problems caused by improper

water treatment and system storage procedures. These guidelines are

provided to help avoid valve and water system problems resulting from

improperly treated water or storage procedures and to obtain maximum life

from the valves.

Durability of valve stems and packings is dependent on maintaining non-

damaging water conditions. Inadequate water treatment or filtration can

result in corrosion, scale, and abrasive particle formation. Scale and

particulates can result in stem and packing scratches and can adversely affect

packing life and other parts of the hydronic system.

To maintain non-damaging conditions, follow these guidelines:

• Clean the system prior to start up.

• Use filtration equipment where needed.

• Properly store off-line systems and monitor water treatment results.

• Follow the advice of a water treatment professional.

Valve

Body

Gasket:

Supplied

by Others

Companion

Flange

Figure 6 - Installation of

Flanged End Valves