Valve sizing and selection (water), Cavitation limitations on valve pressure drop – Powers 596 SI Flowrite II Heavy Duty Control Valves User Manual

Page 3

Form TI 596SI v2

Page 3

VALVE SIZING AND SELECTION (WATER)

The sizing of a valve is very important if it is to render good service. If it

is "undersized", it will not have sufficient capacity. If it is "oversized", the

controlled variable may cycle, the trim can be exposed to excessive wear or

wire drawing, and you could expect reduced valve life. To help select the

right valve, it is important to understand your application and its variables

(controlled fluid, temperatures, pressures, min/max load, etc.). When

your system variables are known and you have calculated actual demand, it

is possible to select the right Powers valve for your application. The

following technical data should help you in selecting a valve for your water

control applications. For fluid applications other than water, contact

Powers’ application engineering.

On/Off Control:

These types of applications are normally line sized to reduce pressure drop

and pump size. In these applications it is important to verify valve seat

leakage will not result in system overheat or damage. If this is a concern, it

is necessary to take precautions to alleviate this potential problem.

Proportional Control:

In applications where the close-off pressure at the valve is below 20psig,

use a pressure drop of 5psi.

In applications where the close-off pressure at the valve is above 20psig, it

is generally recommended to take 25-50% of the system pressure drop at

the control valve to maintain good valve/system performance. Certain

applications can successfully utilize lower pressure drops across the valve

(5-25%) if system fluctuations are kept to a minimum. If not, the valve is

considered oversized it will not effectively throttle until it is nearly closed

thereby resulting in poor control.

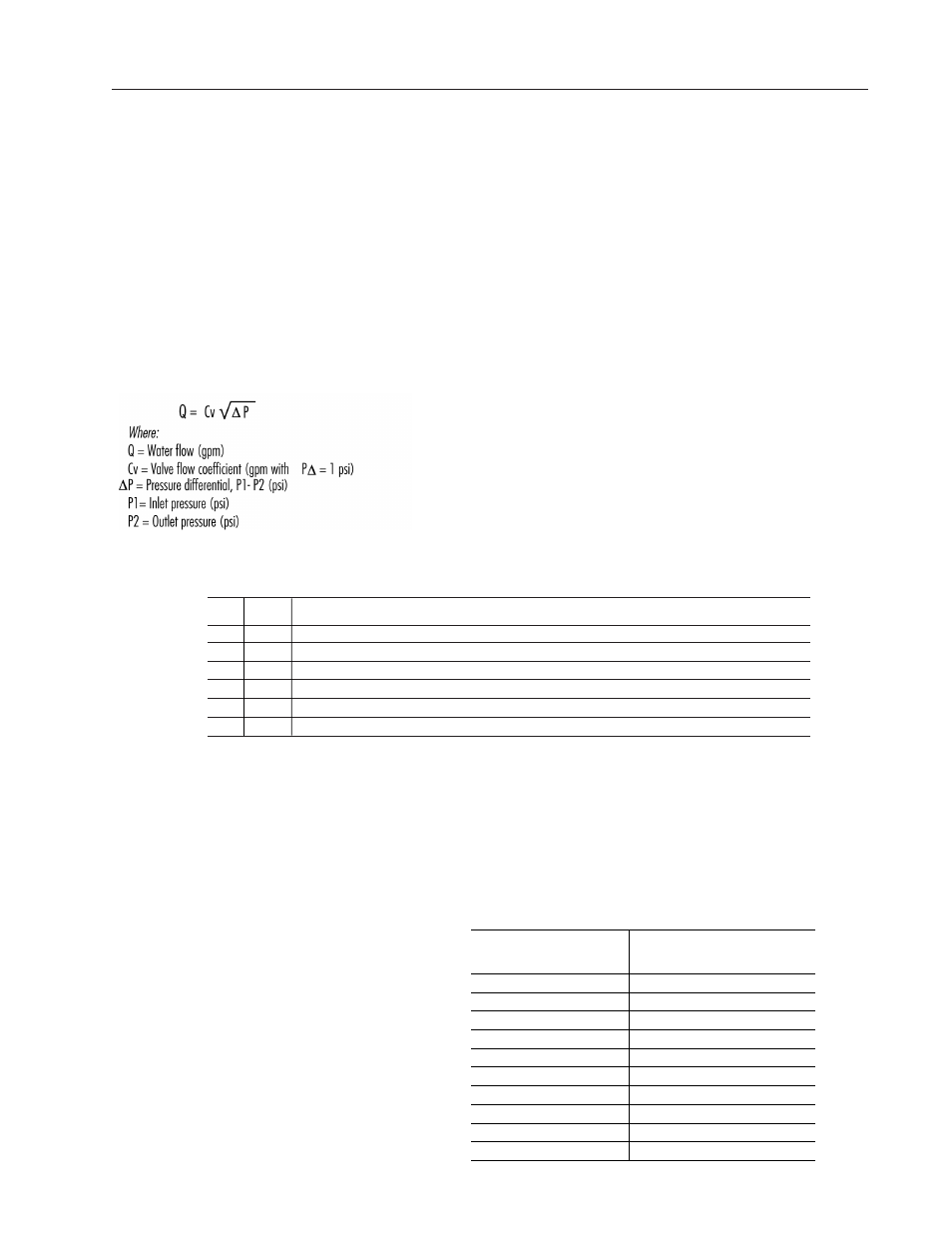

Refer to the following table for flow….

Table - 1

Water Capacity in Gallons Per Minute

Valve Cv

Size

Rating

Differential Pressure (

∆

P in psi)

5

10

20

30

40

50

60

70

80

90

100

125

2.5

65

145

206

291

356

411

460

503

544

581

617

650

727

3

85

190

269

380

466

538

601

658

711

760

806

850

950

4

145

324

459

648

794

917

1025

1123

1213

1297

1376

1450

1621

5

235

525

743

1051

1287

1486

1662

1820

1966

2102

2229

2350

2627

6

350

783

1107

1565

1917

2214

2475

2711

2928

3130

3320

3500

3913

CAVITATION LIMITATIONS ON VALVE PRESSURE DROP

A concern in high temperature water systems is the potential for cavitation/flashing, which is caused by the downstream pressure being lower than that of the

vapor pressure of the fluid. This basically causes the water to "boil" and can result in reduced flow/capacity, excessive noise, vibration, wear and should be

avoided if possible. Use the following equation to estimate the maximum allowable pressure drop across the valve:

Pmax = 0.5 (P1 – Pv)

Where:

Pmax = Maximum allowable pressure drop

P1 = Absolute inlet pressure (psia)

Pv = Absolute vapor pressure (refer to psia - Table 2)

Absolute pressure = gage pressure + 14.7

Table-2

Vapor Pressure of Water Table

Water Vapor

Water Vapor

Temp.

Pressure

Temp.

Pressure

(°F)

(psia)

(°F)

(psia)

40

0.12

140

2.89

50

0.18

150

3.72

60

0.26

160

4.74

70

0.36

170

5.99

80

0.51

180

7.51

90

0.70

190

9.34

100

0.95

200

11.53

110

1.28

210

14.12

120

1.69

220

17.19

130

2.22

230

20.78