Powers ETV400 Emergency Tempering Valves with Internal Cold Water Bypass User Manual

Page 3

Index

Description

Part No.

ETV200

ETV400

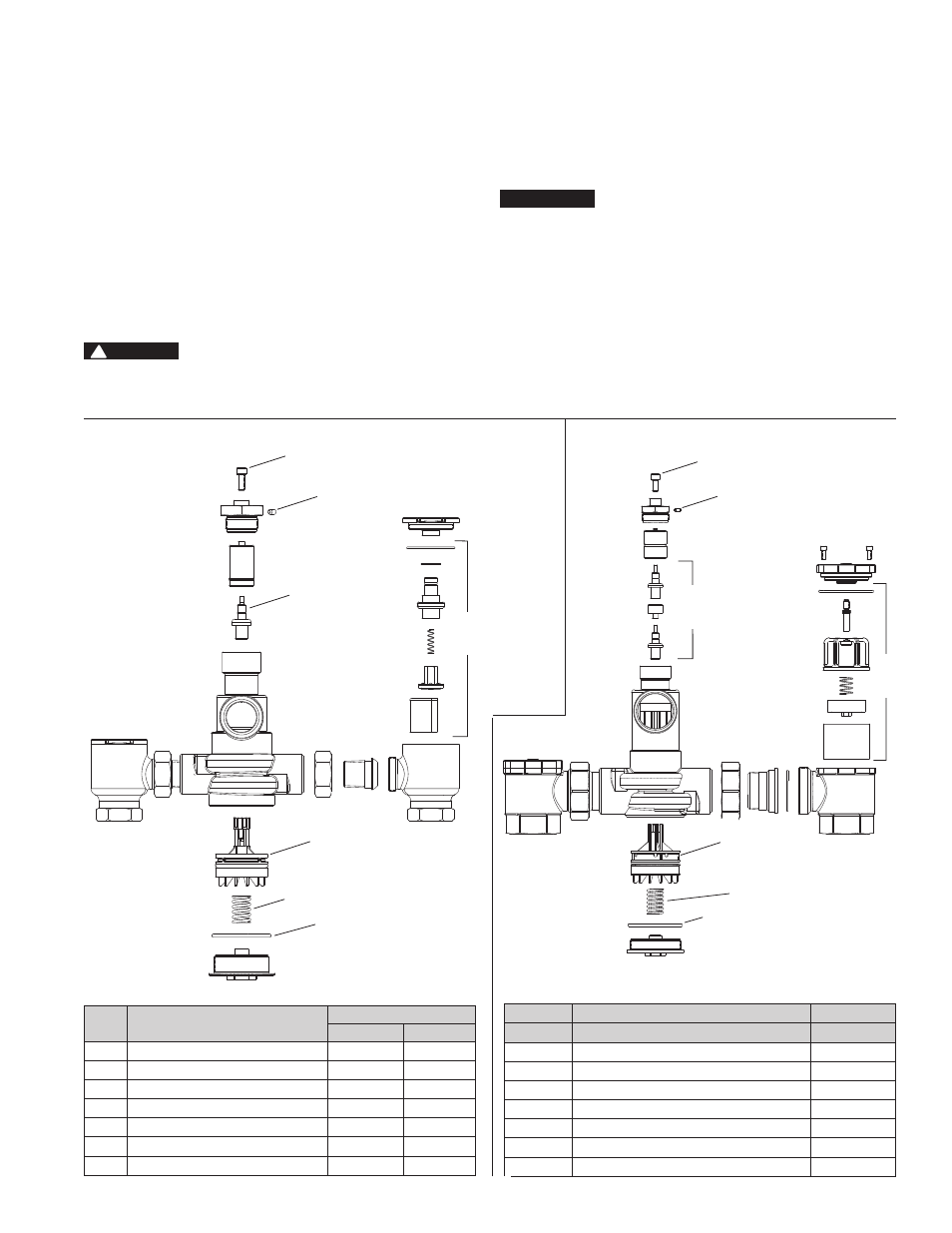

1

Temperature Adjustment Screw

390 777

390 787

2

Adjustment Locking Screw

390 795

390 795

3

Actuator

390 808

390 810

4

Plunger Kit

390 802

390 803

5

Spring

390 620

390 162

6

O-Ring

1101575

2101003

7

Checkstop Rebuild Kit

390 800

390 801

ETV500

Index

Description

Part No.

1

Temperature Adjustment Screw

390 787

2

Adjustment Locking Screw

390 795

3

Actuator Kit

390 815

4

Plunger Kit

390 816

5

Spring

390 162

6

O-Ring

2101003

7

Checkstop Rebuild Kit

390 811

3

Disassembly

1. Close supply valves and/or checkstops

2. Remove valve from its outlet piping. Work should be performed on a

clean table or workbench.

3. To remove thermal actuator from top

a) Loosen adjustment locking setscrew.

b) Remove bonnet and overload assembly.

c) Lift out thermal actuator.

d) Assemble in reverse order

4. To remove the plunger assembly from bottom

a) Remove the bottom cap.

Spring is under tension.

b) Pull out spring

c) Pull out plunger using a pair of pliers.

d) Reassemble in reverse order.

After reassembling go back to thermal actuator section and make sure it

is sitting in its holder properly.

Inspection

1. Inspect body for any damage, deposits or pitting. Clean or replace as

necessary.

2. Check the actuator for proper operation at room temperature. Hold

actuator between your finger and thumb. Apply force on end of stem.

Measure the entire length of the actuator and then place it in the hot

water (105-110°F) for 10 seconds. Actuator stem should extend at

least 1/8" longer than when at room temperature.

Due to the safety nature of this product, we recommend

removal of the valve by a licensed contractor and full

inspection of all components whenever the valve is disas-

sembled for any reason. Temperature must be checked and

adjusted. For temperature adjustment see Adjustment &

Testing section.

Disassembly and Inspection

n

2

3

4

4

5

5

6

6

7

7

3

ETV 200

ETV 400

ETV 500

Parts List

n

1

1

2

NOTICE

CAUTION

!