Powers 744 Series Accritem Rigid and Remote Bulb Blind Controllers - Rigid Bulb User Manual

Page 3

3

Installation Instructions

n

General Instructions

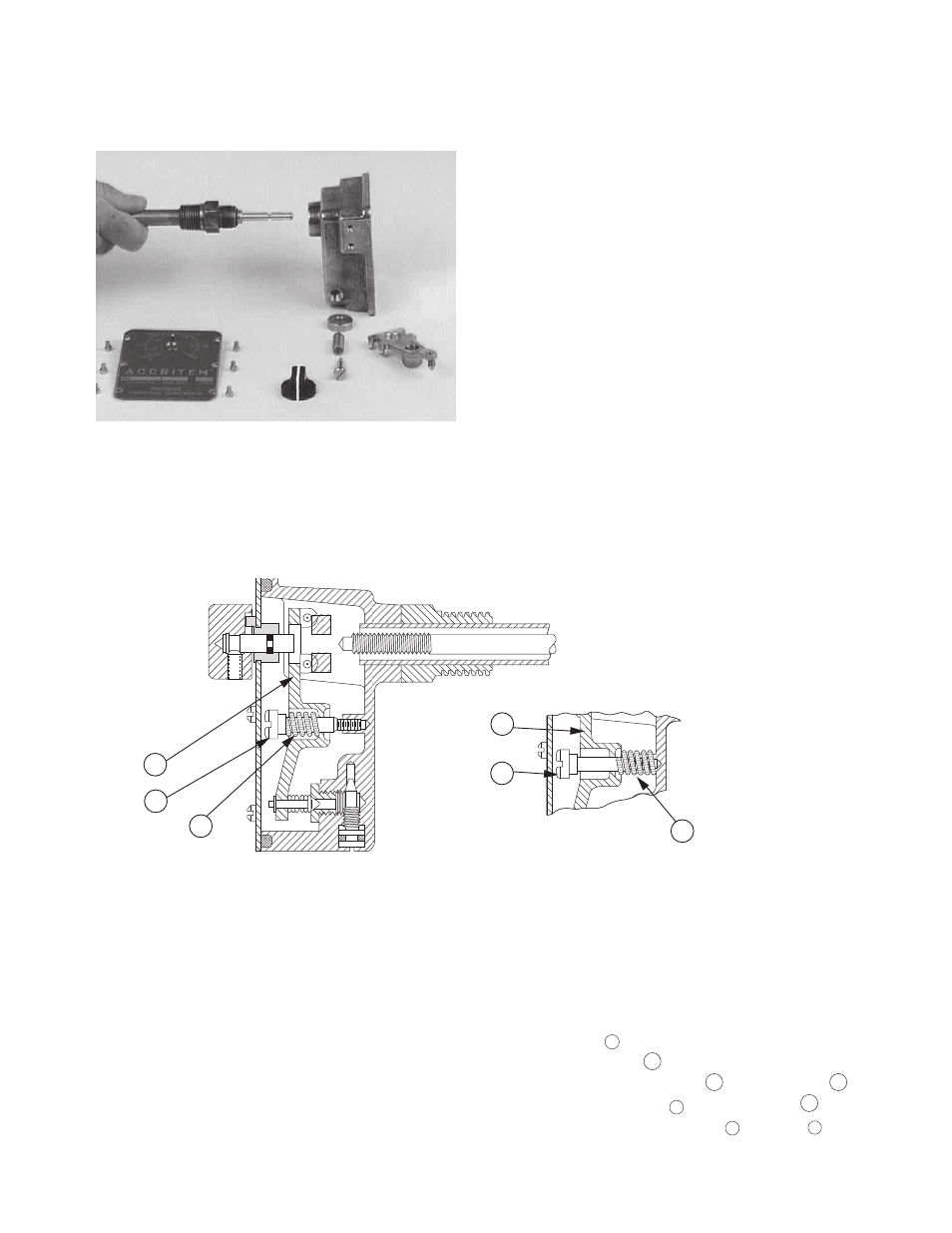

Figure 5.

to disassemble and replace sensitive tube assembly:

The Accritem Controller requires a clean, reliable supply

of compressed air or cold water at room temperature and

15 tgo 20 pounds of pressure. Other fluids may be used,

such as gas, oil, etc., providing provision is made for safe

disposal.

Figure 6

The parts in Figure 7 are identified by letter in order of disas-

sembly. For item number reference, see Parts Drawing: A (item

3) adjusting knob with set screw, B (item 10) cover screws, C

(item 2) cover plate, D (item 8) spring retainer screw, E (item 9)

lever spring, F (item 21) lever pivot, G (item 7) lever.

Always locate the controller as close as possible to the

controlled device. The piping between the controller and

controlled device (valve or damper motor) should be 1/8"

NPT brass pipe or 6.4 mm (1/4") OD copper tubing.

Difference in height between Accritem controller and con-

trolled device should be kept to a minimum. When controller

is below controlled device, elevation cannot exceed 3 m (10")

with 104 kPa (15 psi) supply pressure. If controller is above

controlled device, adjust springs on valve or damper motor to

compensate for static head pressure.

Pressure Controller for Use with Water

Set pressure at 104–138 kPa (15–20 psi) when water is flowing.

Clean strainer at regular intervals.

Both Air and Water Controllers

To disassemble (Refer to Parts Drawing and Figure 5):

1. Remove knob

3

after loosening its set screw.

2. Remove cover plate

2

.

3. Remove spring retainer screw

8

and lever spring

9

.

4. Back out one lever pivot

20

and remove lever

7

.

5. Unscrew sensitive tube assembly

20

from body

1

.

REVERSE ACTING

SPRING LOCATION (behind lever)

8

DIRECT ACTING

SPRING LOCATION (in front of lever)

Lever

Spring

Retainer

Screw

Spring

Retainer

Screw

9

7

Lever

9

8

7

Select sensitive element location with care to insure satisfac-

tory results. Bulb must project entirely into the liquid or air being

controlled.

Flush or blow out all lines before making final connections. Put

supply pressure through all control lines and check for leaks.

iNStALLAtiON FOR AiR OpERAtiON

Controller should normally be installed in horizontal position;

however, other positions may be used if the supply and control

connections are parallel with the ground and calibration is

checked after installation.

iNStALLAtiON FOR WAtER OpERAtiON

Controller should normally be installed in horizontal position with

drain connection at bottom. For positive drainage at all times,

drain piping should be 3/8" minimum.

tO CHANgE CONtROLLER ACtiON

(See Figures 6 and 7)

1. Turn adjusting knob clockwise to remove tension.

2. Remove adjusting knob and cover.

3. Remover lever spring retainer (D) and spring (E).

4. Relocate lever pivots (F).

5. Turn lever pivots to be snug without binding.

6. Replace lever spring retainer (D) and spring (E).

7. Replace cover and adjusting knob.

8. Recalibrate.