Powers 744 Series Accritem Rigid and Remote Bulb Blind Controllers - Rigid Bulb User Manual

Page 2

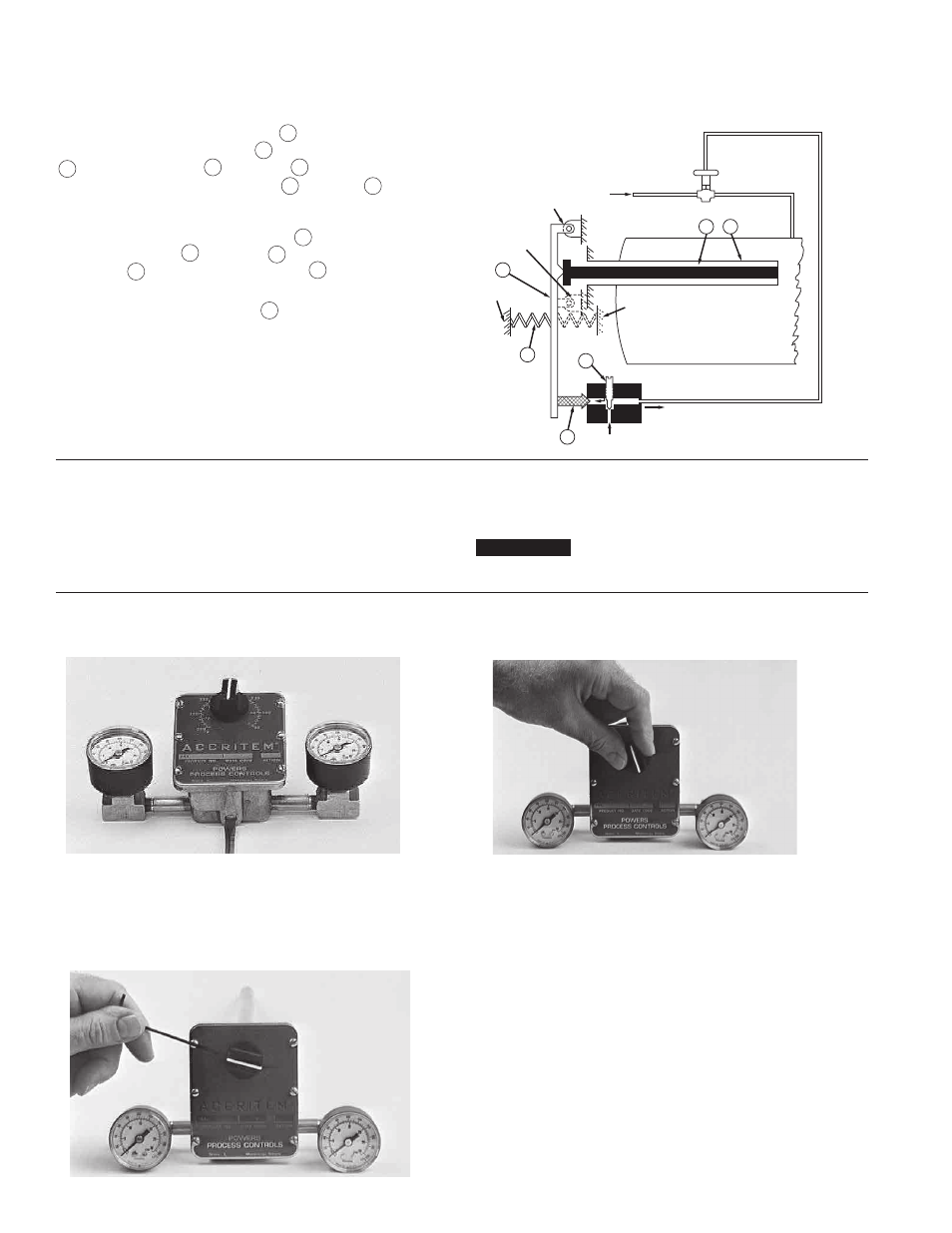

Direct Action Controller

A temperature change in the medium being controlled creates a

change in length of the sensitive tube

1

. An increase in tempera-

ture lengthens the sensitive tube

1

and moves the Invar rod

2

away from the lever

3

. The lever

3

, which pivots at Point

A, is moved to open the exhaust valve

4

by spring

5

. This

permits the supply (air or water) (S) to increase the pressure in the

control line (R) and close the normally-open valve. A decrease in

temperature shortens the sensitive tube

1

and moves the Invar

rod against the lever

3

. The lever

3

moves against the pres-

sure spring

5

, to open the exhaust valve

4

. This exhausts the

pressure in the control line and opens the valve.

The sensitivity adjustment screw

6

regulates the rate of flow

of the supply air (or water) to the controller to a change in tem-

perature. Turning the screw clockwise increases the sensitivity

by reducing the flow and increasing the response time. Turning

the screw counterclockwise decreases the sensitivity by

increasing the flow and reducing the response time.

Also see Figure 8 on page 7.

Figure 1

Operation Instructions

n

2

The sensitivity of the Accritem controller is adjusted by turn-

ing the restriction screw (Figure 2). (The restriction screw is

factory-set for air operation.) For water operation, the restriction

screw should be opened a minimum of 1/2 turn and controller

recalibrated. Restriction screw must never be fully closed. Make

Sensitivity

n

adjustments slowly, allowing about two (2) minutes after each

adjustment for the controller to balance.

Calibration

n

Set restriction screw for desired sensitivity. Air: 1/8 turn

from closed (minimum). Water: 1/2 turn from closed

(minimum).

Turn adjusting knob until 52 kPa (7-1/2 psi) control pres-

sure shows on gauge. Read temperature at bulb with

an accurate thermometer.

Loosen set screw and turn adjusting knob to indicate

temperature at bulb. Tighten set screw. Set controller for

desired control temperature.

Figure 2

Figure 3

Figure 4

Flowrite Valve

(Normally Open)

Exhaust Air

Tank

A

B

D

C

R

S

4

5

3

2

1

6

Positions “B” and “D” (dotted) show

pivot point (“B”) and spring when

controller is REVERSE acting.

Positions “A” and “C” (solid) show pivot

point (“A”) and spring when controller is

DIRECT acting.

NOTICE

If sensitivity is changed, controller must be recalibrated.