Powers 744 Series Accritem Rigid and Remote Bulb Blind Controllers - Remote Bulb User Manual

Page 2

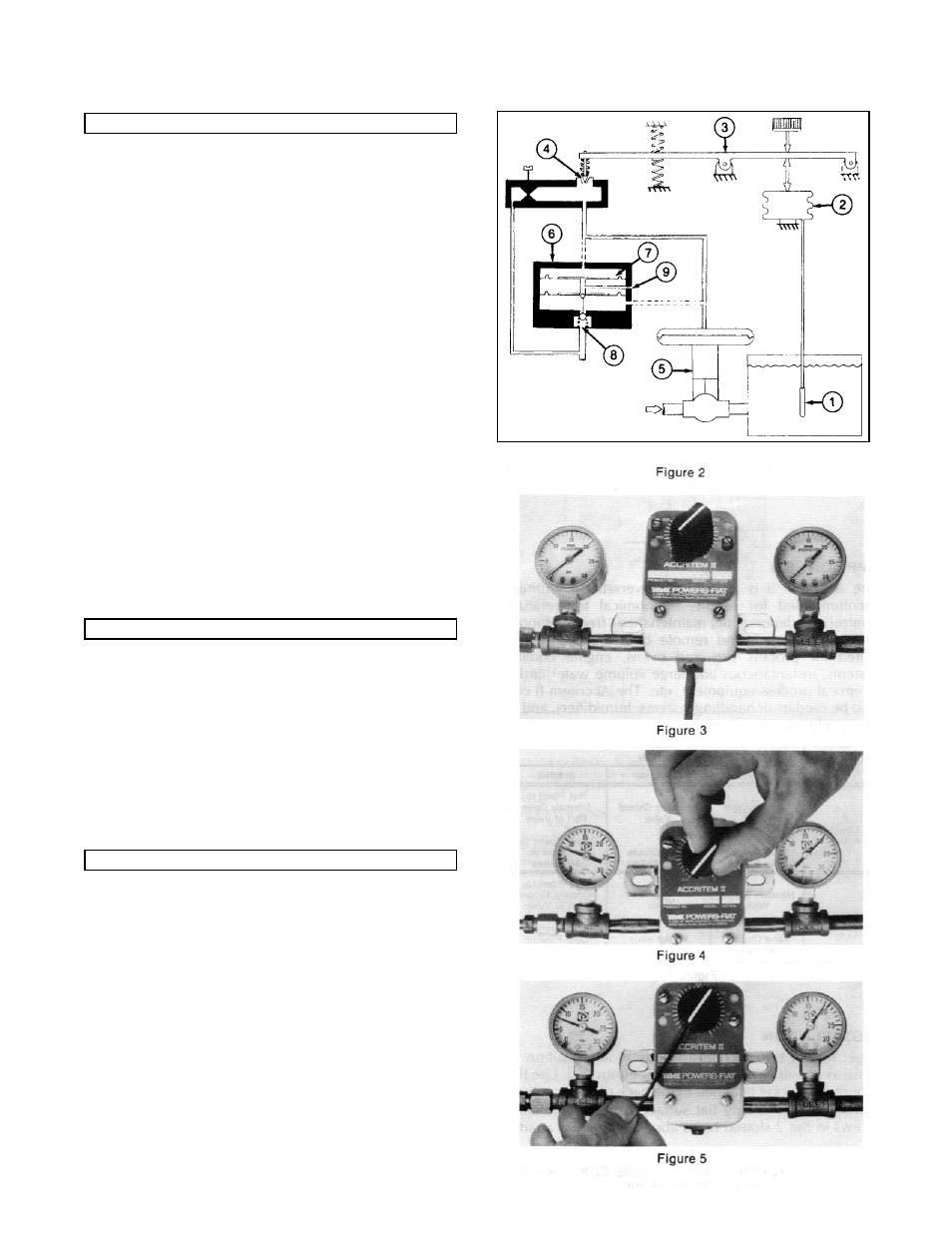

Non-Relay Model: Direct Acting (See Figure 2)

A temperature change in the control medium creates a

change in the liquid filled temperatures sensor (1) which

causes the bellows (2) to expand and push the lever arm (3).

The lever moves to close the exhaust valve (4). This permits

the supply air to increase the pressure in the control line and

close the normally open valve (5). A decrease in temperature

lowers the pressure within the bellows allowing the pressure

spring to push on the lever, opening the exhaust valve. This

lowers the pressure in the control line and opens the valve.

Relay Model:

In the relay equipped controllers, as the temperature increas-

es and the lever moves to close off the exhaust valve, the

restricted supply air moves through the control line to the

pilot relay (6). As the pressure increases in the upper air

chamber (7), the diaphragm assembly moves to open the

supply valves (8) thereby allowing a greater volume of supply

air through the control line to the valve (5).

A decrease in temperature causes the lever to open the

exhaust valve, venting air from the upper air chamber.

Diaphragm assembly assumes its normal position thereby

allowing the spring to close the supply valve. Control line

pressure is relieved through the exhaust port (9).

The sensitivity of the Accritem II is adjusted by turning the

restriction screw which is located on the bottom of the

controller, (see Figure 3). The Restriction screw must never

be tightly closed. Factory setting is about 1/4 turn open.

Turning the screw counter-clockwise decreases sensitivity,

reducing the response time. Make adjustments slowly, allow-

ing about two minutes after each adjustment for the con-

troller to balance.

NOTE: When sensitivity is changed, the controller dial and

knob should be re-calibrated.

The Accritem II must be calibrated to match the required out-

put pressure. For example: a valve with 3 to 13psi (21 to 90

kPa) range and a midpoint of 8psi (55 kPa) will require the

Accritem to pass 8psi (55 kPa) control pressure, (see Figure

4), when the knob points to a dial temperature that is the

same as the bulb temperature. To calibrate the instrument,

set the adjustment screw for desired sensitivity. Turn adjust-

ment knob on controller until required pressure shows on

control gauge and process temperature has enough time to

stabilize. Then take a recording of temperature at the bulb

location with an accurate thermometer. Loosen set screw

and turn adjusting knob to indicate temperature at bulb, (see

Figure 5). Tighten set screw. Set Controller for the desired

process temperature.

TI TC744-2 Page 2

OPERATION

SENSITIVITY ADJUSTMENT

DIAL CALIBRATION