Aileron and flap servo installation – E-flite F-4 Phantom 32 DF User Manual

Page 7

7

E-flite F-4 Phantom 32 DF Assembly Manual

5. Once the CA has fully cured, gently pull on

the wing and aileron (and flap) to make sure the

hinges are glued securely. If not, reapply thin CA

to any hinges that are not secure. Flex the aileron

and flap through their range of motion a number

of times to break in the hinges. This will reduce the

initial load on the servo for your first flights.

6. Repeat Steps 1 through 5 to install the remaining

aileron and flap hinges.

Aileron and Flap Servo Installation

Required Parts

Wing panel (right and left)

Transmitter

Receiver

Receiver battery

Servo with hardware (4)

Hardwood block, 15mm x 13mm x 6mm (8)

2mm x 8mm self-tapping screw (16)

Required Tools and Adhesives

Phillips screwdriver: #1

Hobby knife with #11 blade

Pencil

Razor saw

Thin CA

5-minute epoxy

Mixing cup

Mixing stick

Drill

Drill bit: 5/64-inch (2mm)

Side cutter

Pin vise

Felt-tipped pen

Medium grit sandpaper

When centering the flap servo, begin by setting

the throws at the transmitter to 0% for both the

up and down flap positions. This should be done

for both 2- and 3-position flap switches.

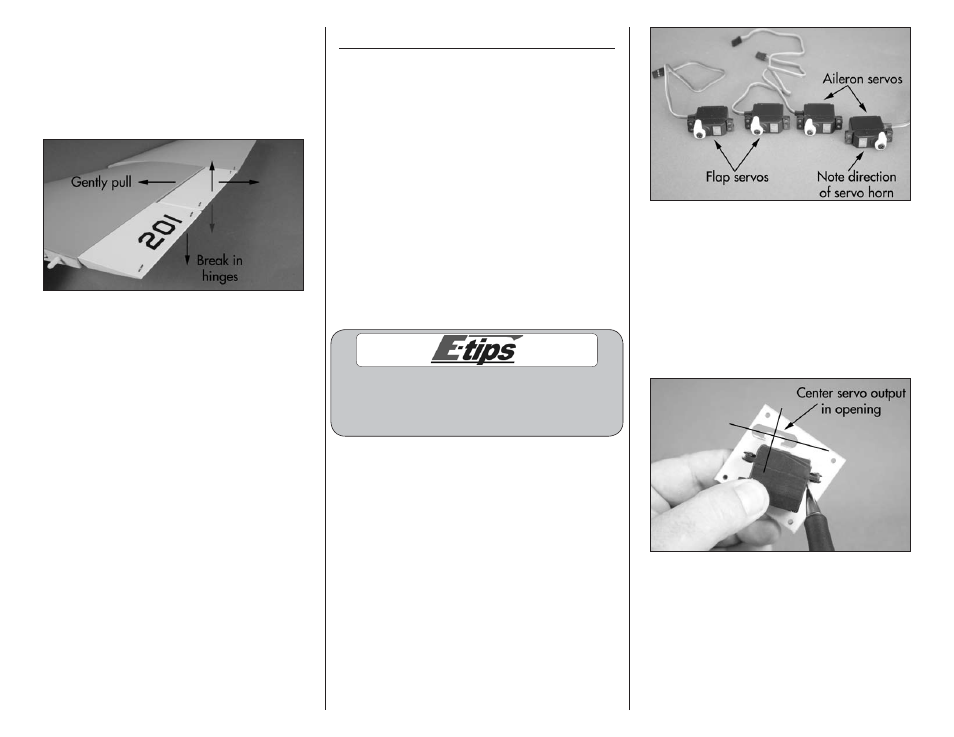

1. Prepare the aileron and flap servos by installing

the rubber grommets and brass eyelets as shown in

the radio or servo instructions. Use the shorter side

of a JR standard horn for the two aileron servos

and the longer side for the flap servos. Center the

aileron and flap servos using the radio system. Use

side cutters to remove any arms from the horn that

may interfere with the operation of the servo. Note

that one servo is set in the opposite orientation as

shown in the photo in the following column.

2. Use a felt-tipped pen to mark the flap and

aileron servo covers so they can be returned to

their correct locations, then remove the covers from

the wing. Set the flap cover aside. Use a pencil

to mark the centerlines for the servo output on the

cover. Position the servo on the cover so the center

of the servo horn is centered in the opening using

the lines drawn on the cover. Use a pencil to mark

the locations for the servo mounting blocks on the

servo cover.