0 service instructions – Watts Autotrol Magnum (CV+ Series) User Manual

Page 56

52

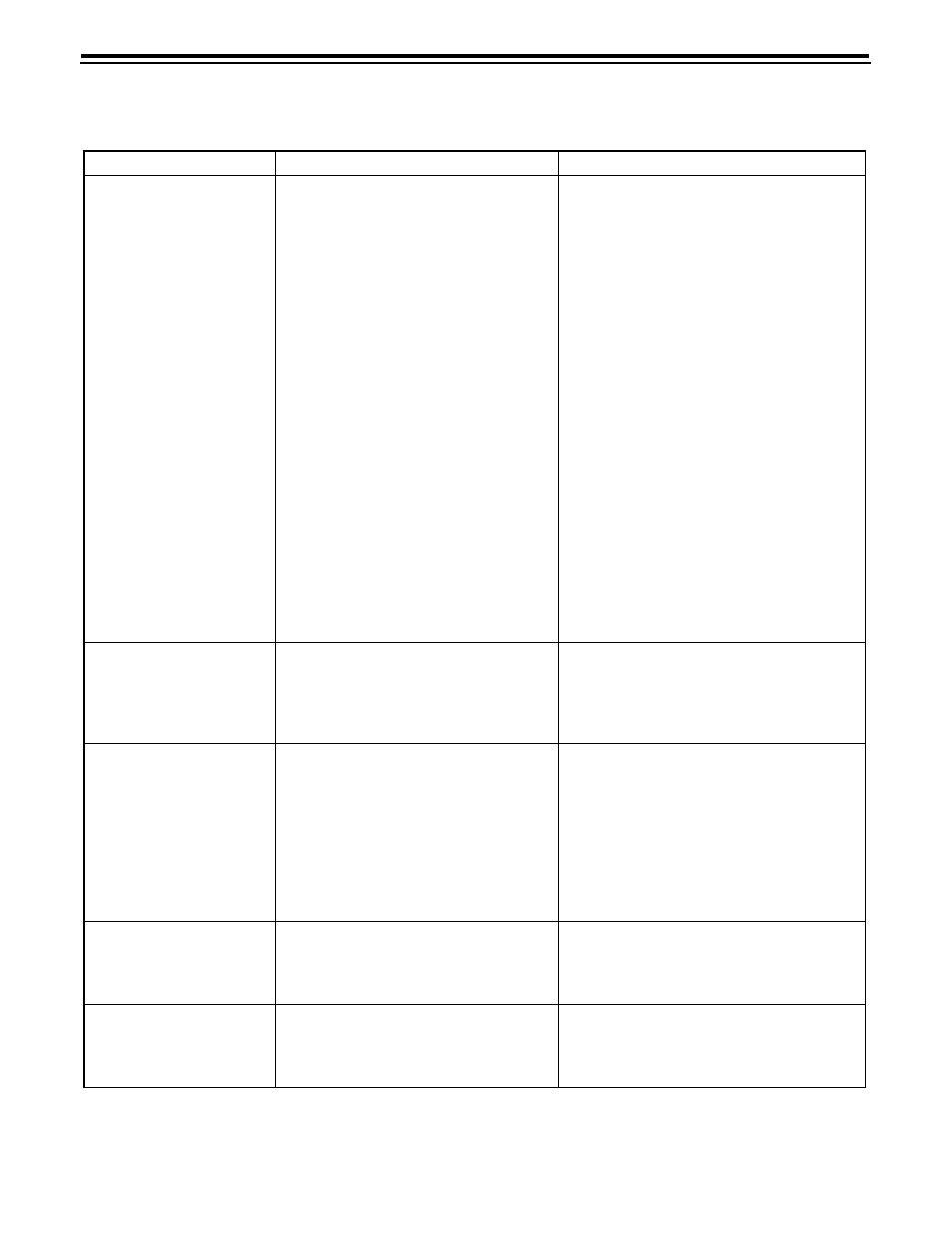

9.0 Service Instructions

Symptom

Possible Cause

Solution

1. Water conditioner fails to

regenerate.

No soft water.

a. Power supply to Magnum control

has been interrupted.

b. Water pressure lost.

c. For 942 series control, day pins are

not pushed in.

d. For 962 series control, improper or

no initial programming.

e. For 952 series control, no start of

regeneration signal received or

length of signal is insufficient.

f.

Defective control.

g. No salt in brine tank.

h. Manual bypass valve is open.

i.

For 962 series control, turbine meter

is clogged or restricted.

j.

Leak at riser pipe seal.

k. Insufficient brine.

l.

Plugged injector or injector screen.

a. Determine reason for power interruption

and correct.Reset time of day.

b. Restore water pressure.

c. Push day pins in for desired

regeneration days.

d. Check programming values in 962

control and correct as needed.

e. Test source signal to ensure positive

closure and length of signal. A minimum

signal length of 3 minutes is required.

f.

Replace control assembly.

g. Add salt and regenerate.

h. Close manual bypass valve.

i.

Inspect turbine meter assembly, clean

or replace.

j.

Insure that riser pipe is properly sealed

at tank adapter o-ring. Inspect pipe for

cracks.

k. Check refill control and clean if

necessary. Check control settings.

Check flow rate capabilities of safety

float and air check assembly.

l.

Inspect and clean injector and/or injector

screen.

2. No Brine Draw.

a. Plugged injector or injector screen.

b. Insufficient water pressure.

c. Obstructed drain line.

a. Inspect and clean injector and/or injector

screen.

b. Increase water pressure above 25 psig

(172 kPa) minimum.

c. Remove obstruction.

3. Insufficient brine draw.

a. Partially clogged injector or injector

screen.

b. Restricted flow rate in brine line.

c. Insufficient water pressure.

d. Excessive back pressure on injector

due to elevated drain line.

e. Partially restricted drain line.

a. Inspect and clean injector and/or injector

screen assembly.

b. Check flow rate capabilities of the safety

float/aircheck assembly.

c. Increase water pressure above 25 psig

(172kPa) minimum.

d. Reduce drain line elevation to height of

valve.

e. Remove restriction.

4. Insufficient Refill to Brine

Tank.

a. Restricted flow rate in brine line.

b. P6 (Refill) value incorrectly set.

c. P7 (Brine Draw) value incorrectly

set.

a. Check flow rate capabilities of the safety

float/aircheck assembly.

b. Reprogram P6.

c. Reprogram P7.

5. Excessive Water in Brine

Tank.

a. Plugged drain line flow control.

b. Plugged injector and/or injector

screen.

c. Incorrect refill control.

a. Clean flow control.

b. Inspect and clean injector and/or

screen.

c. Install correct control.