0 general installation information – Watts Autotrol Magnum (CV+ Series) User Manual

Page 14

10

3.0 General Installation Information

Please review the following items thoroughly to ensure

an efficient and safe installation of the water treatment

system. Page 12 shows typical installation line

drawings for the Magnum valves.

Operating Conditions -

A minimum dynamic

operating water pressure of 25 psig (172 kPa) is

required for the Magnum control valve to

operate properly.

Water pressure is not to exceed

125 psig (862 kPa). In Canada, water pressure is not to

exceed 100 psig (688 kPa). Water temperature is not to

exceed 100

o

F (36

o

C). Do not subject the valve to

freezing conditions.

Space Requirements - Allow adequate space for the

water treatment system and associated piping. The

General Specifications section (pages 7-9) provides

the overall dimensions of the control valve as well as

the dimensional reference information for each of the

connection ports. A minimum of 4 1/2 inches (11.5 cm)

front and rear clearance is required for cartridge

assembly and removal.

Plumbing - Always follow good plumbing practices

and conform to local codes. Check existing pipes for

lime and/or iron buildup. Replace piping if heavy

buildup exists and initiate the proper treatment to

prevent additional occurrences. Locate the equipment

close to a drain that is capable of handling the

maximum drain flow rate during backwash.

Flexible Connectors - Some tanks expand and

contract over the acceptable range of operating water

pressures of the Magnum control valve. The use of

flexible connectors is recommended on polywound or

fiberglass tank installations of 24-inch (60.96-cm)

diameter and larger. Follow the tank manufacturer’s

instructions for more information.

Inlet and Outlet Piping - Inlet and outlet plumbing

should be adequately supported to avoid excessive

loads on the valve. Install a manual bypass system to

provide for occasions when the water conditioner must

be bypassed for servicing.

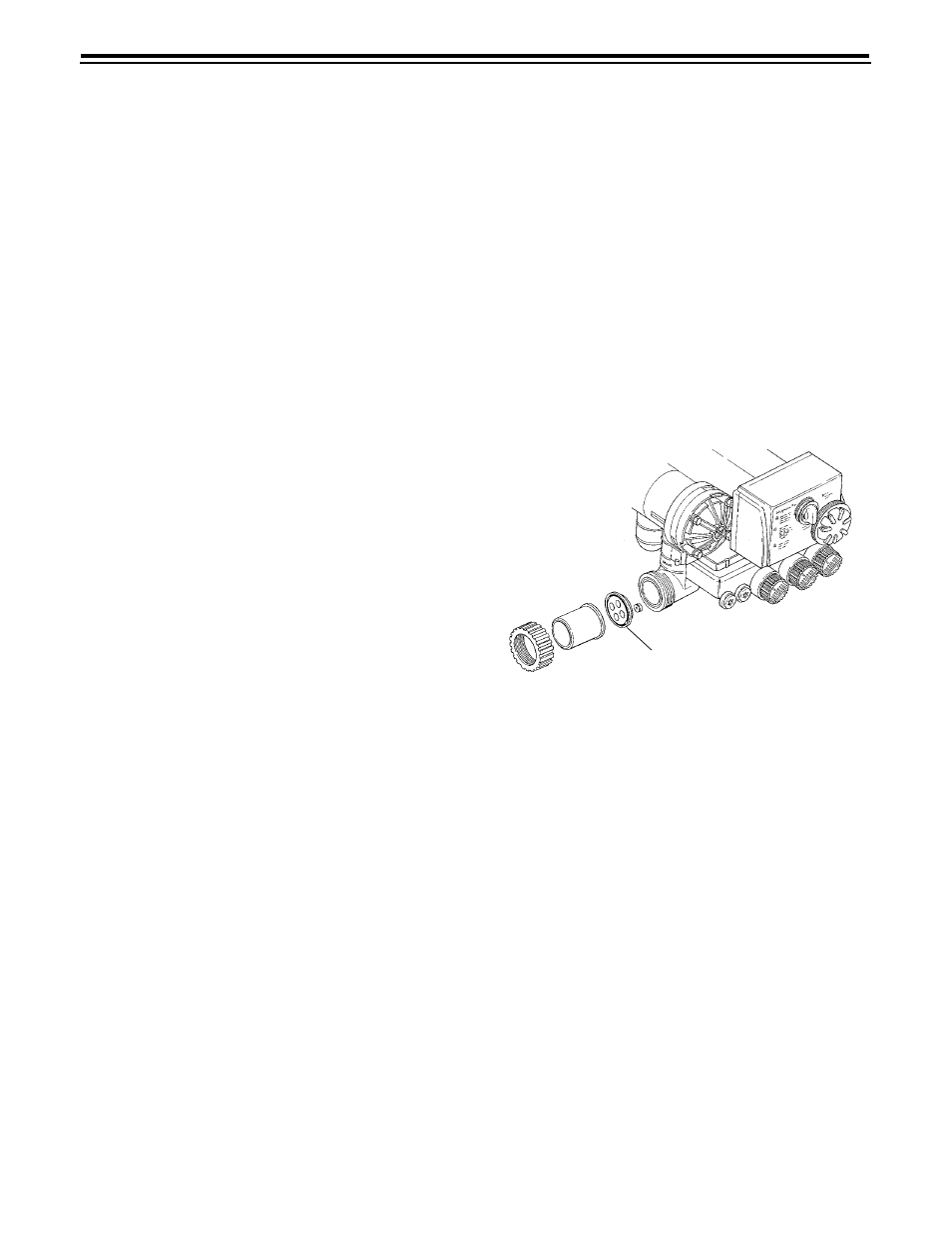

Drain LIne Piping - To prevent mineral loss during

backwash, and to ensure proper operation of the

Magnum Cv Series control valve, A DRAIN LINE

FLOW CONTROL must be plumbed into the drain line

prior to placing the valve in the service mode. Flow

controls from 5 to 40 gpm (18.92 to 151.4 Lpm) are

available from GE Osmonics and can be easily installed

in the drain line (Figure 3.1). Flow controls greater than

40 gpm (151.4 Lpm) must be plumbed externally.

Selection of the proper drain line flow control will

depend on the tank size and media used for the

installation. See Table 10.3.

The following general drain line piping guidelines

should be observed:

•

1 inch (2.54 cm) or larger piping

•

Should not exceed 20 feet (6.1 m)

•

Should not be elevated higher than the control

valve

•

No shut-off valves should be installed in drain line

•

Minimal number of elbows and fittings should be

installed in drain line

•

Piping must be self-supporting

•

Install air gap to provide a siphon break

•

Flow control should be installed as close to the

Magnum Cv Series control valve as possible if an

external flow control is used.

Figure 3.1

Brining System - The Magnum control valve utilizes

timed water refill to add water to the salt tank. A refill

tube with check ball is required in the brine tank that will

not restrict the refill or brine draw flow rate capabilities

of the valve. Although not required, a separate brine

valve (safety float) system is recommended for use with

Magnum installations. Select a “High-Flow” brine valve

that will not restrict the refill or brine draw flow rate

capabilities of the valve. The “Performance Data and

Charts” section (Section 10.0) of this manual contains

flow rate information for various size injectors and refill

controllers.

Pilot Drain - During regeneration, a small amount of

water (200 ml or 1 cup) is discharged from the 1/4-inch

(6.3-mm) tube fitting on the back of the valve marked

DRAIN (Figure 3.2). To prevent this water from being

discharged to the floor, plumb this connection to a non-

pressurized drain or to the brine tank. Do not plug or

apply back pressure to the pilot drain at any time.

Crimping the pilot drain line or installing the line to go

up, which causes backpressure, will prevent the

diaphragm cartridges from shifting properly through

the cycles of regeneration or backwash.

Drain Line Flow Control Disk