Watts Autotrol Magnum (CV+ Series) User Manual

Page 34

30

•

Selectable Reserve Options (Demand Controls

Only) - To meet the conditioned water

requirements of the application, the 962 control

allows selection of one of two reserve types:

– Fixed Reserve - The reserve is fixed at a

progammable percentage (30% factory preset)

of the total softening capacity.

– Variable Reserve - The controller monitors the

daily water usage and at the programmed time

of regeneration, calculates the average water

used for each day of the week. The reserve

capacity is set to 120% of the average water

usage for the next day.

•

Delayed Regeneration on Twin-alternating

Systems - The twin-alternating system does not

use a reserve capacity. The service tank switches

when the softening capacity is exhausted.

Regeneration of the exhausted tank will occur at

the specified time of day when using the delayed

regeneration feature.

•

Immediate Regeneration on Twin and Triple

Parallel Systems - The twin and triple parallel

systems use a reserve capacity of “0” along with

immediate regeneration. Regeneration of an

exhausted tank in the system will occur

immediately after reaching its maximum capacity,

IF, there are no other tanks within the system

already regenerating.

Normal Display Modes

In the normal operating mode the Series 962 control

will alternate between Capacity Remaining (gallons or

m

3

) and Flow Rate (gallons per minute or m/hr). In the

event of power loss, the display will alternate between

Time of Day and Capacity Remaining once power

has been restored. The normal operating display mode

of the twin alternating system scrolls through three

displays. They are: Capacity Remaining of tank 1 in

gallons, Capacity Remaining of tank 2 in gallons, and

Flow Rate. If a power outage has occurred, the flow

rate display will change to Time of Day. In both cases

the control will remain in Power Loss display mode

until the Time of Day is reset or until any button is

pressed. (Electronic Time Clock displays Time of Day

only).

Programming the Series 962 Controls

This section contains common aspects of

programming the 962, 962F, and 962M controls and

retrieving historical operating data. The 962S control is

a secondary unit that always works in conjunction with

the 962M main control for twin alternating tank

applications. The operating values for the 962S are the

same as the operating values in the 962M control. An

adhesive installation label is provided with each 962,

962F, and 962M control. It is recommended that this be

filled out with programming parameters on start-up and

placed on the inside of the cam cover.

Factory Default Values - The control is shipped from

the factory with a default value for Salt Amount of 10 lb.

(4 kg for metric units). Capacity, Hardness, Refill and

Brine Draw values are set to 0 and must be changed

to appropriate values before the control will

operate. “Err 4” will be displayed until a valid

number is entered for each of these items. Program

variable P12 is preset at the factory to define the U.S.

units of measure for North American application or

metric units of measure for application outside North

America.

Program Levels - The Series 962 controls have been

designed to facilitate different levels of programming

requirements. Level I includes program variables that

are frequently referenced by users, operators,

installers, and service personnel, and is accessible

without the requirement of codes. Level II includes

variables that are most typically used at the time of

installation and initial setup and is accessible with

special access codes. Level III locations are used

primarily for accessing operating history information.

Level III parameters also require access codes.

Programming levels are further defined in Section 6

(page 34).

Table I on page 34 lists the Level I program values for

the 962, 962F, 962TC, 962FTC and 962M controls.

Tables IIA through IIE, on pages 35-41, list the Level II

program values for all 962 series controls.

Program Values and Locations - The P values that

are programmed into the Series 962 controls are listed

in the Level I and Level II tables.

Locating a Program Value - To locate and display a P

value in Level I press the UP [

↑ ] or DOWN [↓] arrow

button until the desired value is displayed.

To locate and display a P value in Level II,

simultaneously press the UP [

↑ ] and DOWN [↓] arrow

buttons for 3 seconds to gain access. Press the UP [

↑ ]

or DOWN [

↓] arrow buttons until the desired location is

displayed. Press LEFT [

←] to display a value in P

locations.

To locate and display an L value in Level III,

simultaneously press the LEFT [

←] and UP [↑ ] arrow

buttons for 3 seconds to gain access and the press the

UP [

↑ ] or DOWN [↓] arrows buttons until the desired

location is displayed. Press LEFT [

←] to display value in

the L location.

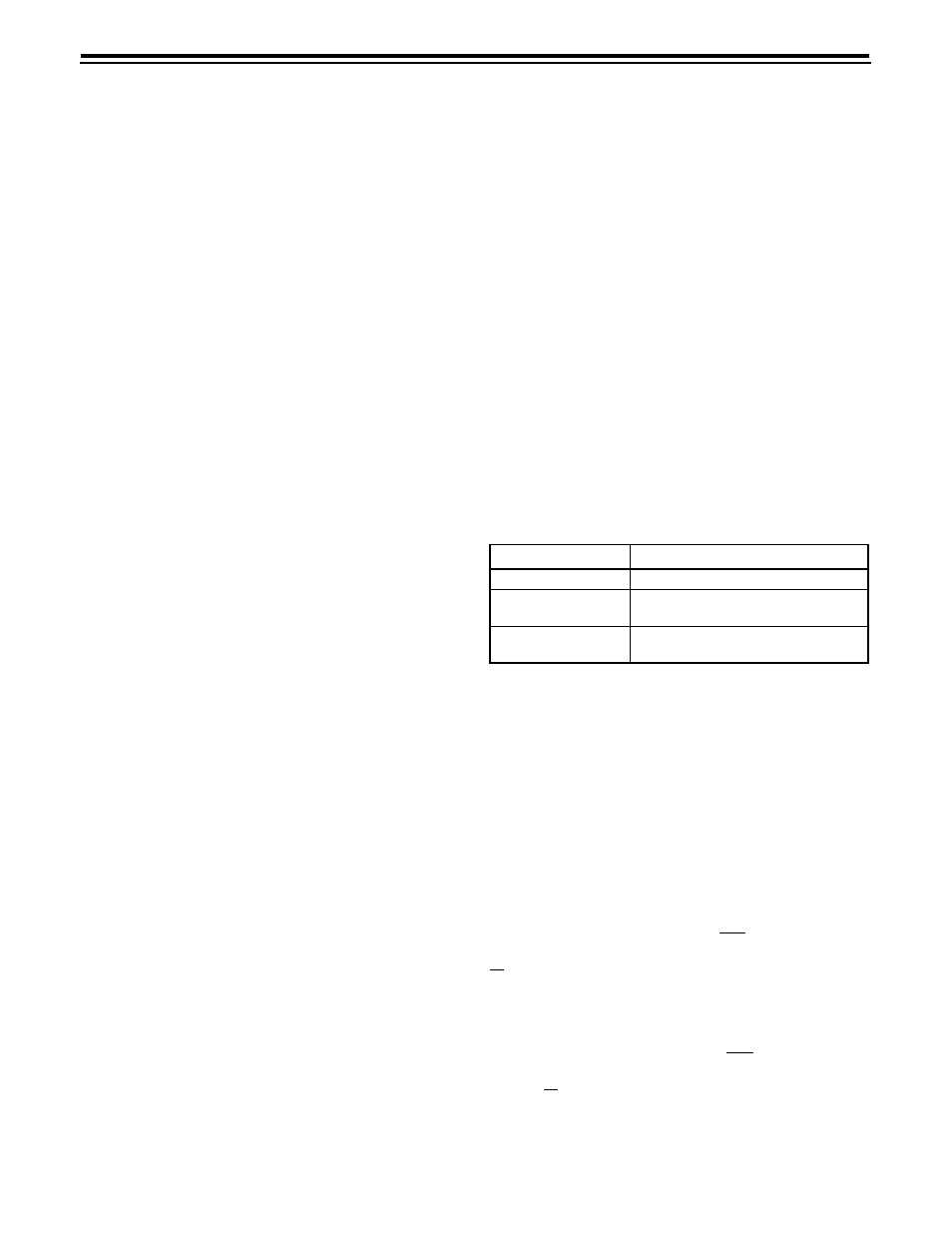

Levels

Access Code

I

None required

II

Press and hold the

↑ ↓

for approximately

3 seconds

III

Press and hold the

← ↑

arrow buttons for

approximately 3 seconds