6 troubleshooting, 7 technical specifications – Metrohm 940 Professional IC Vario ONE/SeS/PP/Prep 3 User Manual

Page 115

■■■■■■■■■■■■■■■■■■■■■■

6 Troubleshooting

940 Professional IC Vario ONE/SeS/PP/Prep 3 (2.940.1530)

■■■■■■■■

105

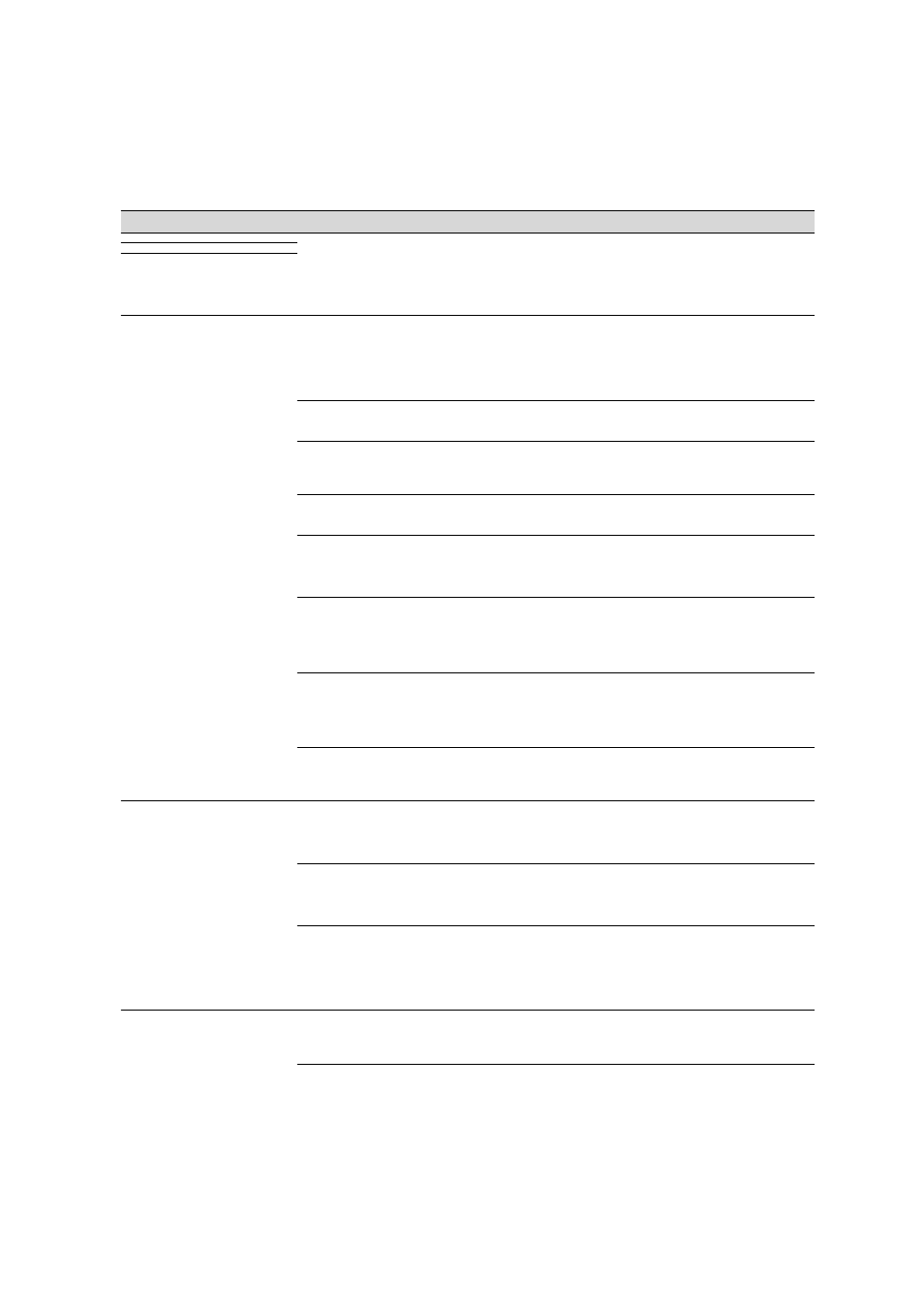

6 Troubleshooting

Problem

Cause

Remedy

Marked drop in

pressure.

Leak in the system.

Check all capillary connections and seal leaks,

if necessary (see Chapter 3.2, page 14).

The baseline has a

large amount of

noise.

The eluent is not suffi-

ciently degassed.

Ensure that the connectors for the eluent

degasser are firmly connected (see Chapter

5.6, page 70).

The eluent path has a leak.

Check the eluent path and fix the leak.

High-pressure pump – Con-

taminated pump valves.

Clean pump valves (see Chapter 5.8, page 72).

The eluent path is blocked.

Check the eluent path and fix the blockage.

High-pressure pump –

Defective piston seals.

Replace the piston seals (see Chapter 5.8,

page 72).

MCS – The

CO

2

adsorber cartridge is

depleted.

Replace the CO

2

adsorber cartridge (see Chap-

The pulsation absorber is

not connected or is defec-

tive.

Connect (see Chapter 3.11, page 27) or

replace the pulsation absorber.

MCS – The vacuum pump is

defective.

Contact Metrohm Service.

The baseline is drift-

ing.

Thermal equilibrium is not

yet attained.

Condition the instrument with the column

thermostat enabled until the baseline is stable .

Leak in the system.

Check all capillary connections and seal leaks,

if necessary (see Chapter 3.2, page 14).

The organic solvent in the

eluent is evaporating.

■

Check the eluent bottle cap (see Chapter

3.7, page 22).

■

Constantly stir the eluent.

The pressure in the

system markedly

increases.

The inline filter

(6.2821.120) is blocked.

Replace the filter (6.2821.130) .

Suppressor blocked.

■