2 theory of operation – Metrohm 750 Autosampler User Manual

Page 5

1 Introduction

750 Autosampler

2

1.2

Theory of operation

Displacement principle

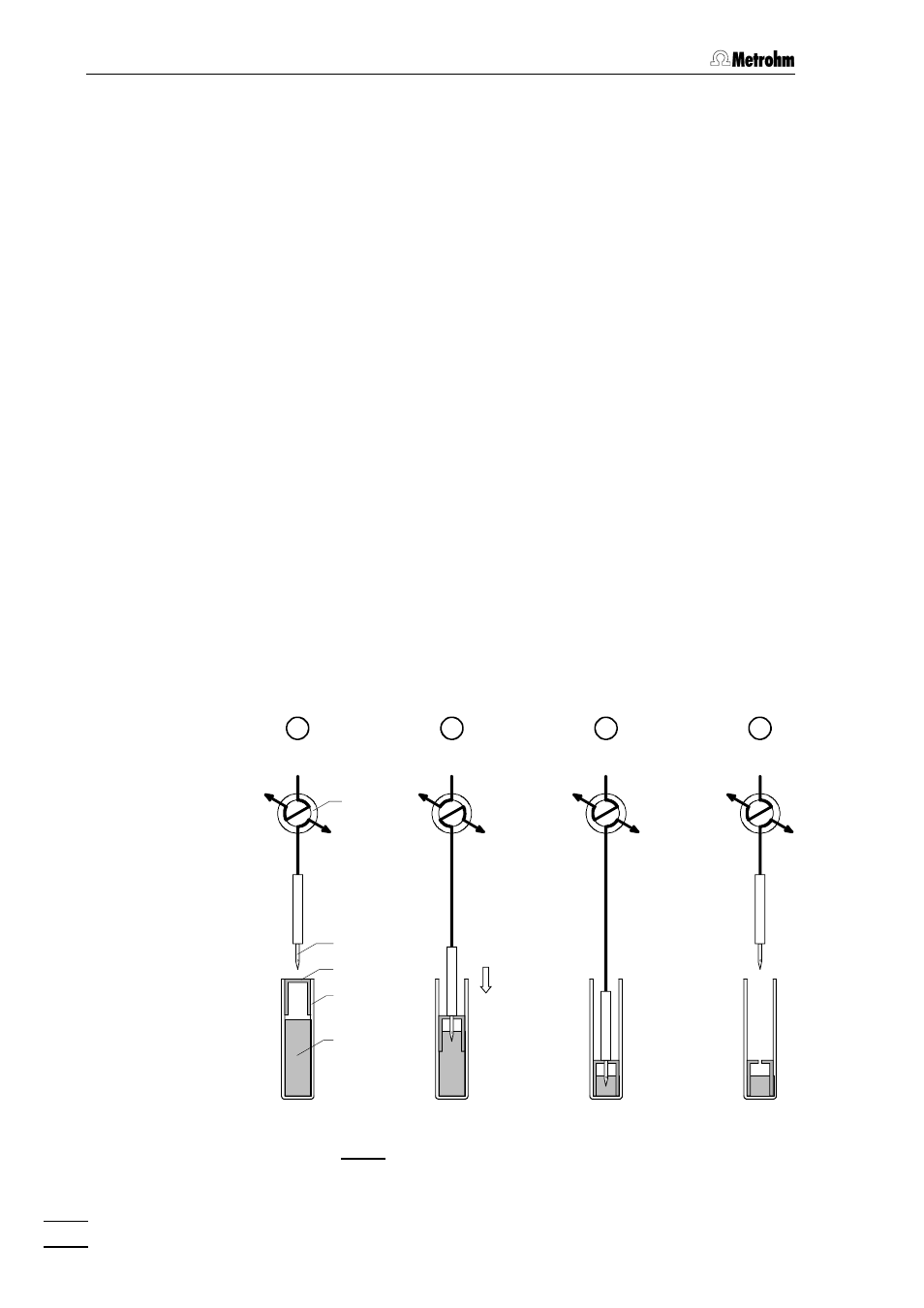

The 750 Autosampler operates using the positive displacement princi-

ple of sample transfer. This sample transfer process into the sample

loop of the 733 IC Separation Center is illustrated in Fig. 2. When an in-

jection is initiated, the hollow transfer needle 55 descends into the vial.

The needle tip punctures the polyethylene cap of the sample vial. The

opening into the needle is located on the side to minimize plugging by

cap material as the cap is punctured. The needle continues downward

until the pushrod contacts the area around the puncture in the cap

which forces the cap down into the vial. The piston action of the cap

pressurizes the sample and forces it up through the needle and the

transfer tubing 88 that is connected to the needle. From the transfer

tubing, the sample flows through the injection valve and sample loop

with the excess passing on through the waste tube to a waste con-

tainer.

Rinsing by air bubbles

The air bubble (minimum 150

µ

L), which is always present at the top of

a properly filled and capped vial, precedes the sample stream through

the plumbing. The bubble disrupts the laminar flow of the fluid in the

tubing while pushing out the previous sample and solvent. This effect,

in addition to the large excess volume of sample, helps to minimize

sample carryover.

RUN

FILL/LOAD

INJECT

RUN

A

B

C

D

Fig. 2: Positive displacement sample injection

Column

Waste

Eluent

Sample

Needle

Cap

Sample vial

Valve