4 malfunctions – maintenance, Handling dialysis membranes, Care of the unit – Metrohm 754 Dialysis Unit User Manual

Page 32: Maintenance by metrohm service, Shutdown, Replacing the pump tubing, Replacing the dialysis membrane, 4malfunctions – maintenance, 1 malfunctions and their rectification

4.1 Malfunctions and their rectification

754 Dialysis Unit

29

4

Malfunctions – Maintenance

4.1

Malfunctions and their rectification

If difficulties appear with the IC system during analysis, their cause are

best investigated in the order separating column

→

→ pump →

→ eluent

→

→ IC system. An overview of possible malfunctions, their causes and

remedies can be found in the instruction manuals of the 732/733 IC

System (section 5.3.2). In addition to these general malfunctions the

table below contains others which might arise as a result of the opera-

tion of the 754 Dialysis Unit.

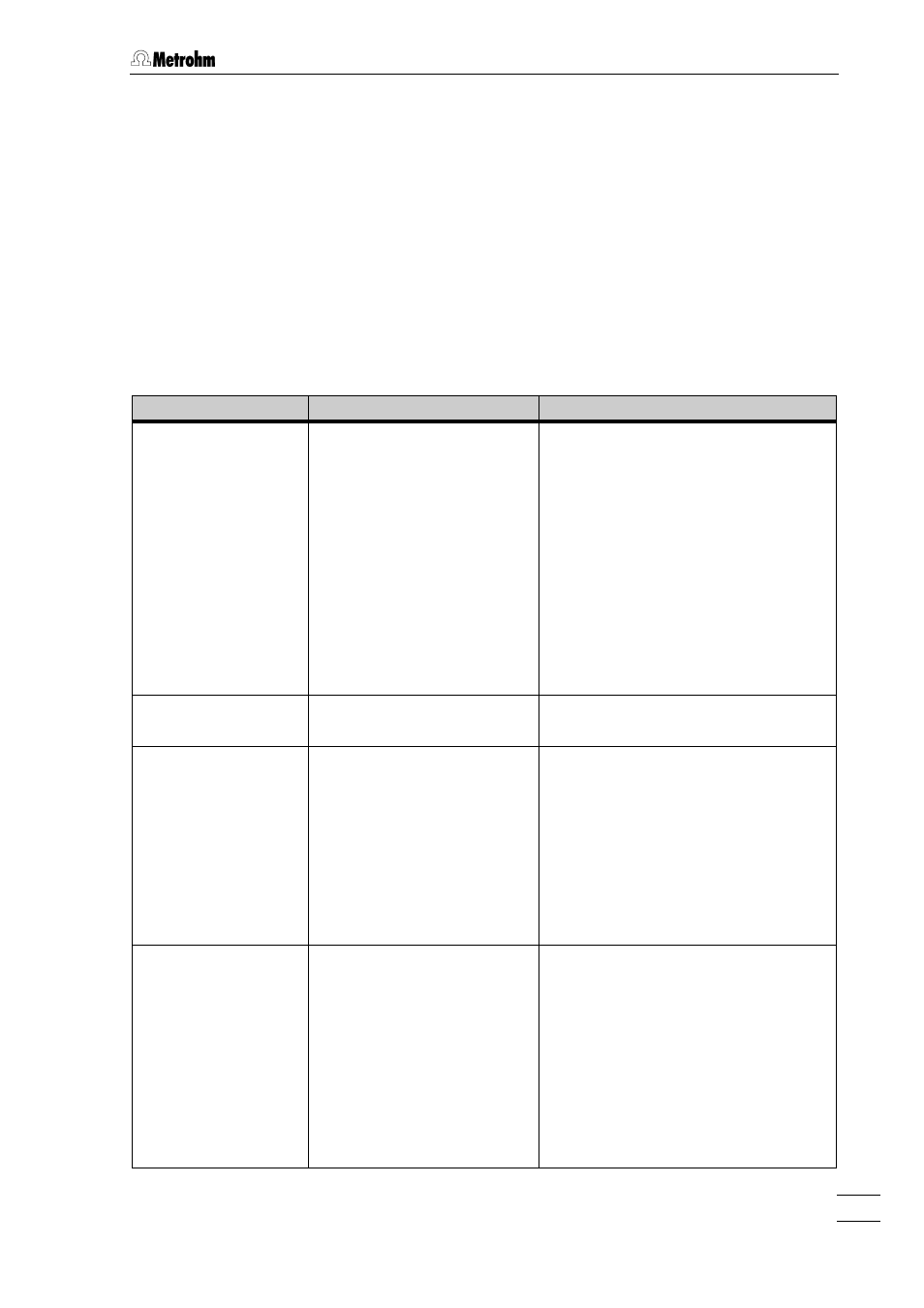

Malfunction

Possible causes

Rectification

Insufficient or non-

existing flow rate at

754 Dialysis Unit

•

Contact pressure too low

•

Pump tubing faulty

•

Inlets to dialysis cell blocked

•

Sample tubing blocked by

particles that are too large

•

Bacterial growth in the sample

channel and dialysis cell

•

Overly narrow PTFE tubings due

to excessive tightening of the

compression fittings

•

Set contact pressure correctly with contact

pressure lever (see section 2.3.3).

•

Replace pump tubing

(see section 4.2.5).

•

Replace the dialysis membrane and clean

the cell (see section 4.2.6).

•

Replace blocked tubing; always centrifuge

samples (see section 3.3.7).

•

Periodically replace tubings

26

26, 30

30, 33

33 and

45

45 for the sample channel; replace the

dialysis membrane

•

Replace tubings.

Leakage

•

Leaking compression fittings

•

Tighten the compression fittings or replace

if necessary.

Air bubbles in pump

circuit

•

Suction tubing is not immersed

•

Leaking compression fittings

•

Acceptor solution insufficiently

degassed

•

Standing air bubbles

•

Ensure suction tubing is fully immersed in

the acceptor or sample solution.

•

Tighten the compression fittings or replace

if necessary.

•

Re-degas the acceptor solution.

•

Small air bubbles are not a problem. If big

air bubbles occur, rinse the sample chan-

nel with degassed acceptor solution (open

outlet briefly if need be).

Insufficient yield from

dialysis

•

Transfer time incorrectly set

•

Dialysis time too short (e.g.

when concentration is too low)

•

Dried out or damaged dialysis

membrane

•

Deposits on the dialysis mem-

brane, recognizable from dis-

colouring at the sample inlet

•

Unsuitable dialysis membrane

•

Check optimum transfer time, especially

after each change of membrane or tubing

(see section 3.3.4).

•

Check optimum dialysis time (see section

3.3.5).

•

Replace dialysis membrane

(see section 4.2.6).

•

Replace dialysis membrane

(see section 4.2.6).

•

Use different dialysis membrane.