Rockwell Automation FlexPak 3000 DC Drive Version 4.3 User Manual

Page 68

A-2

FlexPak 3000 DC Drive Hardware Reference Version 4.3

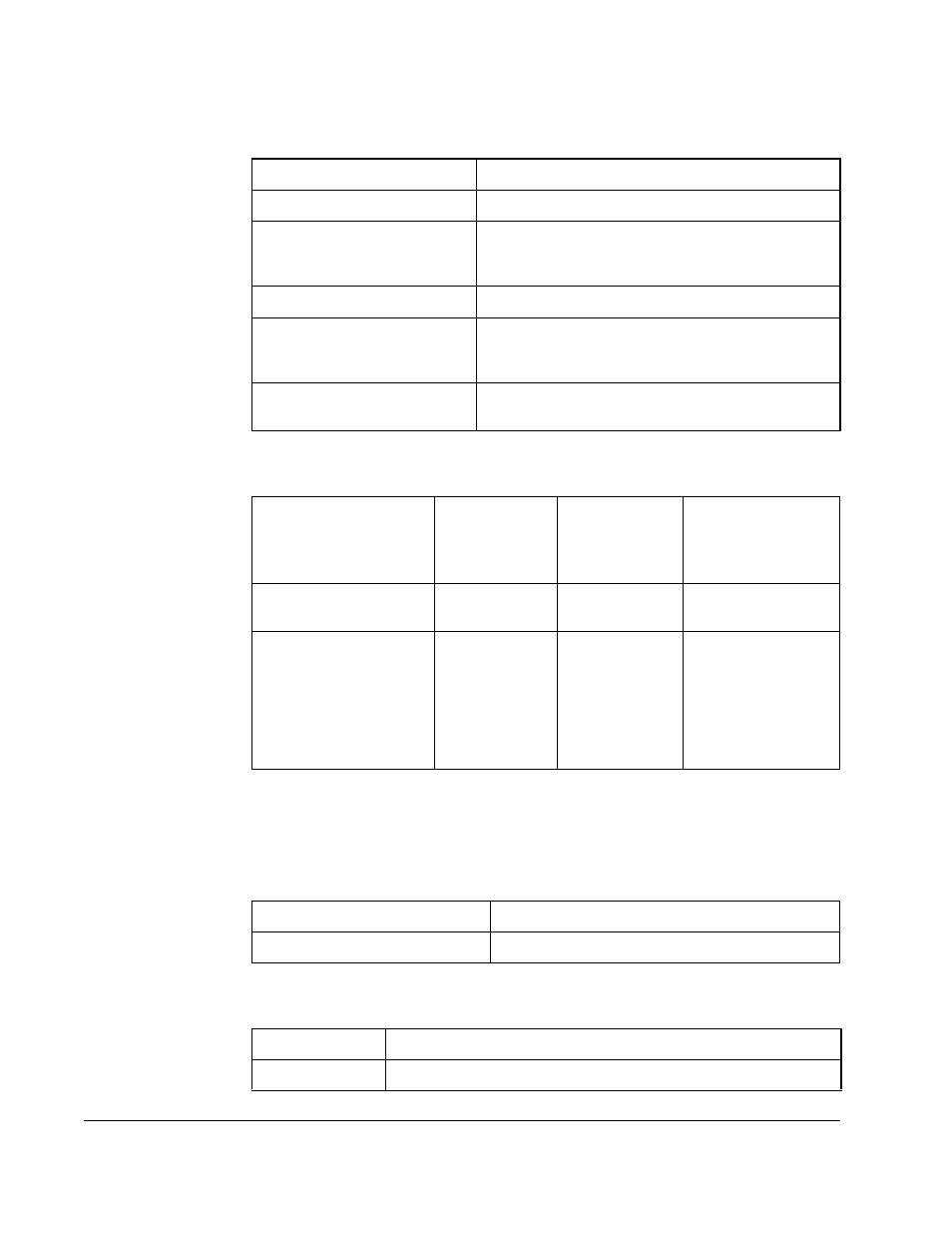

Table A.2 – Service Conditions

Service Factor

1.0 continuous

Overload Capacity

150% of full load for 1 minute

Motor Overload Function

Drive uses an internal inverse time thermal

overload based on motor amp measurement and

full load motor rated amps parameter entry.

Minimum Load

5% of rated load

Ambient Temperature:

Chassis (inside cabinet)

Cabinet (external)

0° to 55°C (32° to 131°F) maximum

0° to 40°C (32° to 104°F) maximum

Altitude: Chassis and Cabinet

3300 feet above sea level (Derate 3% for every

1000 ft above 3300 ft up to 10,000 ft)

Table A.3 – Drive Regulation

Regulation

Arrangement

Speed

Change with

95% Load

Change

Speed

Change from

All Other

Variables

Kit

Model Number

Armature Voltage w/ IR

Compensation

2-3%

15%

Not applicable

Closed Loop

w/ RE-045 tach

1

w/ 5PY tach

2

w/ RD-120-1 tach

3

w/ RD-120-2 tach

3

w/ RD-62 tach

3

1

Optional AC Tachometer Feedback kit required (see instruction manual D2-3297)

2

Standard DC Tachometer (see section 2.8.6 if used)

3

Optional Pulse Encoder Feedback kit required (see instruction manual D2-3302)

1%

1%

0.01%

0.01%

0.01%

2%

2%

0.01%

0.01%

0.01%

907FK0301

907FK011

907FK011

907FK011

Table A.4 – Speed Range

Operator’s Speed Adjustment

0 to rated speed

Specification Speed Range

100:1 based on top speed and tachometer

Table A.5 – Drive Efficiency

Drive Only

98.6% (rated load and speed)

Drive and Motor

85% typical (depends on motor operating speed and frame size)