Rockwell Automation T6200 Compressor Anti-Surge and Capacity Controller User Manual

Page 157

Configuration

8-37

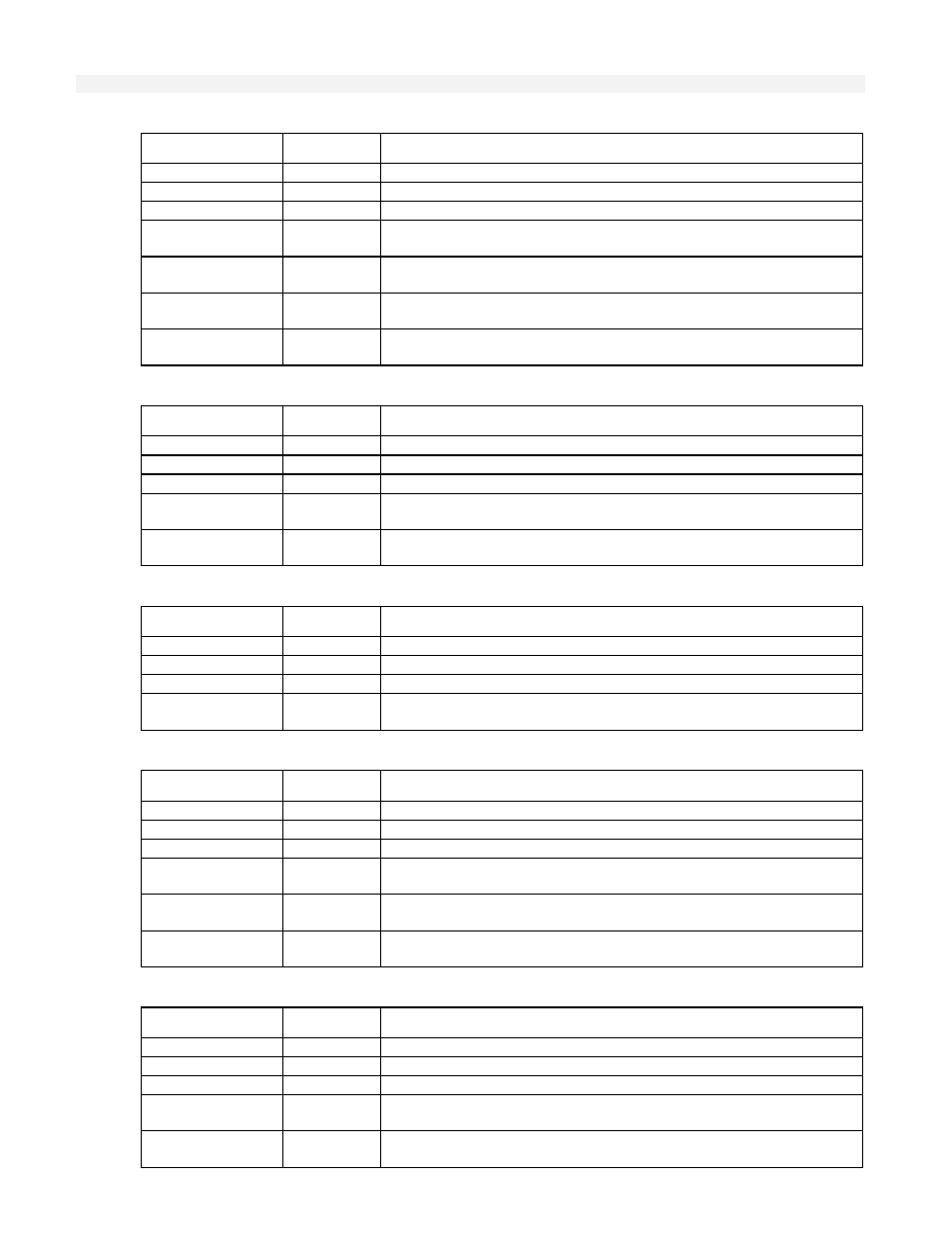

Table T5. - Anti-Surge and Incipient Surge PID Tuning Settings

Name Init.

Value

Description

Bias_Mgn

% Bias Addition to SCL (Surge Control Line) – Enter from HMI

AS_V_SluC

AS Valve (Recycle/BV) Slew Closing Rate (typically set at 1% per sec)

AS_G_BP1

Adapt Gain Break Point (< SCL; Slope m1 gain increase if below BP1)

AS_CGAIN

AS_PID.Tuning_Proportional (Gain is typically set at 0.20)

AS_CRESET

AS_PID.Tuning_Integral (typically preset at 20 repeats/min)

IS_CGAIN

IS_PID.Tuning_Proportional (Gain is typically set at 0.20)

IS_CRESET

IS_PID.Tuning_Integral (typically preset at 15 repeats/min)

Table T6. - Decoupling and Pressure Rate Constraint Settings

Name Init.

Value

Description

DC_LeadT

Decoupling Lead Time in Seconds

DC_Ampl

Decoupling Signal Amplitude (Recycle/Blowoff Valve % change, 0-1)

DC_Rate

Decoupling Signal Rate (Recycle/Blowoff Valve Rate of change)

Ps_RC_Set

Suction Pressure Rate Constraint (units/sec); Alt. Pd, PR, h constraint

Table T7. - Loadshare Efficiency Settings

Name Init.

Value

Description

LSE_SP_Rate

Efficiency Setpoint Ramp Rate Setting

LSE_SPHILM

Efficiency Setpoint High Limit

LSE_SPLOLM

Efficiency Setpoint Low Limit

Table T8. - Capacity Control Settings

Name Init.

Value

Description

Cap_CGAIN

Cap_PID.Tuning_Proportional (Gain is typically set at 0.40)

Cap_CRESET

Cap_PID.Tuning_Integral (typically preset at 10 repeats/min)

Cap_D_Hi

Cap PID Deviation Alarm High (eng units)

Cap_D_Lo

Cap PID Deviation Alarm Low (eng units)

LU_Lch_P

Initialization SP Value (Ps, Pd, PR) after LineUp Latch Option

Table T9. - Other Loops – Turbine, OL, SV, etc. - Control Settings

Name Init.

Value

Description