Rockwell Automation T6200 Compressor Anti-Surge and Capacity Controller User Manual

Page 155

Configuration

8-35

T6200 – Variable, Alarm & Tuning Settings

Enter/verify all settings & make sure that they comply with the requirements of your application.

Ensure that these settings are defined in the Straton for MICON FB Program and Variable List.

Setting apply to each compression stage!

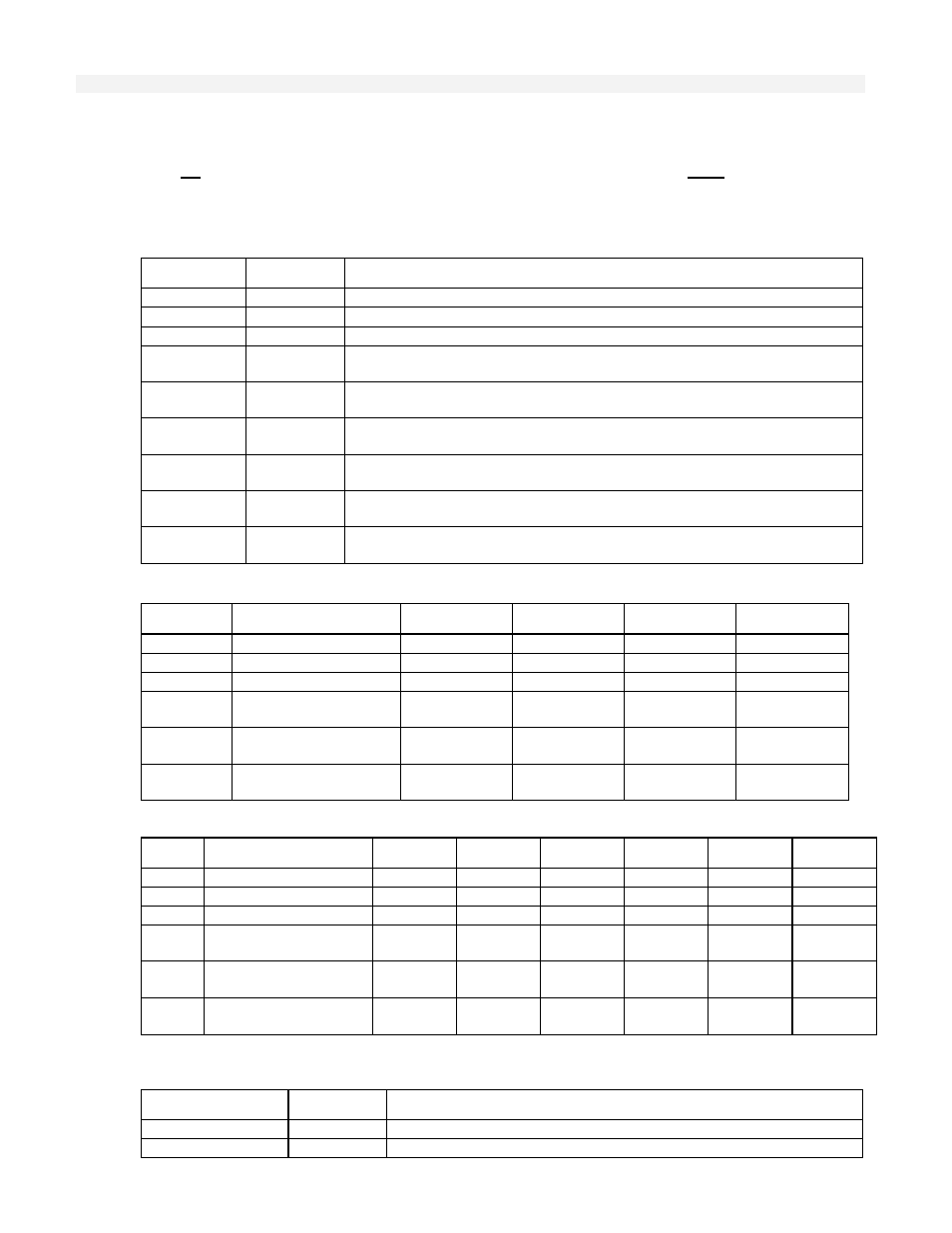

Table T1. - Anti-Surge Variables – Initial Settings

Name Init.

Value

Description

K

Co-Efficient=

(R2/R1)*(Za/Zs)*(1/A**2) – Enter K value from M/C Tool

M_pr_FBset

M_pr Fallback Value (k-1/K*Pe), FB on Ps|Ts Fail – Verify with M/C Tool

SAFEh

SAFE ‘h’ Fallback Value if Suction Press XTMR fails – Verify with M/C Tool

A

Flow Co-Efficient (for Q display) – from M/C Tool

Zs

Inlet Compressibility (indication, used in K and Q calculations)

Zd

Discharge Compressibility (indication)

MW_Set

Molecular Weight Entry (for display only, not used in surge calculations)

R1

R1 Gas Constant for Q and K calculations (EU=10.73, MU= 0.08478)

R2

R2 Gas Constant for Hp and K calculations (EU= 1545, MU= 847.80)

Table T2. - Anti-Surge and Incipient Surge Fallback (FB) Alarm Values and Limits

Name Description

Value_Max

Limit_Max

Limit_Min

Value_Min

Ps

Suction

Pressure

Pd

Discharge

Pressure

Ts

Suction Temp

Td

Discharge Temp

h

Flow ‘h’ (Suct or

Disch)

Incip_SG

SurgeGard Input

Table T3. - Anti-Surge and Incipient Surge Process (XM) Alarm Limits for Compressor

Name Description Max HH H

L LL Min

Ps

Suction Pressure

Pd

Discharge Pressure

Ts

Suction Temp

Td

Discharge Temp

h

Flow ‘h’ (Suct or

Disch)

Incip_

SurgeGard Input

Recommended Alarm Levels: Ps=High-Low-Min; Pd=High-Low; Ts=High; Td=High; h=Low-Min; Incip_SG= High

Table T4. - Anti-Surge Op Tracking and Surge Spike Settings

Name Init.

Value

Description

SP_Hv_Thr

Setpoint Hover (Op Tracking) Enable % above SCL-Surge Control Line

SP_Hv_Mgn

Setpoint Hover (Op Tracking) Margin (track % to Op Point)