Rockwell Automation 8520 9/Series Hardware TAB 5 User Manual

Page 29

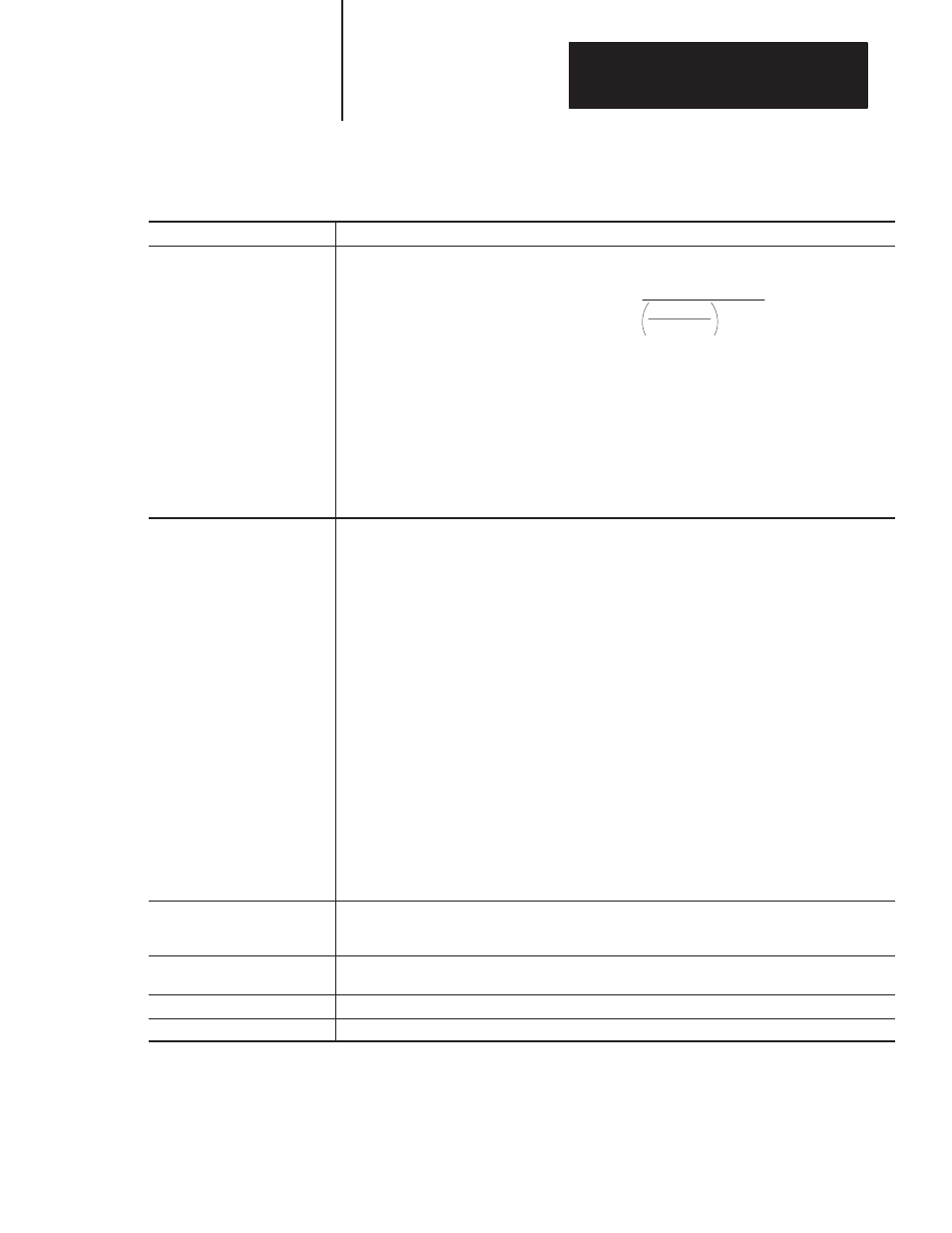

Maximum Encoder Channel Frequency =

Clock

360

x 1.15

90–Eq

Section 5A

9/440 Resolver–based CNC/Drive System

5A-27

Table 5A.A

Encoder Specifications

Item

Specification

Maximum Encoder Channel

Frequency (ECF)

Use the following equation to determine the maximum channel frequency

Where:

Clock – is the Control’s Feedback Clock Frequency:

5 x 10

6

– for 9/230, 9/440, and three axis servo cards.

2.3 x 10

7

– for 9/260 or 9/290 systems using a four axis servo card

E

Q

= Quadrature Error in Degrees

1.15 = Our minimum recommended safety factor

As long as the actual feedback channel frequency does not exceed the maximum channel frequency

calculated above, the servo module should process the feedback data without a quadrature fault.

Maximum Axis Speed

Use the following equation to determine the maximum axis speed. Note that this equation does not take

into consideration any mechanical deficiencies in the encoder or motor. It is only concerned with the

9/Series capability of receiving feedback. Refer to the manufactures specs for encoder and motor

hardware RPM limitations.

(ECF x 60)

---------------- = Maximum Axis Speed

(E) (N) (P)

Where:

Max Axis Speed = Maximum Axis Speed based on encoder feedback (inches or millimeters per minute)

ECF = Maximum encoder channel frequency the control may receive in units of cycles/sec.

E = the number of encoder lines between markers for your encoder

N = the ratio of encoder turns to ballscrew turns

P = the ballscrew pitch (turns per inch or turns per millimeter. For rotary axes, substitute the appropriate

gear ration for N and P in the equation above to solve for a max RPM in revolutions per minute.

If the maximum axis speed resulting from this equation is less than you would like, you may need to

sacrifice some axis resolution by selecting an encoder with fewer lines between markers.

Input Signal

Encoder feedback must be differential format with 5V compatible output signals, single-ended

open-collector outputs are not supported, i.e., channels A, B, and Z must have source and sink current

capability, 8830 line driver outputs or equivalent.

Current Drawn from Encoder by

Servo Module

7mA maximum; 44mA peak

Marker Channel

Narrow marker (gated) or Wide marker (ungated) type markers are supported

Encoder Cable Length

Refer to 9/Series Integration and Maintenance Manual for details on cabling