Wiring motor power, thermals, and brakes – Rockwell Automation 8520 9/Series Hardware TAB 5 User Manual

Page 20

1

2

3

4

5

6

7

8

9

10

Section 5A

9/440 Resolver–based CNC/Drive System

5A-18

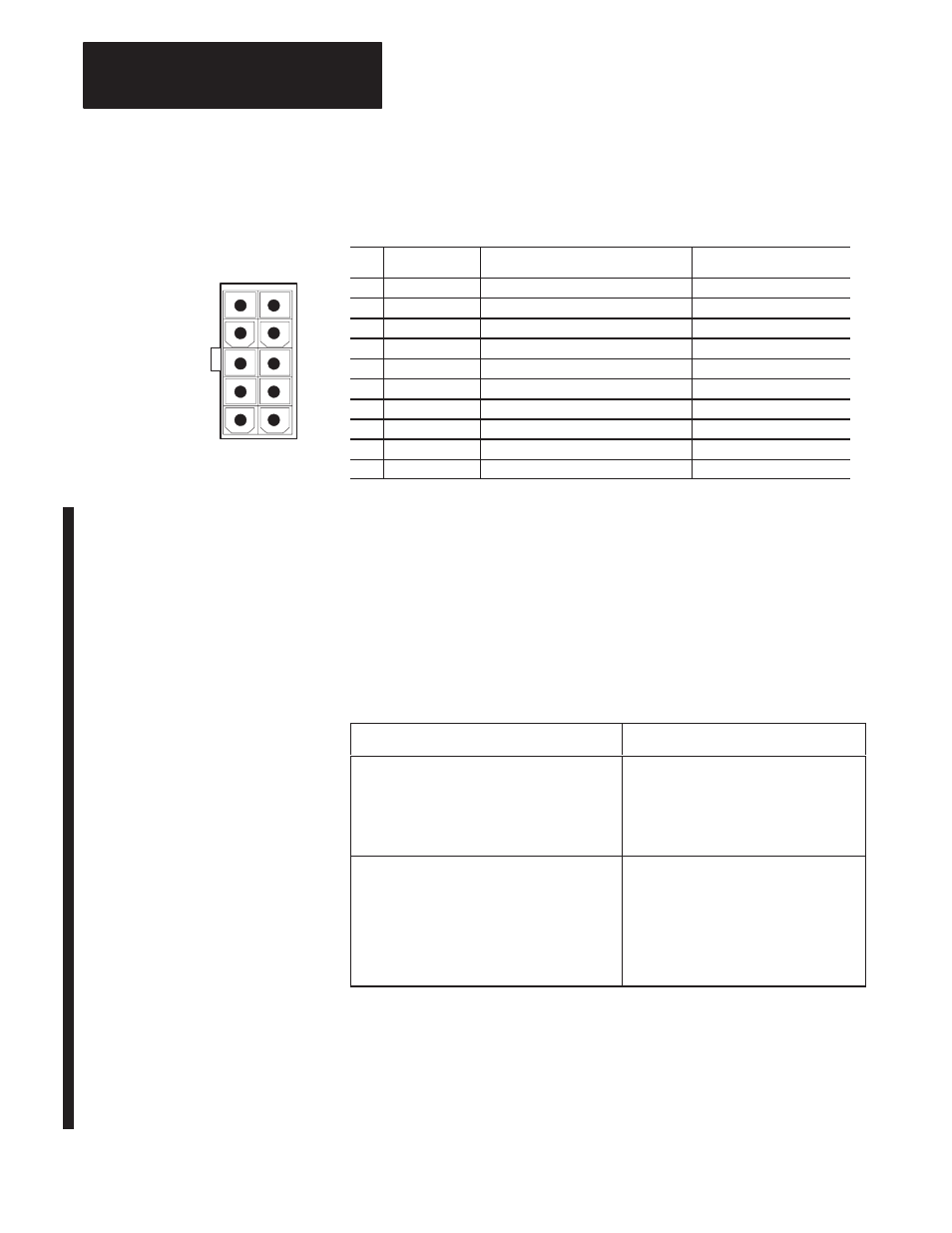

Figure 5A.10

Pin Configuration for the Resolver Connectors on the 9/440 Resolver–based

CNC/Drive

Pin

Signal

Description

Signal Destination

1

R1

Resolver Excitation +

Resolver

2

Shield

Shield Excitation (R1/R2)

3

S1

Feedback Sin +

Feedback Board

4

S2

Feedback Cos +

Feedback Board

5

Shield

Shield Cos. (C1/C2)

6

R2

Resolver Excitation –

Resolver

7

Shield

Shield Sin (S1/S2)

8

C1

Feedback Sin –

Feedback Board

9

C2

Feedback Cos –

Feedback Board

10

Shield

Overall Shield

Wiring Motor Power, Thermals, and Brakes

The procedures in this section assume that your system and axis modules

are already mounted. We recommend that you start at either the first or

last axis module, wire it completely, and then wire the module next to it

completely, and so on until they are all wired.

To wire your 1394 axis:

1.

If you have this type of system module:

then:

Series A or B

1. Bond one end of the axis module ground

wire to the subpanel.

2. Connect the other end of the ground wire

to terminal block PE1.

3. Go to main step 7.

Series C

1. Connect one end of the axis module

ground wire to the system module ground

bar.

2. Connect the other end of the ground wire

to terminal block PE1.

3. Go to main step 2. Refer to Figure 5A.11

for main steps 2 – 6.

Important: For more information about bonding, refer to your 1394

documentation.

Important: To improve the bond between the motor cable shield and the

axis module PE ground, a cable shield clamp is included with the Series C

axis modules.