Using a plc-2 with a sub i/o scanner, Block transfer example – Rockwell Automation 2705 RediPanel Push Button Module User Manual

Page 50

Chapter 4

Programming the RediPANEL Modules

4–11

When using a PLC-2 processor with RediPANEL module, the system must

contain a 1771-SN Sub I/O Scanner. Mini PLC-2 processors communicate

with remote I/O using this Sub I/O Scanner. The Sub I/O Scanner is located

in the same chassis as the mini PLC-2 and communicates with the PLC using

block transfers. The 1771-SN Sub I/O Scanner looks like an intelligent I/O

module to the PLC. You can also use Sub I/O Scanner in any chassis of a

PLC-2/20 or 2/30 system.

The 1771-SN requires one PLC scan to receive the output data from the

output image table and another PLC scan to send discrete input data to the

input image table. Anything connected to the Sub I/O Scanner is scanned

asynchronous to the PLC scan. The PLC then scans the Sub I/O Scanner

during the I/O portion of the PLC scan. See the section on Operating Cycles.

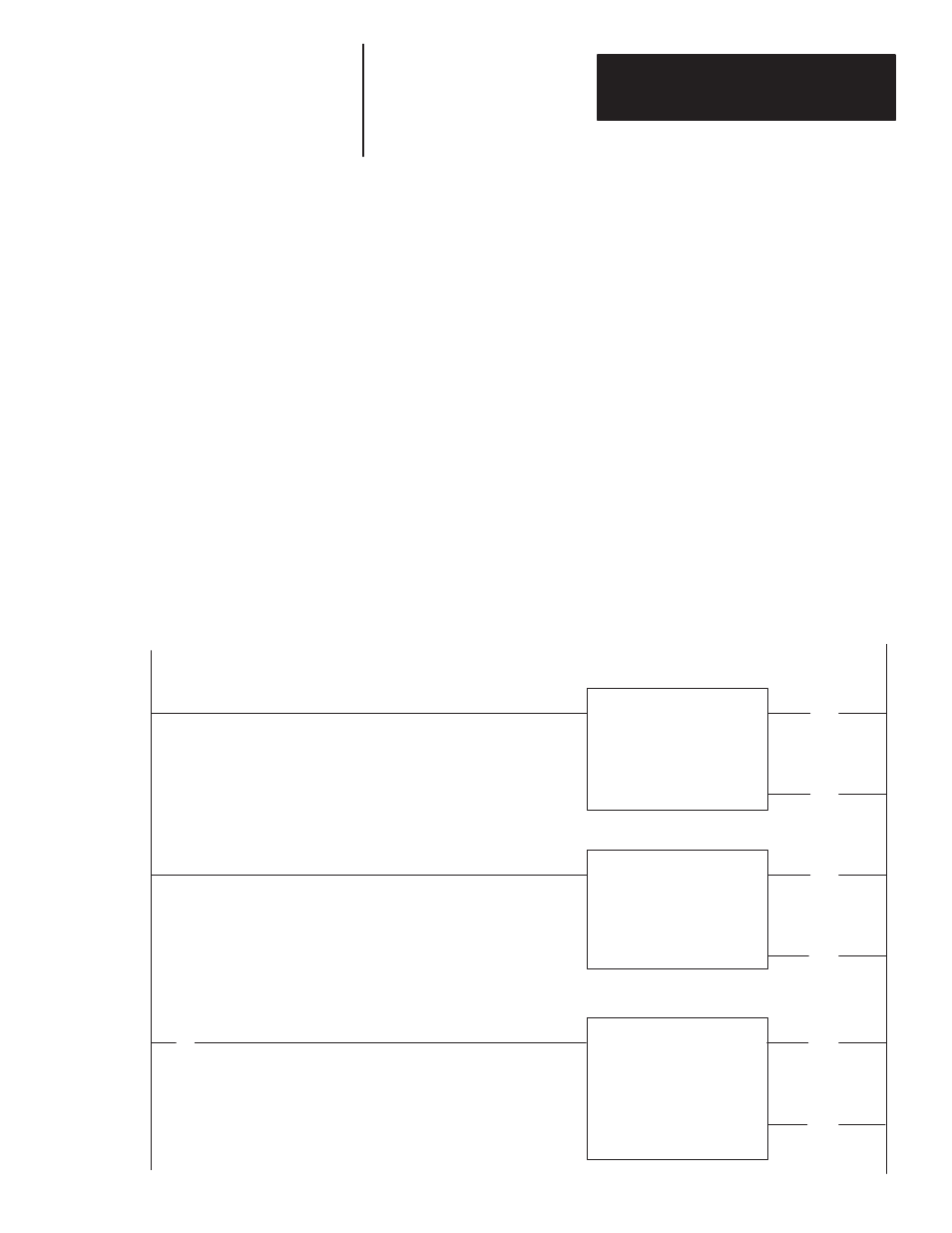

Block Transfer Example

Figure 4.2 shows an example of a block transfer between a Sub I/O Scanner

module and a PLC.

Figure 4.2

Block Transfer between Sub I/O Scanner and PLC–2

010

( EN )

17

Write information to the sub-scanner from PLC.

Read information from the sub-scanner into the PLC.

110

( DN )

17

BLOCK X-FER READ

DATA ADDR:

0030

MODULE ADDR:

101

BLOCK LENGTH:

014

FILE:

0200-0215

110

( DN )

16

010

( EN )

16

BLOCK X-FER WRITE

DATA ADDR:

0031

MODULE ADDR:

101

BLOCK LENGTH:

014

FILE:

0300-0315

Buffer the read information from the sub-scanner.

110

( DN )

16

010

( EN )

16

110

] [

17

FILE TO FILE MOVE

DATA ADDR:

0033

POSITION:

001

FILE LENGTH:

014

FILE A:

0200-0215

FILE R:

0400-0415

RAT PER SCAN:

014

1

2

3

Using a PLC-2

with a Sub I/O Scanner