Rockwell Automation 1794 FLEX I/O System with ControlLogix for SIL2 User Manual

Page 36

Publication 1794-RM001G-EN-P - December 2011

3-14 FLEX I/O Modules

•

Wire Output Back to Input and Examination of Output Data

Feedback signal: Users must wire an analog output to an actuator and

then back to an analog input to monitor the output’s performance. (The

use of feedback transmitters to verify an output’s performance is

acceptable.) The application logic must examine the Data Feedback

value associated with each output point to make sure that the requested

output command from the controller was received by the module. The

value must be compared to the analog input that is monitoring the

output to make sure the value is in an acceptable range for the

application.

In the ladder diagram in Figure 3.12, a user-defined percentage of

acceptable deviation (that is, tolerance) is applied to the configured

range of the analog input and output (that is, range) and the result is

stored (that is, delta). This delta value is then added to and subtracted

from the monitoring analog input channel; the results define an

acceptable High and Low limit of deviation. The analog Output

Feedback is then compared to these limits to determine if the output are

working properly.

The output’s OK bit preconditions a Timer run that is preset to

accommodate an acceptable fault response time and any communication

filtering, or output, lags in the system. If the monitoring input value and

the Output Feedback miscompare for longer than the preset value, a

fault is registered with a corresponding alarm.

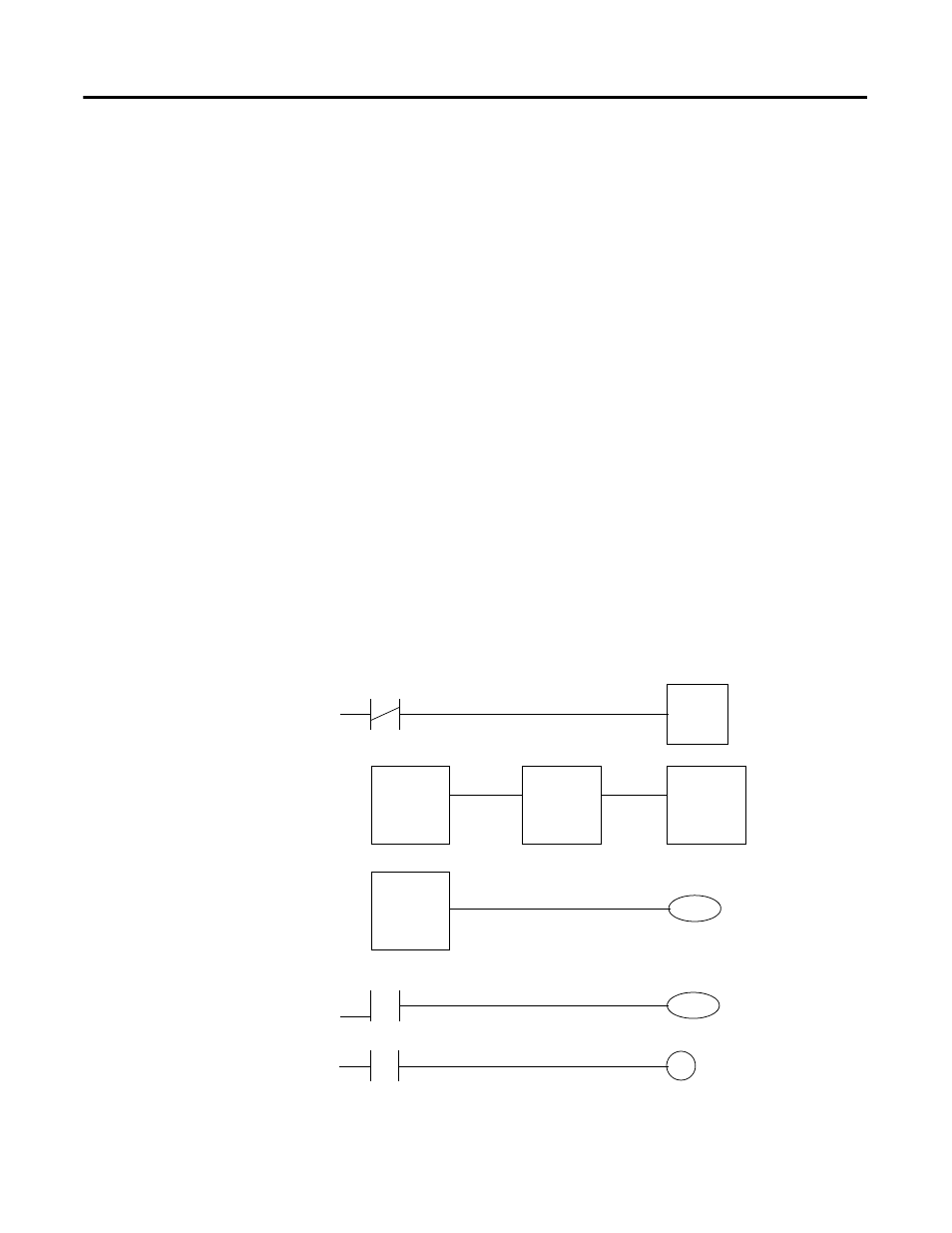

Figure 3.12 Monitoring an Analog Output with an Analog Input

The control, diagnostics and alarming functions must be performed in

sequence.

Timer done

Timer

Outputs Faulted

Alarm to Operator

Outputs OK

ADD

Delta

Monitoring input

High Limit

MULT

Range

Tolerance %

Delta

Outputs Faulted

LIM

Low Limit

Output Echo

High Limit

Outputs OK

SUB

Delta

Monitoring input

Low Limit