Wiring flex i/o digital input modules, Figure 3.2, Figure 3.3 – Rockwell Automation 1794 FLEX I/O System with ControlLogix for SIL2 User Manual

Page 25

Publication 1794-RM001G-EN-P - December 2011

FLEX I/O Modules 3-3

Wiring FLEX I/O Digital

Input Modules

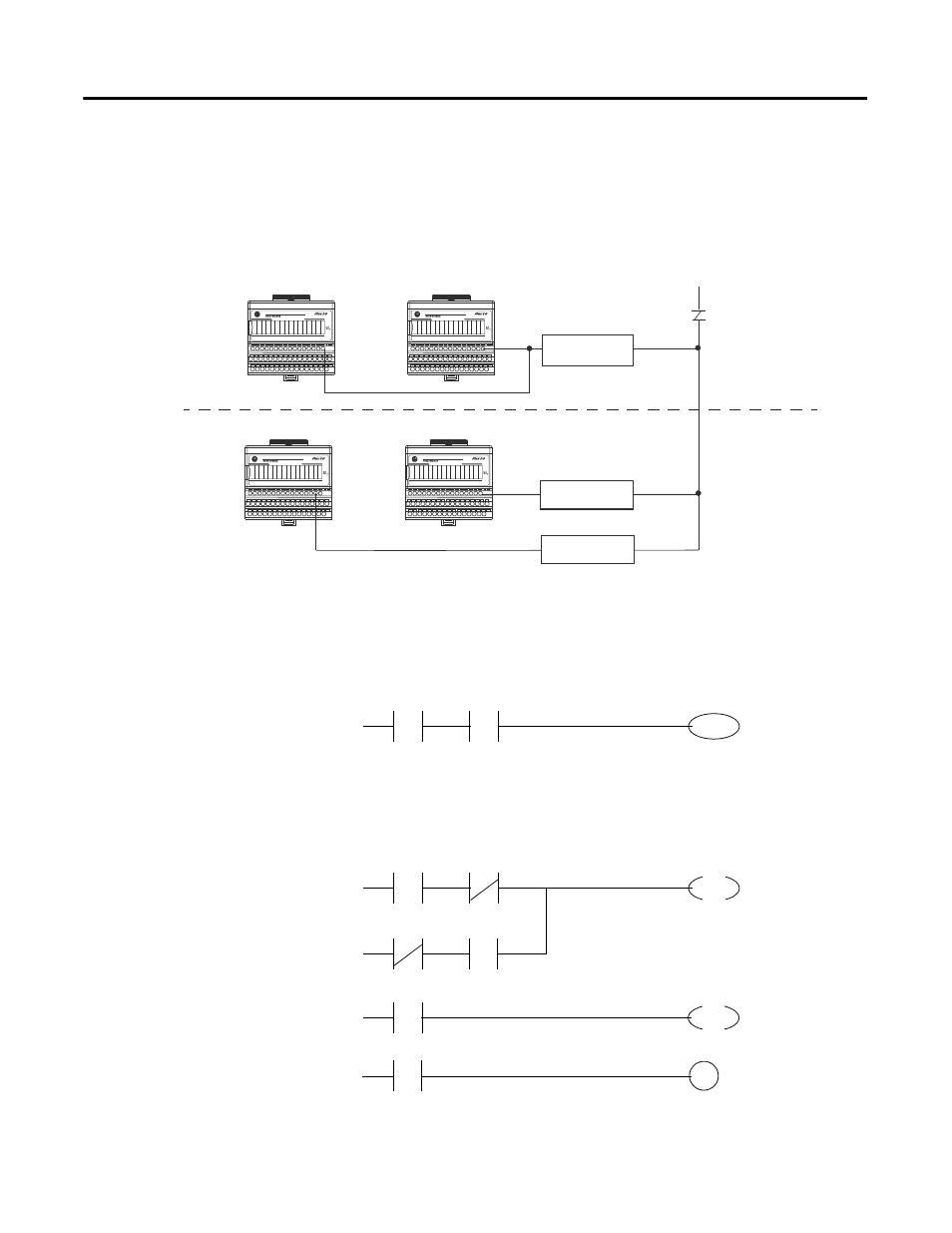

The wiring diagrams in Figure 3.1 show two methods of wiring the digital

input Module. In either case, users must determine whether the use of 1 or 2

sensors is appropriate to fulfill SIL2 requirements.

Figure 3.1 ControlLogix Digital Input Module Wiring

Application logic can compare input values or states for concurrence.

Figure 3.2

The user program must also contain rungs to annunciate a fault in the event of

a sustained miscompare between two points.

Figure 3.3

Input 1

Input 2

Input

COM

+24V

1 2

3 4 5

6 7

8 9 10 11 12 13 14 15

0

24VDC SINK INPUT

1794-IB16

1 2

3 4 5

6 7

8 9 10 11 12 13 14 15

0

24VDC SINK INPUT

1794-IB16

1 2

3 4 5

6 7

8 9 10 11 12 13 14 15

0

24VDC SINK INPUT

1794-IB16

1 2

3 4 5

6 7

8 9 10 11 12 13 14 15

0

24VDC SINK INPUT

1794-IB16

Input

COM

+24V

Input 1

Input 2

SIL2 SENSOR

SENSOR

SENSOR

+24V dc

Optional relay contact

to switch line voltage

for periodic automated

testing

43366

One-Sensor Wiring Example

Two-Sensor Wiring Example

43366

Note 1: Both sensors are monitoring the same safety application.

1

1

Input B

Input A

Actuator

Input B

Input A

Input B

Input A

Timer

Timer preset in milliseconds to

compensate for filter time and

hardware delay differences.

Fault

Timer Done

Alarm to Operator

Fault