What are typical applications, System requirements, What are typical applications? system requirements – Rockwell Automation 1746-QS,D17466.19 SYNCHRONIZED AXES MODULE User Manual

Page 8

1–4

Publication 1746-6.19 March 1998

Ladder logic transfers motion commands to the module and axis

status from the module thru the I/O image table. Ladder logic also

copies configuration parameters to the module’s M0 file at power up.

It also copies configuration parameters (that you enter/change with

the Hydraulic Configurator) from the module’s M1 file to processor

files. Thus, you can establish a library of configurations (recipes) in

processor files that you can select and download to the module at

power up or each time you want to change the setup of your axes.

We explain the functions of the ladder logic later in this manual.

Use the module in an SLC-based system for control of hydraulic

applications where two or more axes must reach their final position

at the same time, such as:

•

plywood presses

•

roll positioning

•

palletizers and stackers

•

forging machines

•

hydraulic tailgate loaders

In addition, the module is designed to support independent axes using

either servo or proportional amplifiers, and retrofit into existing

hydraulic systems requiring a positive voltage irrespective of direction.

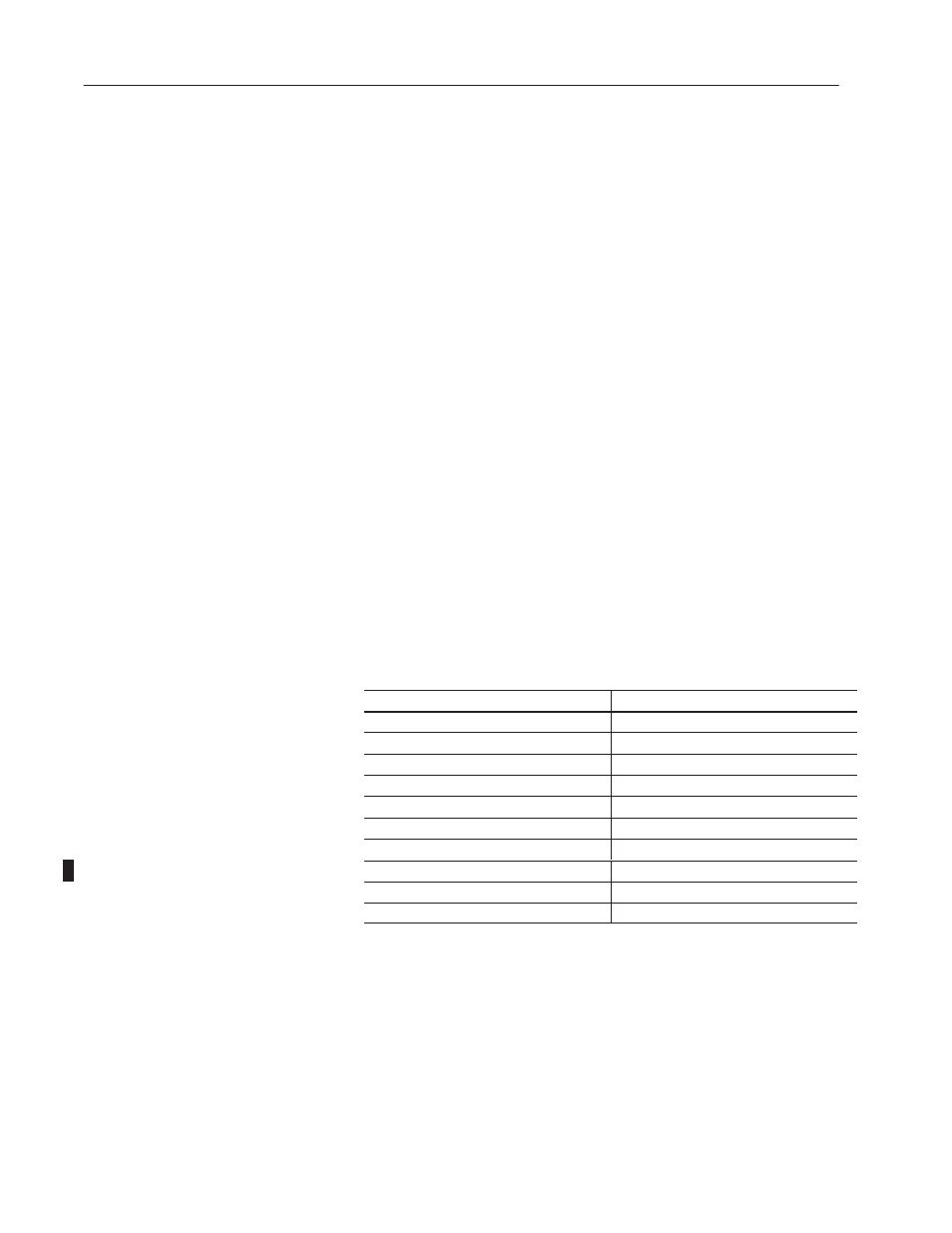

Hardware/software requirements of this SLC processor system include:

Component:

Requirement:

SLC Processor

SLC 5/03 or later

Comm. Interface Card (alternate COM port)

1784-KTx

Personal Computer

3.9 MByte of disk space

PC Operating System

Windows 95

PC/QS Interface Cable

1747-CP3

Synchronized Axes Module

1746-QS

Interface Module (terminal block)

1492-AIFMQS

Interface Module Cable

1492-ACABLExxxQ

Programming Software

RSLogix500

LDT (RPM or DPM)

Temposonics, Baluff, Santest, Gemco, etc

What Are Typical

Applications?

System Requirements