Using i/o image tables for commands and status – Rockwell Automation 1746-QS,D17466.19 SYNCHRONIZED AXES MODULE User Manual

Page 47

Using Processor Files

C–5

Publication 1746-6.19 March 1998

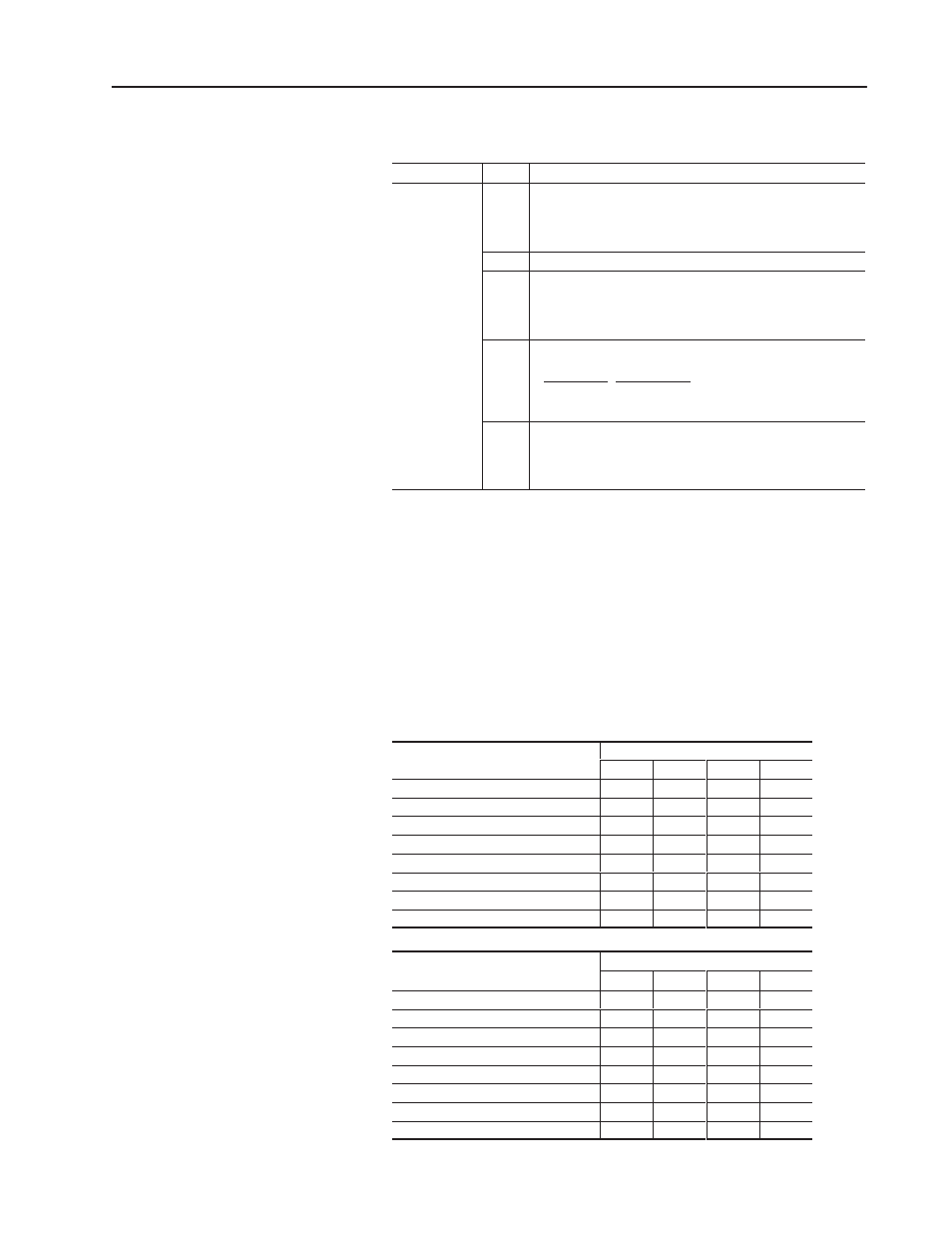

Bit Map of Configuration Word (e:0, e:16, e:32. e:48)

Word

Bit

Description

Configuration

(bit ap)

15-12

Number of LDT recirculations = bit combination.

bit 15 = 8 recirculations

bit 14 = 4 recirculations

bit 13 = 2 recirculations

bit 13 = 1 recirculation

(bit map)

11-04

Reserved

03

Simulate mode, used for debugging.

= 1 Drive output is set to null, LDT inputs are ignored.

Internally, the target position is used as the actual position.

(LDT error bits and LEDs are cleared.)

= 0 Simulate mode ignored.

02-01

Divide LDT counts = bit combination; used to reduce LDT count

resolution for long strokes or high speeds

Bit 02 Bit 01 Divide counts by

0

1

2

1

0

4

1

1

8

0

Integrator limit, to help prevent drive output saturation.

If integrator = limit, integrator windup bit in status word is set, and

integrator value is held to the limit.

=1 limit is 80% of full drive

=0 limit is 20% of full drive

Motion-control command words for all four axes are sent to the

module through the output image table, and axis status words of all

four axes are returned from the module through the input image table.

The ladder program may write 32 command words (for all four axes)

from an integer file to the output image table (by a COPY instruction),

and may read 32 status words (for all four axes) from the input image

table (by a COPY instruction) into another integer file.

Eight output image words per axis (for commands) and eight input

words per axis (for status) are addressed as follows:

Your Ladder Logic Must

To These Output Image Addresses:

Your Ladder Logic Must

Write These Parameters

Axis 1

Axis 2

Axis 3

Axis 4

Mode

O:e.0

O:e.8

O:e.16

O:e.24

Acceleration

O:e.1

O:e.9

O:e.17

O:e.25

Deceleration

O:e.2

O:e.10

O:e.18

O:e.26

Speed

O:e.3

O:e.11

O:e.19

O:e.27

Position/Command Value

O:e.4

O:e.12

O:e.20

O:e.28

Command

O:e.5

O:e.13

O:e.21

O:e.29

Reserved

O:e.6

O:e.14

O:e.22

O:e.30

Reserved

O:e.7

O:e.15

O:e.23

O:e.31

Your Ladder Logic Must

Rea These arameters

At These Input Image Addresses:

Your Ladder Logic Must

Read These Parameters

Axis 1

Axis 2

Axis 3

Axis 4

Commanded Position

I:e.0

I:e.8

I:e.16

I:e.24

Target Position

I:e.1

I:e.9

I:e.17

I:e.25

Actual Position

I:e.2

I:e.10

I:e.18

I:e.26

LDT Counts

I:e.3

I:e.11

I:e.19

I:e.27

Status Bits

I:e.4

I:e.12

I:e.20

I:e.28

Drive Output

I:e.5

I:e.13

I:e.21

I:e.29

Actual Speed

I:e.6

I:e.14

I:e.22

I:e.30

Drive Null

I:e.7

I:e.15

I:e.23

I:e.31

Using I/O Image Tables

for Commands and Status