Why use this system, How does it work, Why use this system? how does it work – Rockwell Automation 1746-QS,D17466.19 SYNCHRONIZED AXES MODULE User Manual

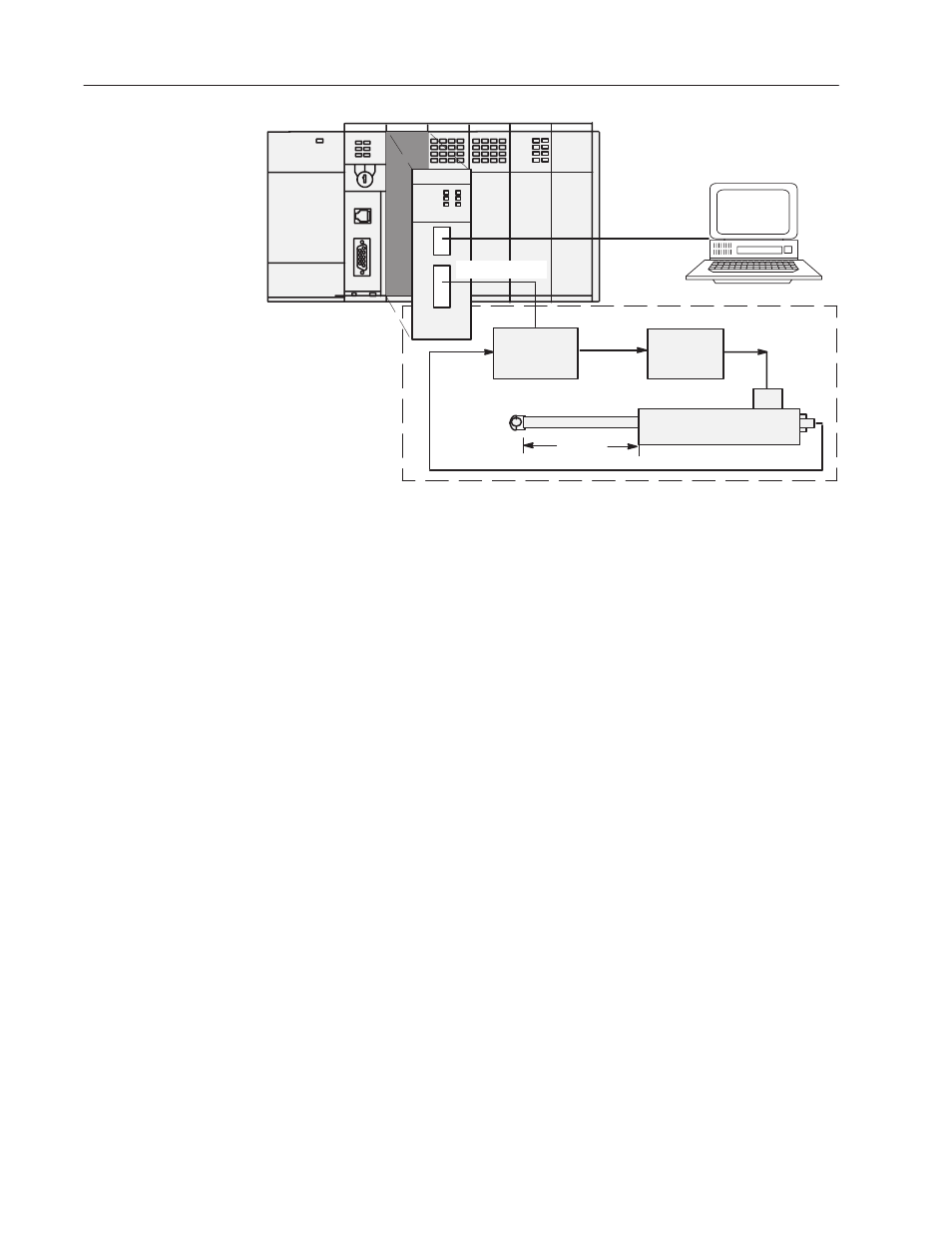

Page 6: Monitoring axis position, Controlling axis output

1–2

Publication 1746-6.19 March 1998

Power

Supply

SLC-500

Processor

Analog

Output

"10V dc

Servo-quality

Proportional

Valve

Proportional

Amplifier

Axis

Motion

Position

Input

Piston-type Hydraulic Cylinder

and Position-monitoring Device

One of Four Identical Motion-control Loops

Interface Module

(terminal block)

1492-AIFMQS

HYDRAULIC

SYNCHR AXES

1746-QS

module

1747-CP3

Cable

1492-ACABLE015Q

Hydraulic Configurator

Software on PC

For Setup and

Troubleshooting

Because you can interact quickly and easily with the module’s control of

axis motion via the Hydraulic Configurator, this control system has

these benefits:

•

faster setup and tuning of axes – the Hydraulic Configurator lets you

quickly set up and tune each axis independent of your ladder program.

•

reduced cycle time – you can increase axis speed for faster operation

•

smoother operation for longer machine life – you can profile acceler-

ations and decelerations of the hydraulic actuator to limit pressure spikes

•

faster change-over to new parts – you can store setups (configuration

parameters) for quick an accurate change-over between parts

Monitoring Axis Position

The module has four LDT inputs. You configure each axis for an LDT

with a Pulse Width Modulated output (DPM) or a Start/Stop output

(RPM) by changing axis configuration parameters.

Controlling Axis Output

The module is a targeting controller: every two milliseconds its micro-

processor updates

TARGET POSITION

and target SPEED values. For

point-to-point moves,

TARGET POSITIONS

are generated so that

resulting speed, accelerations, and decelerations follow either a

trapezoidal or s-curve profile.

Why Use This System?

How Does It Work?