Bit map of command mode word, Bit map of axis status word – Rockwell Automation 1746-QS,D17466.19 SYNCHRONIZED AXES MODULE User Manual

Page 48

Using Processor Files

C–6

Publication 1746-6.19 March 1998

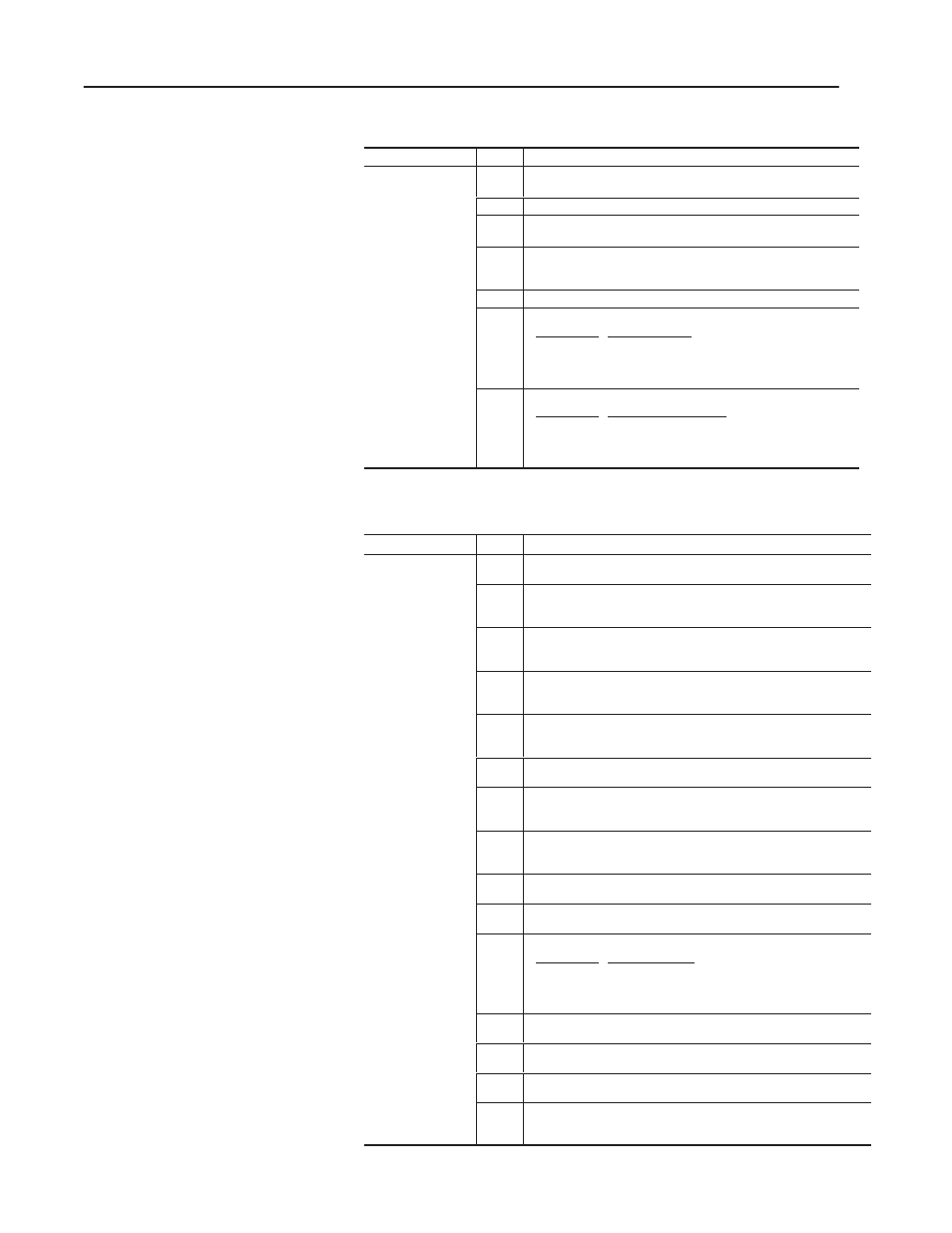

Bit Map of Command Mode Word

Word

Bit

Description

15

0 =

plots each move of the axis, overwwriting previous plot

1 =

disables axis plot to preserve the last plot

Command Mode

(Co

and word )

14-08

reserved

Co

and Mode

(Command word 0)

07

0 = disables S Curve

1 = module computes an S-curve target for smoother motion

06

0 = disables Quick Mode

1 = module ramps up to (max) drive output in open loop,

maintains it, then ramps down in closed loop axis limit

05-04

Synch A/B: Axes with same bit set are synchronized

03-02

Integrator Mode = bit combination

Bit 03 Bit 02 Integrator is Active

0

0

always

0

1

during DECEL and IN POSITION

1

0

during IN POSITION

1

1

never

01-00

Accel/Decel Mode = bit combination

Bit 01 Bit 00 Accel/Decel values define:

0

0

ramp rate in position units/sec/sec

0

1

ramp rate in 1000 position units/sec/sec

1

0

distance to SPEED

1

1

time to SPEED

Bit Map of Axis Status Word

Word

Bit

Description

15

0 =

LDT input OK

1 =

LDT input lost

14

0 =

LDT input OK

1 =

LDT input noisy

For hard/soft stop, see config auto-stop, bit 06

Axis Status

(Statu word 4)

13

0 =

LDT input OK

1 =

LDT input overflow

For hard/soft stop, see config auto-stop, bit 05

Axis Status

(Status word 4)

12

0 =

output drive power OK

1 =

output drive exceeds D/A range (insufficient drive power)

For hard/soft stop, see config auto-stop, bits 12 and 04

11

0 =

no parameter error detected

1 =

initialization or control parameter is out of bounds

For hard/soft stop, see config auto-stop, bits 11 and 03

10

0 =

no position overflow detected

1 =

actual position exceeded range of 16-bit number display

09

0 =

integrator windup OK

1 =

integrator value exceeded 20% or 80% (see config bit 00)

For hard/soft stop, see config auto-stop, bits 09 and 01

08

0 =

following error OK

1 =

difference between target and actual positions > max error

For hard/soft stop, see config auto-stop, bits 08 and 00

07

0/1 = toggles to acknowledge valid command or status request

received by the module

06

0 =

module not initialized (module is reset)

1 =

initialized with P command (axis ready for Go command)

05-04

State of target generator = bit combination

Bit 05 Bit 04 Target Generator is

0

0

stopped

0

1

accelerating

1

0

at constant speed

1

1

decelerating

03

0 =

axis in closed loop

1 =

axis in open loop, caused by O command or hard stop

02

0 =

axis movement

1 =

axis is halted, caused by H command, hard or soft stop

01

0 =

axis movement

1 =

axis speed < 500 transducer counts (cleared @ 1000 cts)

00

0 =

axis outside in-position window

1 =

difference between actual and command positions is less

then the in-position value