Rockwell Automation 1746-QS,D17466.19 SYNCHRONIZED AXES MODULE User Manual

Page 22

4–6

Publication 1746-6.19 March 1998

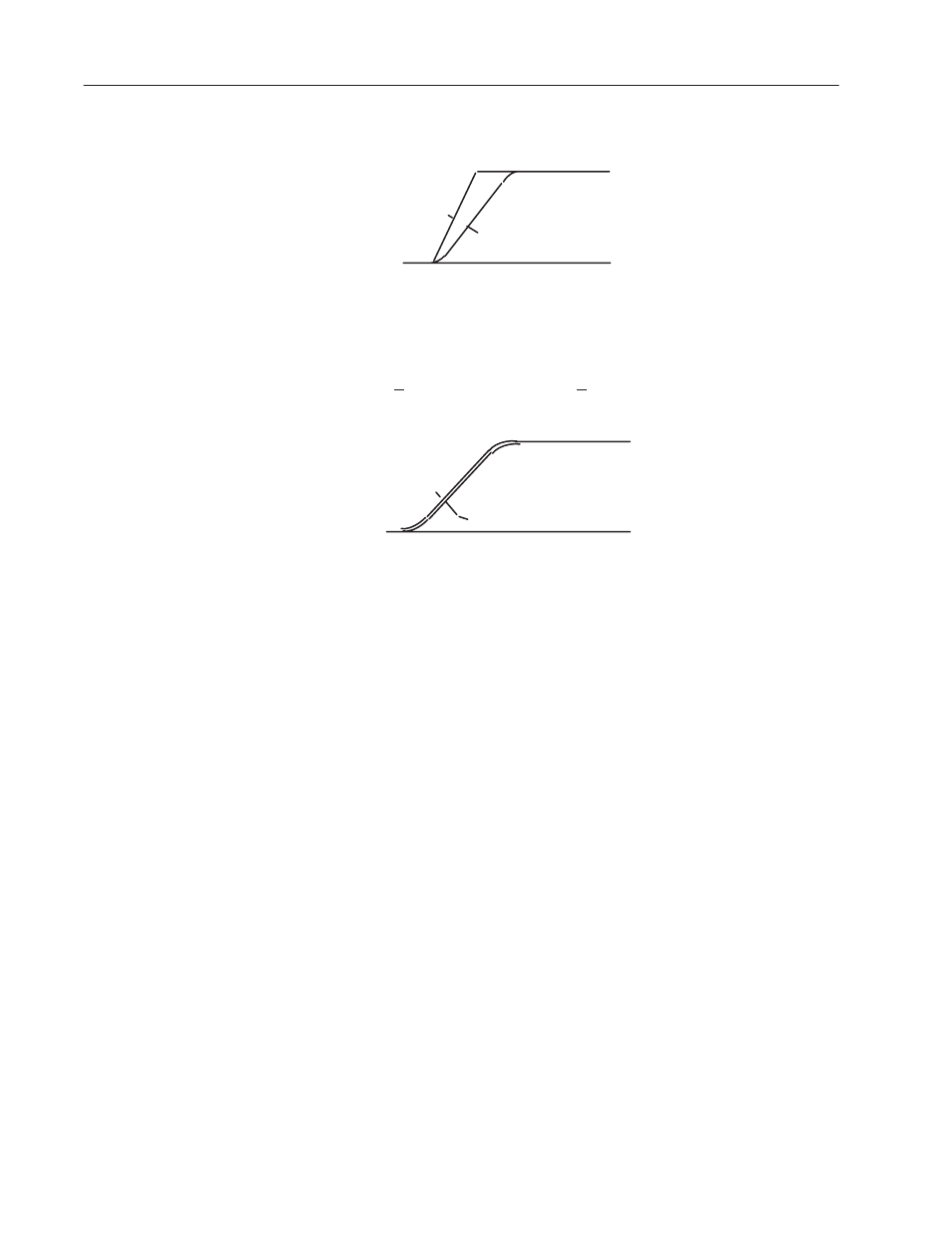

2. The Following Error will probably vary as indicated by diverging plots

of target and actual speeds during acceleration or deceleration.

Target Speed

(pink)

Actual Speed

(dark blue)

Following Error

3. To achieve a nearly constant steady-state Following Error, increase

the

PROPORTIONAL GAIN

until the plots of target and actual speeds

become parallel during acceleration or deceleration.

4. To minimize the Following Error, use the auto Adjust Feedforward

“F” command. With each “F” command, the module boosts

(prescales) the drive output by increasing the

FEEDFORWARD

term.

This brings the plots of target and actual positions to coincide.

Target Position

(powder blue)

Following Error

Actual Position

(red)

For additional information, refer to Feedforward Parameters, below.

5. For critical tuning, adjust the

ACCELERATION FEEDFORWARD

term.

To do this, observe the Sum-Error

2

value found in the window on the

plot screen. Repeat axis moves with adjustments until Sum-Error

2

value reaches a minimum. Too much

ACCELERATION

FEEDFORWARD

will increase the Sum-Error

2

value.

Important: Critical tuning may increase pressure spikes. If the

axis load is too large, consider lowering your expectations of

machine performance and use smaller accel/decel values in the

motion command. Using the S-curve feature (Command Mode)

is another alternative.

For additional information on Acceleration Feedforward, refer to

Using Acceleration Feedforward, below.

6. For end-point stability, adjust the

PROPORTIONAL GAIN

(and

INTEGRAL GAIN)

to minimize the end-point position error by either

of two ways. Adjust P and/or I until the:

– end position oscillates. Then back down to 75% of P.

– Sum-Error

2

value no longer decreases with each adjustment.

Remember to enter an

IN POSITION

value in the Config word to

monitor end-position stability.