Programming – Rockwell Automation 1746-QS,D17466.19 SYNCHRONIZED AXES MODULE User Manual

Page 7

1–3

Publication 1746-6.19 March 1998

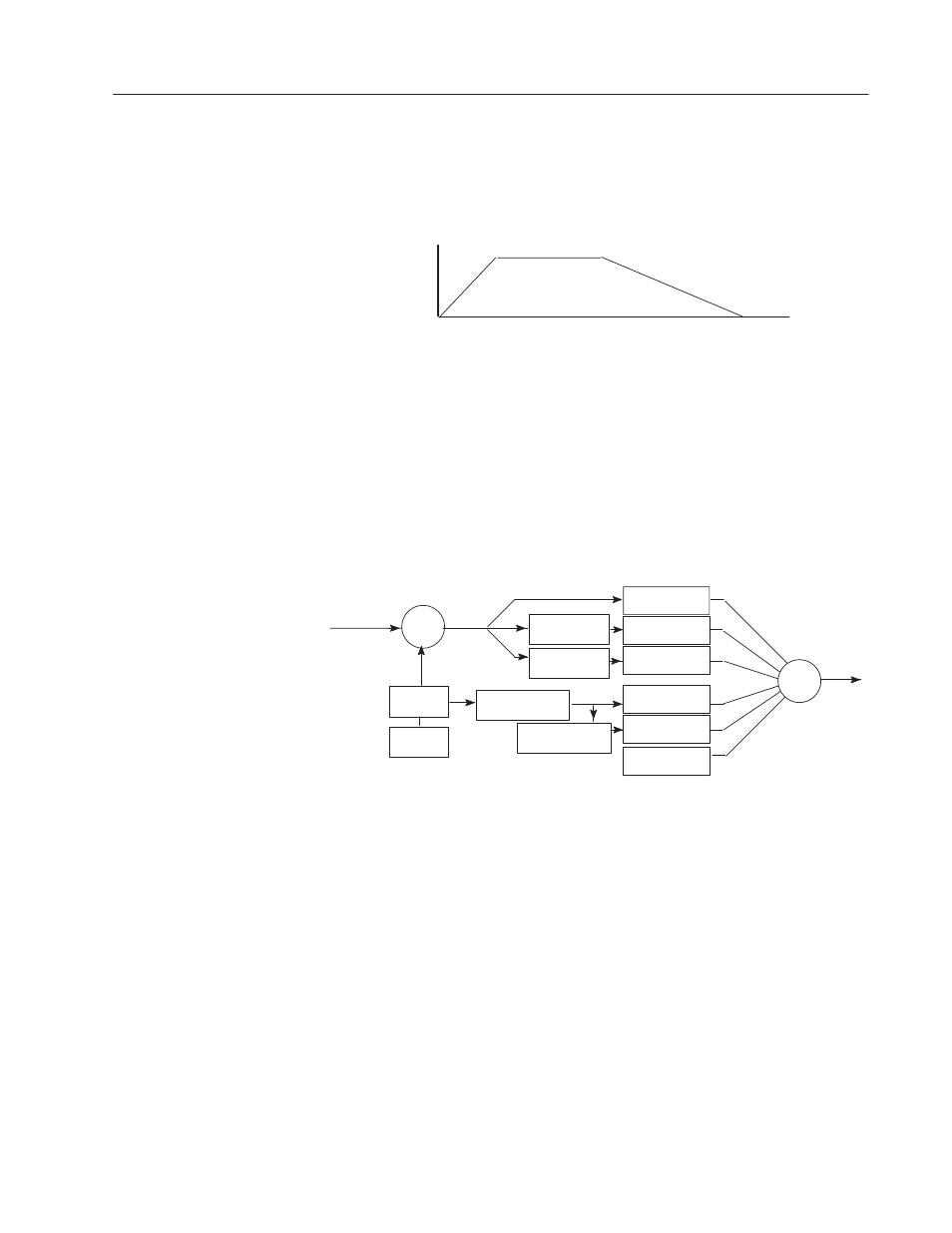

The

MODE, ACCELERATION, DECELERATION, SPEED,

and

COMMAND VALUE

(requested position) are used to generate the

profile. You send these command words to the module through the

processor’s output image table. You may change them “on-the-fly“

while the axis is moving.

Motion Profile

Speed

Time

Accel

Ramp

Decel

Ramp

Max Speed

Command Value

(Final Position)

The module compares

ACTUAL POSITION

with

TARGET POSITION

to

determine position error. Every update, it uses the position error to adjust

drive output. PID gains are adjustable and can be applied selectively.

The module also provides two different feedforward algorithms;

EXTEND

/

RETRACT FEEDFORWARD

, and

EXTEND

/

RETRACT

ACCELERATION FEEDFORWARD

. These feedforward terms provide

additional drive output to help the axis follow the target, freeing the

PID loop to correct for system nonlinearity and changes in load.

Diagram of the Control Loop

Proportional Gain

Integral Gain

Differential Gain

Feedforward

Accel

Feedforward

Deadband

Eliminator

Accumulator

(Integrator)

Change in Error

(Differentiator)

Change in Position

(Velocity)

Change in Velocity

(Acceleration)

Target

Generator

SLC

Processor

Position

Error

Actual

Position

Target

Position

Drive

Output

+

–

ȍ

ȍ

Programming

A sample ladder program for the module is available from

Allen-Bradley’s website on the Internet. You can download it as an

executable file to your PC’s disk drive and transfer it to your SLC

processor. But, you must modify it for your application.