Ladder file 2 -19, Ladder file 2 – Rockwell Automation 1746-NI16V SLC 500 Analog Input Modules User Manual User Manual

Page 97

Publication 1746-UM001A-US-P

Application Examples 7-19

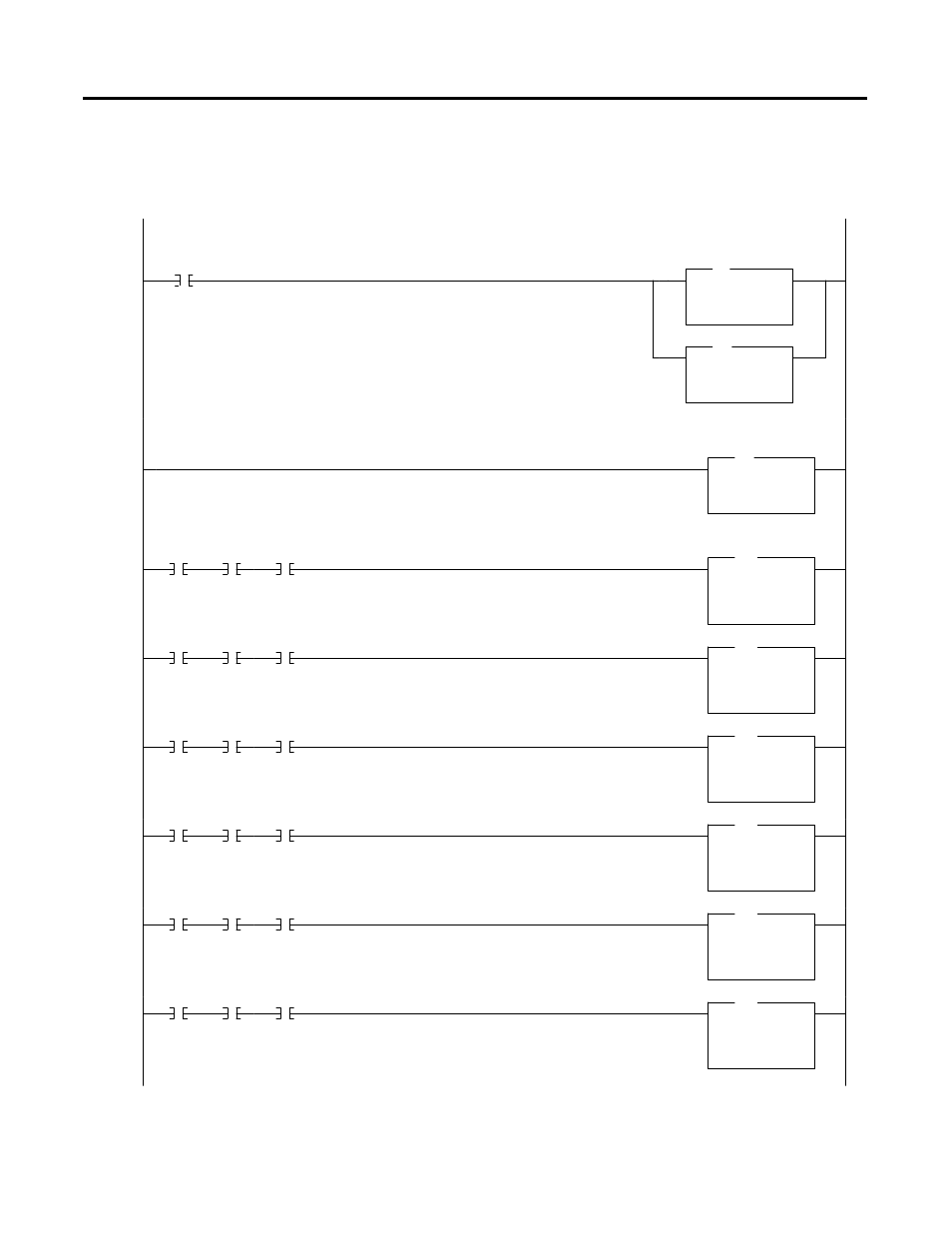

Ladder File 2

0000

S:1

15

First Pass

FLL

Fill File

Source

0

Dest

#I:6.0

Length

32

FLL

COP

Copy File

Source

#N7:0

Dest

#O:6.0

Length

16

COP

0001

COP

Copy File

Source

#I:6.16

Dest

#N7:46

Length

16

COP

0002

N7:46

13

N7:46

14

N7:46

15

MOV

Move

Source

I:6.0

0<

Dest

N7:30

0<

MOV

0003

N7:47

13

N7:47

14

N7:47

15

MOV

Move

Source

I:6.1

0<

Dest

N7:31

0<

MOV

0004

N7:48

13

N7:48

14

N7:48

15

MOV

Move

Source

I:6.2

0<

Dest

N7:32

0<

MOV

0005

N7:49

13

N7:49

14

N7:49

15

MOV

Move

Source

I:6.3

0<

Dest

N7:33

0<

MOV

0006

N7:50

13

N7:50

14

N7:50

15

MOV

Move

Source

I:6.4

0<

Dest

N7:34

0<

MOV

0007

N7:51

13

N7:51

14

N7:51

15

MOV

Move

Source

I:6.5

0<

Dest

N7:35

0<

MOV

At power-up, clear the input image table for the NI16 to be sure old status and analog data is not used and then copy the configuration

words for each of the analog modules’16 channels. These configuration words are stored from N7:0 through N7:15.

Continually read the 16 status words for the 16 analog channels and store them in data table words N7:61. These words contain “Error

Conditions” for each channel, which are monitored in the following 16 rungs to determine if the data is valid before using it. These

“Error Condition” bits are 13, 14, and 15 of each channel status word, i.e. they must all be set to indicate “No Error” for each channel.

This rung and the following 15 rungs copy the analog data from the 1746-NI16 module’s 16 channels. The data is moved and is therefore

considered valid only when the channels associated status word “Error Condition” bits (13 to 15) are all set indicating “No Error”.