Rockwell Automation 1746-MPM INSTALL INSTRUC MOLD PRESSURE User Manual

Page 3

Mold Pressure Module

3

Publication 1746-5.13 July 1998

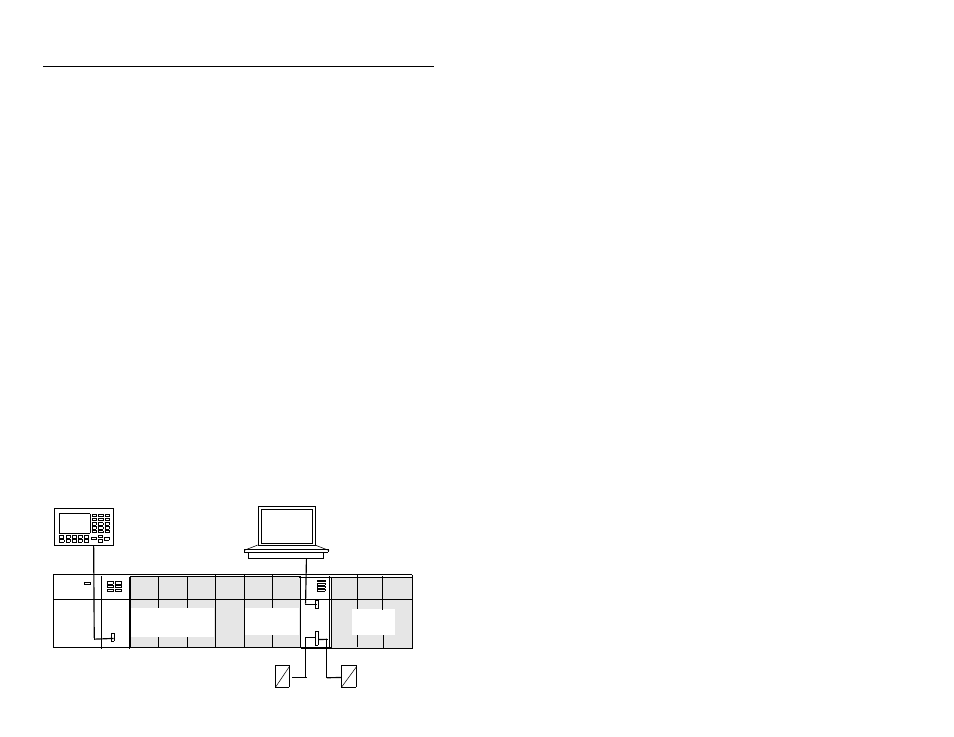

1. What the module does

The module processes and extracts cyclic injection molding data for

display on your PC, and responds to alarms that you set to monitor

critical molding parameters.

When used with the Pro-Set 200 Injection Molding Control System,

the module helps you:

•

achieve a quicker setup time to obtain optimum part quality

•

maintain that quality over the production run

The module and associated DARTWin software help you to set up the

injection molding machine for optimum performance. Then you set

alarm limits on critical parameters to detect deviations while making

parts. You can also set a critical mold pressure to transfer the injection

process each machine cycle.

The module is designed for use with the SLC 5/03 (or later) processor.

You program it to interface with the injection molding machine. The

module has two independent channels to accept analog pressure inputs

from sensors or from the SLC processor across the backplane. It

returns alarm signals and processed molding parameters to the SLC

processor for your application programming and to your PC for

graphic display. We show the module in a typical Pro-Set 200 system.

Power

Supply

SLC

5/04P

Empty

Slot

1746-

MPM

Fast Analog

I/O Modules

Barrel Temp

Modules

Digital I/O

Modules

4-wire sensor

(mold pressure)

2-wire sensor

(hydraulic pressure)

PanelView 550

Operator Interface

Personal Computer with

DARTWin Software

SLC 500 Processor System with

I/O and special-purpose modules

I/O for Injector,

Clamp, & Ejectors

P

T

P

T