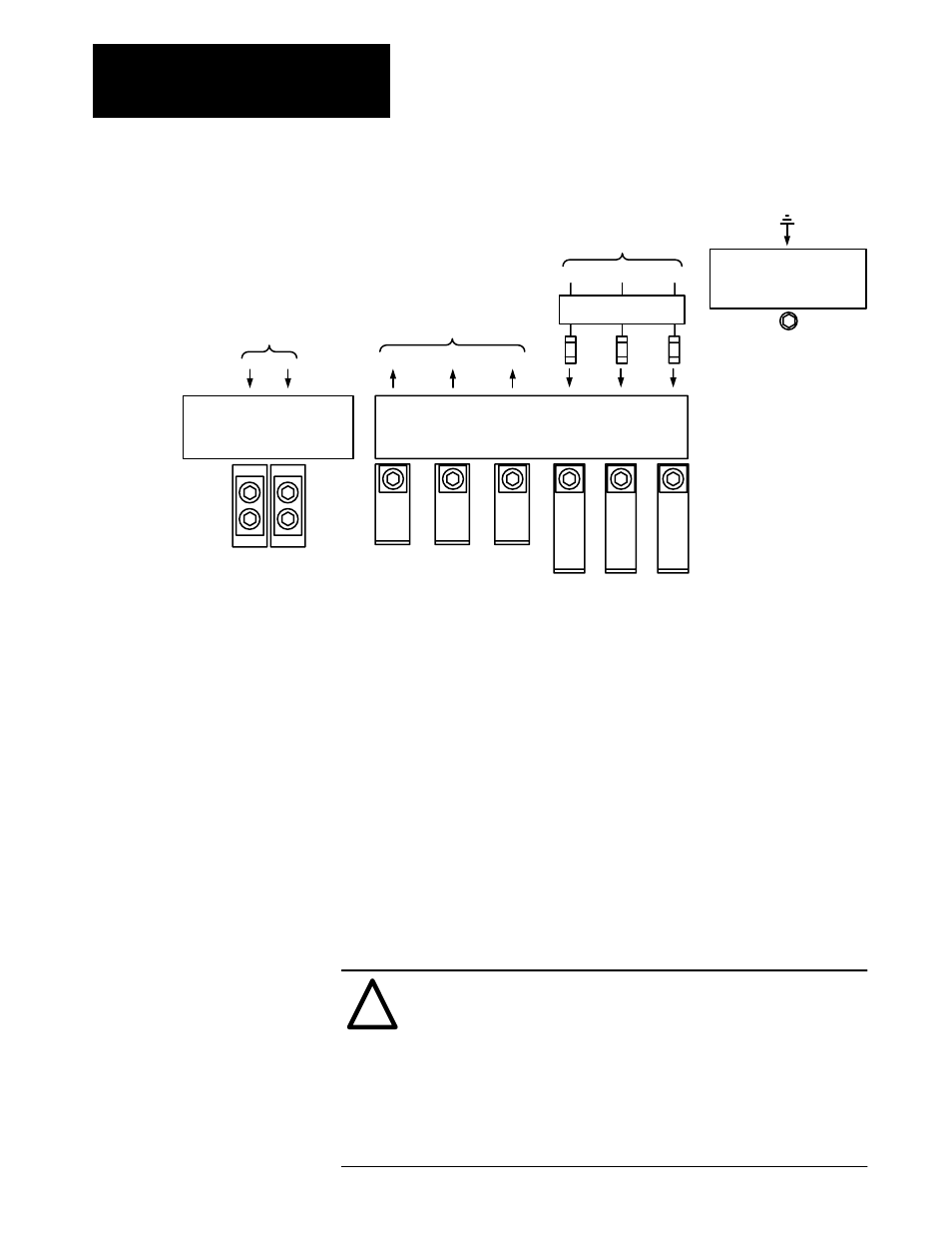

Dc, - dc, M1, m2, m3, Connect the motor leads to these terminals – Rockwell Automation 1336VT 5-300 AMP (2.2-160KW) User Manual

Page 58

Wiring

Chapter 6

6-14

+DC

-DC

M1

M2

M3

L1

L2

L3

USE 755C COPPER WIRE ONLY

WIRE RANGE 350 MCM - 6 AWG

TIGHTENING TORQUE 275 INCH

POUNDS

USE 755C COPPER WIRE ONLY.

WIRE RANGE 500 MCM - 0 AWG

TIGHTENING TORQUE 375 INCH

POUNDS

jA

jB

jC

jA

jB

jC

❶

❶

❶

Terminal Block TB1 -

240Ć300ĂAmp Power Wiring

Motor

AC Incoming Line

1336

Dynamic

Brake

Earth

Ground

USE 755C COPPER WIRE ONLY

WIRE SIZE 2 (3) AWG

TIGHTENING TORQUE 275 INCH POUNDS

GND

❷

❶

User supplied drive input fuses.

❷

Motor disconnecting means including branch circuit, short circuit, and ground fault protection.

GND

Chassis ground is used to connect the drive chassis to a common ground.

The motor frame must also be connected to the same common ground.

Either earth ground or the ground of the building system must be used.

Refer to the motor manufacturer’s guidelines for additional information.

+ DC, - DC

DC bus terminals are reserved for the 1336 dynamic brake option. Refer to

the 1336 dynamic brake option instructions for installation and connection

details.

M1, M2, M3

Connect the motor leads to these terminals.

!

ATTENTION: A hazard of potential damage to drive output

power components exists if there is insufficient load inductance to

permit the drive short circuit protection function to be effective.

Sufficient load inductance is provided by one of the following:

•

Option 1336-MOD-LR.

•

Load reactors of 10mH connected to each motor lead.

•

Motor leads with a minimum length of 40 feet (12.2 meters)

between the drive and the motor.