Wire group numbers, Wiring chapter 6 – Rockwell Automation 1336VT 5-300 AMP (2.2-160KW) User Manual

Page 47

Wiring

Chapter 6

6-3

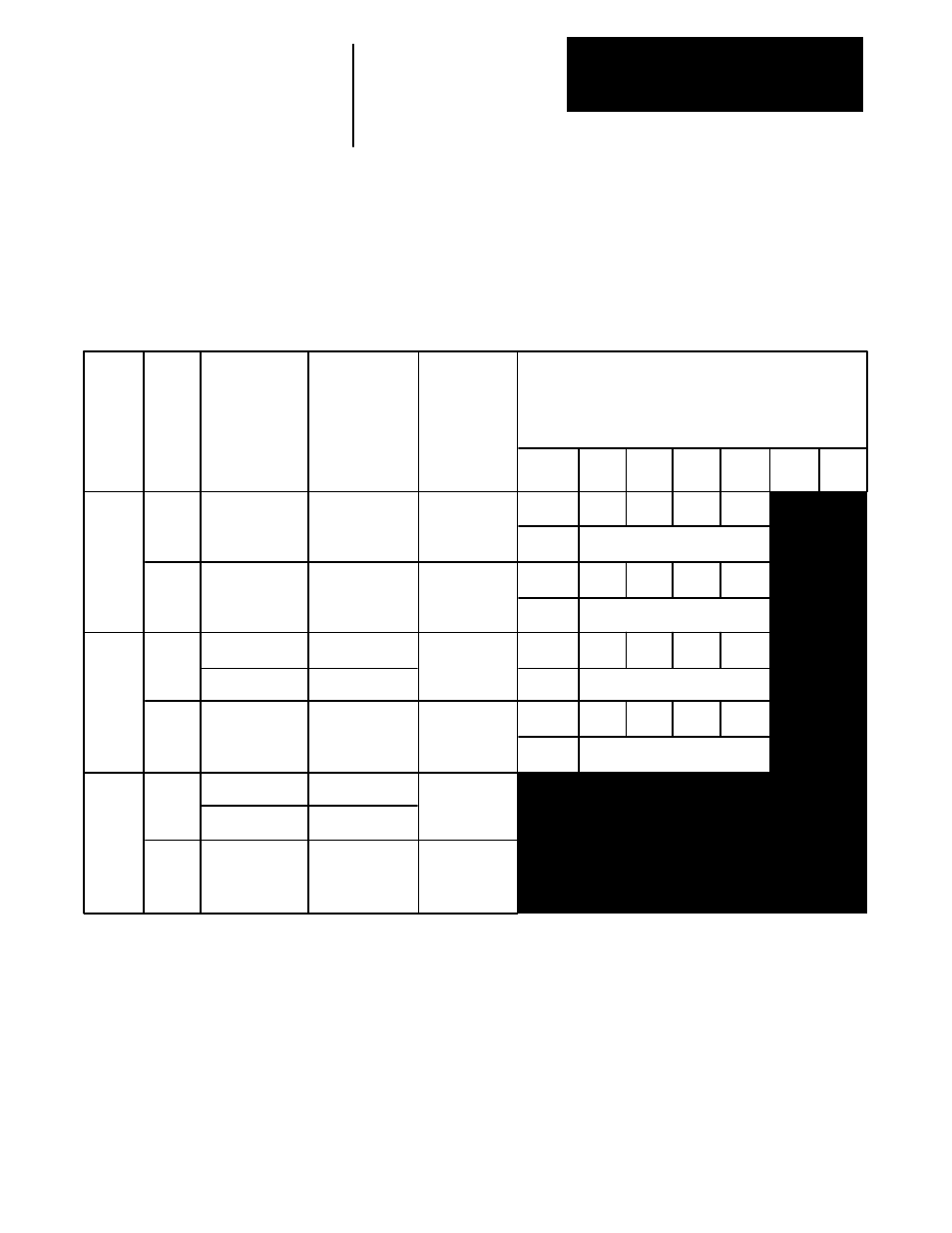

Wire Group Numbers

The following chart identifies general wire categories that will be

encountered when installing the 1336VT. Each category has an associated

wire group number that is used in the following sections to identify the

wire to be used. Application and signal examples along with the

recommended type of cable for each group is provided. A matrix providing

the recommended minimum spacing between different wire groups run in

the same tray or separate conduit is also provided.

Wire

Category

Wire

Group

Application

AC Power

(> 600 V AC)

AC Power

(to 600 V AC)

115VAC or 115V DC

Logic

24V AC or 24V DC

Logic

115V AC

Power

Analog Signals

DC Supplies

Digital

(Low Speed)

Digital

(High Speed)

Signal

Example

2.3 KV, 3

∅

AC Lines

480V, 3

∅

Relay Logic

PLC I/O

PLC I/O

Power Supplies

Instruments

5-24V DC

Supplies

Power Supplies

TTL Logic Level

Pulse Train

Input

Recommended

Cable

Per NEC

Local Codes

and

Application

Requirements

Belden 8760

Belden 8770

Belden 9460

Belden 8760

Belden 9460

Per NEC

Local Codes

and

Application

Requirements

Per NEC

Local Codes

and

Application

Requirements

Per NEC

Local Codes

and

Application

Requirements

9.00

(228.6)

3.00 (76.2)

Between Conduit

Between

Conduit

Between

Conduit

Between

Conduit

Between

Conduit

In

Tray

In

Tray

In

Tray

In

Tray

9.00

(228.6)

9.00

(228.6)

9.00

(228.6)

9.00

(228.6)

9.00

(228.6)

6.00

(152.4)

6.00

(152.4)

9.00

(228.6)

6.00

(152.4)

9.00

(228.6)

6.00

(152.4)

9.00

(228.6)

6.00

(152.4)

6.00

(152.4)

9.00

(228.6)

3.00 (76.2)

Between Conduit

3.00 (76.2)

Between Conduit

3.00 (76.2)

Between Conduit

For Tray:

Recommended minimum spacing between different wire

groups in the same tray

For Conduit:

Different wire groups must be run in separate conduit

All Dimensions in Inches and (Millimeters)

Wire

Group

Power

1

Power

2

Control

3

Control

4

Signal

5

Signal

6

Power

Signal

Control

1

2

3

4

5

6

All signal wiring must be run in separate steel conduit.

A wire tray is not suitable.

The minimum spacing between conduit containing

different wire groups is 3.00 inches (78.2 mm).

❶

❶

Refer to precautions in General Wiring Procedures concerning multi-conductor cables.

Belden 8760 — 18 AWG, twisted pair, shielded.

Belden 8770 — 18 AWG, 3 conductor, shielded.

Belden 9460 — 18 AWG, twisted pair, shielded.

Note 1 Steel conduit is recommended for all 1336VT power or control wiring and required for all 1336VT signal wiring. All input and output power wiring,

control wiring or conduit should be brought through the drive conduit entry holes provided. Use appropriate connectors to maintain the

environmental rating of the enclosure.

Note 2 Spacing between wire groups is the recommended minimum for parallel runs of 200 feet or less.

Note 3 All shields for shielded cable must be grounded at the drive end only –– Terminal 3 or 4 of TB2 –– The other end must be insulated and remain

floating. Shields for cables from one enclosure to another must be grounded only at the enclosure nearest the drive. If splicing of shielded cables is

required, the shield must remain continuous and insulated from ground.

Note 4 AC and DC circuits must be run in separate conduit or trays.

Note 5 A voltage drop in motor leads may adversely affect motor starting and running performance. Installation and application requirements may dictate

that larger wire sizes than indicated in the NEC guidelines be used.