Cv t – Steriflow JSRLP Series User Manual

Page 3

-3-

JSRLP S

eRieS

H

igH

P

uRity

B

io

-P

HaRma

g

aS

L

ow

P

ReSSuRe

R

educing

V

aLVe

F

eatures

& B

eneFits

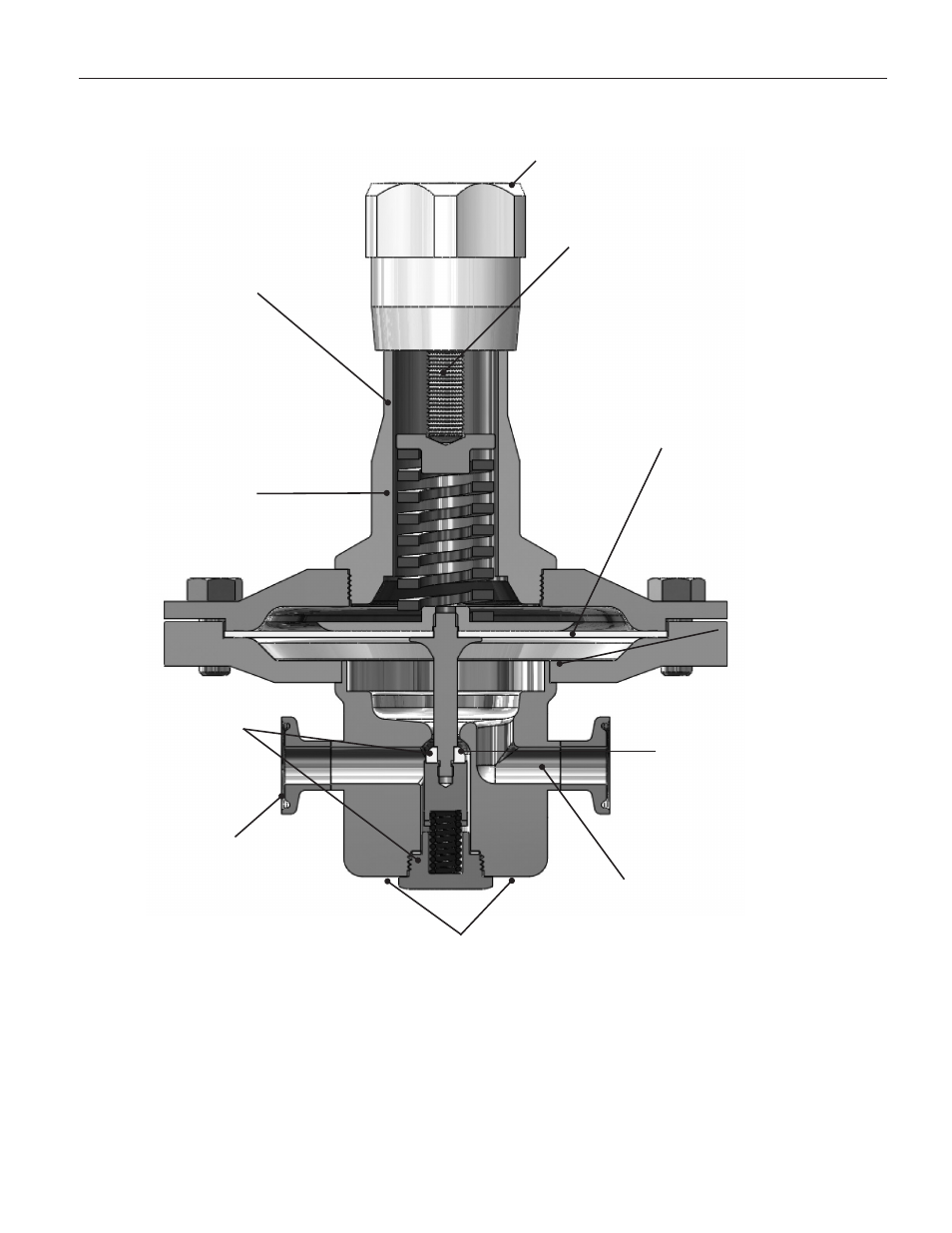

SST spring chamber

suitable for washdown

Panel mount and

captured vent -

options available

FDA/USP Class VI

seat and seal and

material for ANSI

Class VI shutoff

Sanitary clamp,

extended tube weld,

or FNPT connections

available

Bottom mounting

(optional)

EPDM seat material

available for extremely

low lockup

Large Teflon diaphragm FDA/

USP Class VI approved - for

accurate low pressure control

down to 1 psi

Fine thread pitch for

precision setpoint

adjustments

ASME BPE SF5, 20 Ra µin

(0.5 Ra µm) electropolish -

finish - standard on internal

surfaces and wetted parts

Reliable, gas pressure

regulation with set points to

1 psig (69 millibar)

Optional:

• Autoclavable annodized aluminum handle

• Handle lockout device

cV t

rim

s

election

i

nstructions

1. Select a graph on the next four pages that best represents your outlet pressure set point and flow range.

2. Select the inlet pressure line on the graph (horizontal sloped line, P1) that reflects your valve's actual

inlet pressure.

3. That line indicates the Pressure/Flow capabilities of the Cv trim under flowing conditions.