Steriflow JSRLP Series User Manual

Page 10

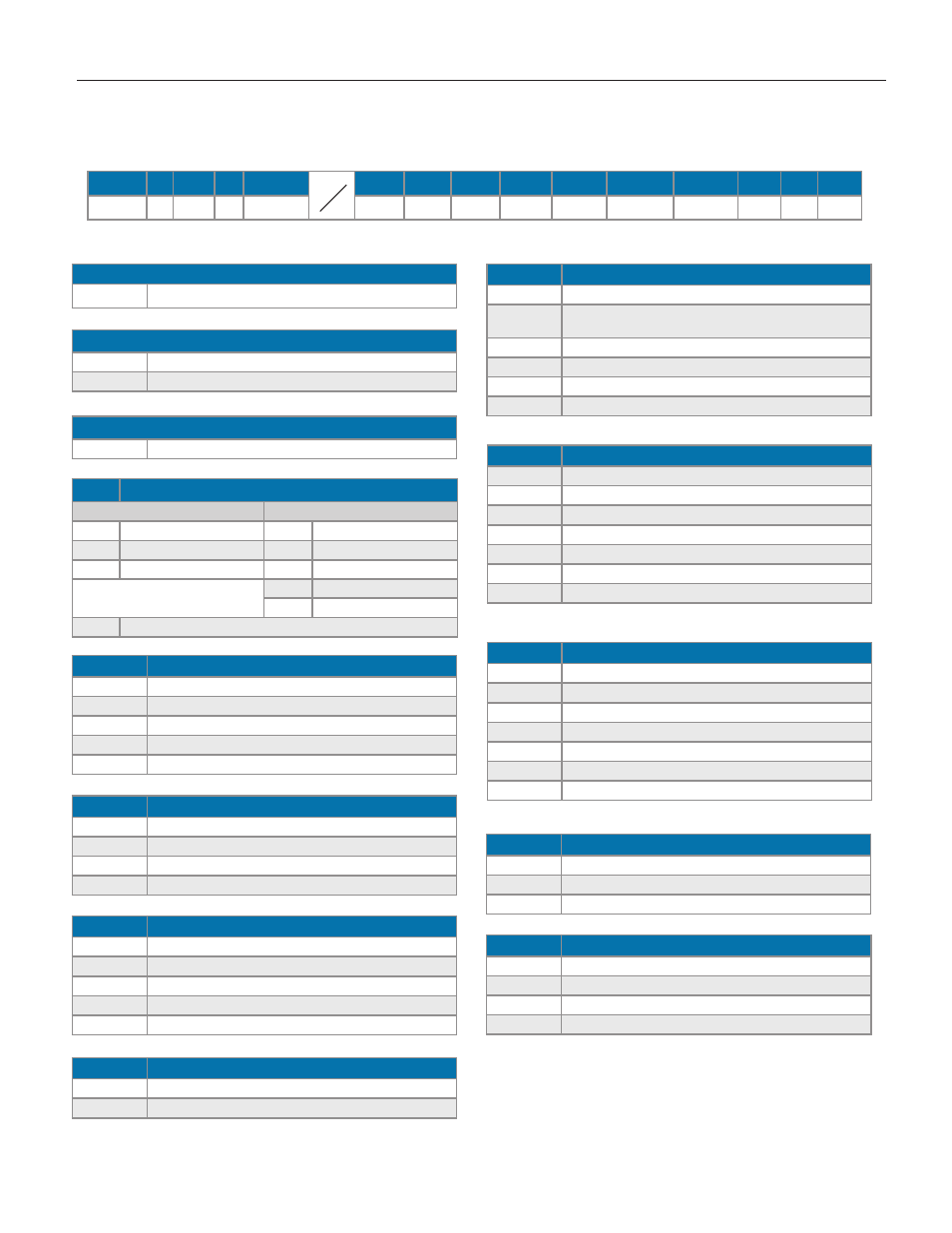

Model

Size

Material

1 & 2 3 & 4 5 & 6 7 & 8 9 & 10 11 & 12 13 & 14 15

16

17

JSRLP — 050 —

6L

Model

JSRLP

High Purity Gas Pressure Reducing Valve

Size

050

1/2"

075

3/4"

Material

6L

Stainless Steel 316L

1 & 2

Body Feature

End Connection

Port Configuration

C

Tri-Clamp 20 Ra EP

A

Port "A"

P

FNPT 20 Ra EP

B

Port "B"

T

BWE 20 Ra EP

C

Port "C"

D

Port "D"

E

Port "E"

ZZ Non-Standard

JSRLP S

eRieS

H

igH

P

uRity

B

io

-P

HaRma

g

aS

L

ow

P

ReSSuRe

R

educing

V

aLVe

o

rDering

s

chematic

3 & 4

Trim

1S

0.8 Cv

2S

0.5 Cv

1R

CV 0.8 Self-Relieving

2R

Cv 0.5 Self-Relieving

ZZ

Non-Standard

5 & 6

Seat Material

TF

PTFE

PK

Peek

EP

EPDM

ZZ

Non-Standard

7 & 8

Range Spring/Outlet Pressure

01

1 - 5 psi

05

5- 15 psi

15

15 - 25 psi

25

25 - 50 psi

ZZ

Non-Standard

9 & 10

Diaphragm Material

JL

Jorlon

ZZ

Non-Standard

11 & 12

Actuator

SK

Standard Actuator

AK

Standard Actuator / Autoclavable

Anod. Aluminum knob

PM

Panel Mount

CV

Captured Vent

TP

Tamper Proof

ZZ

Non-Standard

13 & 14

Inlet Gauge*

Ø

B

0 - 30 PSIG/Bar (Dual)

Ø

C

0 - 60 PSIG/Bar (Dual)

Ø

D

0 - 100 PSIG/Bar (Dual)

Ø

E

0 - 160 PSIG/Bar (Dual)

Ø

F

0 - 200 PSIG/Bar (Dual)

Ø

N

None

ZZ

Non-Standard

15

Outlet Gauge*

A

0-15 PSIG/Bar (Dual)

B

0 - 30 PSIG/Bar (Dual)

C

0 - 60 PSIG/Bar (Dual)

D

0 - 100 PSIG/Bar (Dual)

E

0-160 PSIG/Bar (Dual)

N

None

ZZ

Non-Standard

16

SEP Compliance

0

None Required

G

SEP Compliant

Z

Non-Standard

17

Accessories

0

None Required

S

Clean For Oil Free*

X

Clean for Oxygen*

Z

Non-Standard

* Gauges are Oil Free and O2 clean as standard.

* Gauges are Oil Free and O2 clean as standard.

-10-