3 terminology used, Terminology used, Communication manual 8400 motec profinet – Lenze E84DGFCR User Manual

Page 9

EDS84DMOTPNET EN 2.0 - 11/2011

L

9

Communication manual 8400 motec PROFINET

About this documentation

Terminology used

1.3

Terminology used

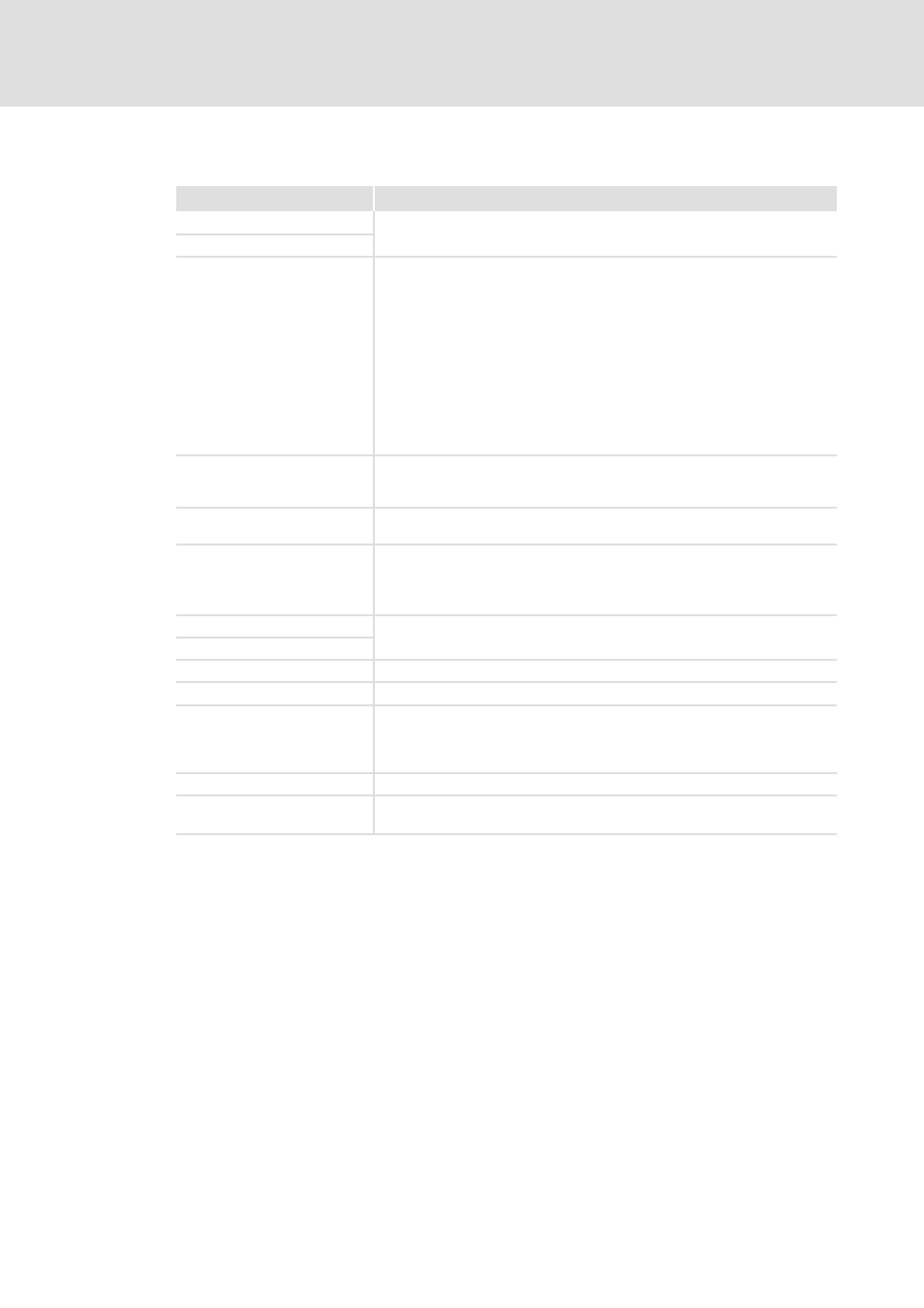

Term

Meaning

Controller

Lenze frequency inverter of the "Inverter Drives 8400 motec" product series

Standard device

Drive Unit

Communication Unit

Wiring Unit

The controller 8400 motec consists of the following modules: "Drive Unit",

"Communication Unit" and "Wiring Unit".

• The Drive Unit is available in various power classes.

• The Communication Unit is available in the following versions:

–No fieldbus

–AS-i option

–CANopen option

–PROFIBUS option

–PROFINET option

–EtherCAT option

• The Wiring Unit provides flexible connection options for an easy integration

into the power supply of the machine.

»Engineer«

PC software from Lenze which supports you in "engineering" (parameter setting,

diagnosing, and configuring) during the entire life cycle, i.e. from planning to

maintenance of the commissioned machine.

Code

Parameter which serves to parameterise and monitor the controller. In normal

usage, the term is usually referred to as "Index".

Subcode

If a code contains several parameters they are stored in so-called "subcodes".

In the documentation the forward slash "/" is used as a separator between the

designation of the code and the subcode (e.g. "C00118/3").

In normal usage, the term is also referred to as "Subindex".

Lenze setting

These are settings with which the device is preconfigured ex works.

Basic setting

HW

Hardware

SW

Software

I/O controller

PROFINET master

The I/O controller takes over the master function for data communication of the

decentralised field devices. The I/O controller usually is the communication

interface of a PLC.

I/O device

PROFINET slave

IO supervisor

Engineering and diagnostics tools

The IO supervisor can access process data, diagnostic data, and alarm data.