2 dgsl-…-n without cushioning components, 3 installation, pneumatic, 4 installation, electric – Festo DGSL User Manual

Page 6

• Screw in two screws for attaching the effective

load:

– into the yoke plate or

– into the slide.

Fig. 5

Installation of the DGSL:

• Use centring sleeves (

Accessories at www.festo.com/catalogue).

• Check whether adapter plates from the Festo multi-axis modular system are

required.

• Fasten the DGSL with the stated minimum number of screws: (

table Fig. 6).

If the slide is pushed into the retracted end position, the through-holes become

accessible.

Stroke

< 50 mm

Stroke

› 50 mm

Base-surface mount-

ing with:

– Threaded holes

– Through-holes

Minimum number of

screws

two

three

Fig. 6

Position sensing of the slide end

positions:

• Place the proximity switches in the

grooves

9.

On the DGSL-4, only SM

T-10

proximity switches are permitted.

• With the DGSL-4/-8, preferably use

the lower groove on the base side.

Fig. 7

9

Rough setting of the end positions:

Note

The DGSL may be damaged if the

slide is moved without a fixed stop.

• Make sure that the slide always re-

mains in the retracted end position

when the fixed stop is dismantled.

Fig. 8

1. Move the slide into the retracted end position.

2. Unscrew the mounting screws of the fixed stop and the required cover

aD

(

Fig. 10).

A reduction of a max. 2 standard strokes is possible (for DGSL-…-E the standard

stoke range cannot be completely covered).

Stroke

0

10

20

30

40

50

80

100

150

200

Stroke reduc-

tion

1)

Fig. 9

1)

Not for DGSL-…-E

3. Replace the fixed stop

6 with the cover aD.

4. Screw the fastening screws in again. The tightening

torque is summarised in the following table

(

Fig. 11).

Fig. 10

aD

6

DGSL

4

6

8

10

12

16

20

25

Tightening torque

[Nm]

0.76

1.3

1.3

2.9

2.9

6

9

9

Fig. 11

5. Complete the precision adjustment of the end positions on the cushioning com-

ponents (

6 Commissioning).

5.2 DGSL-…-N without cushioning components

Note

Operating the DGSL-…-N without shock absorbers will destroy the DGSL.

• Make sure that the DGSL is operated only with cushioning.

Cushioning components for retrofitting cushioning can be ordered separately and

installed in the DGSL subsequently (

10 Accessories).

Note

• Make sure that the following specifications are complied with:

– Max. permissible stop force (

12 Technical data),

– Use of safeguards (e.g. cover cap

10 Accessories).

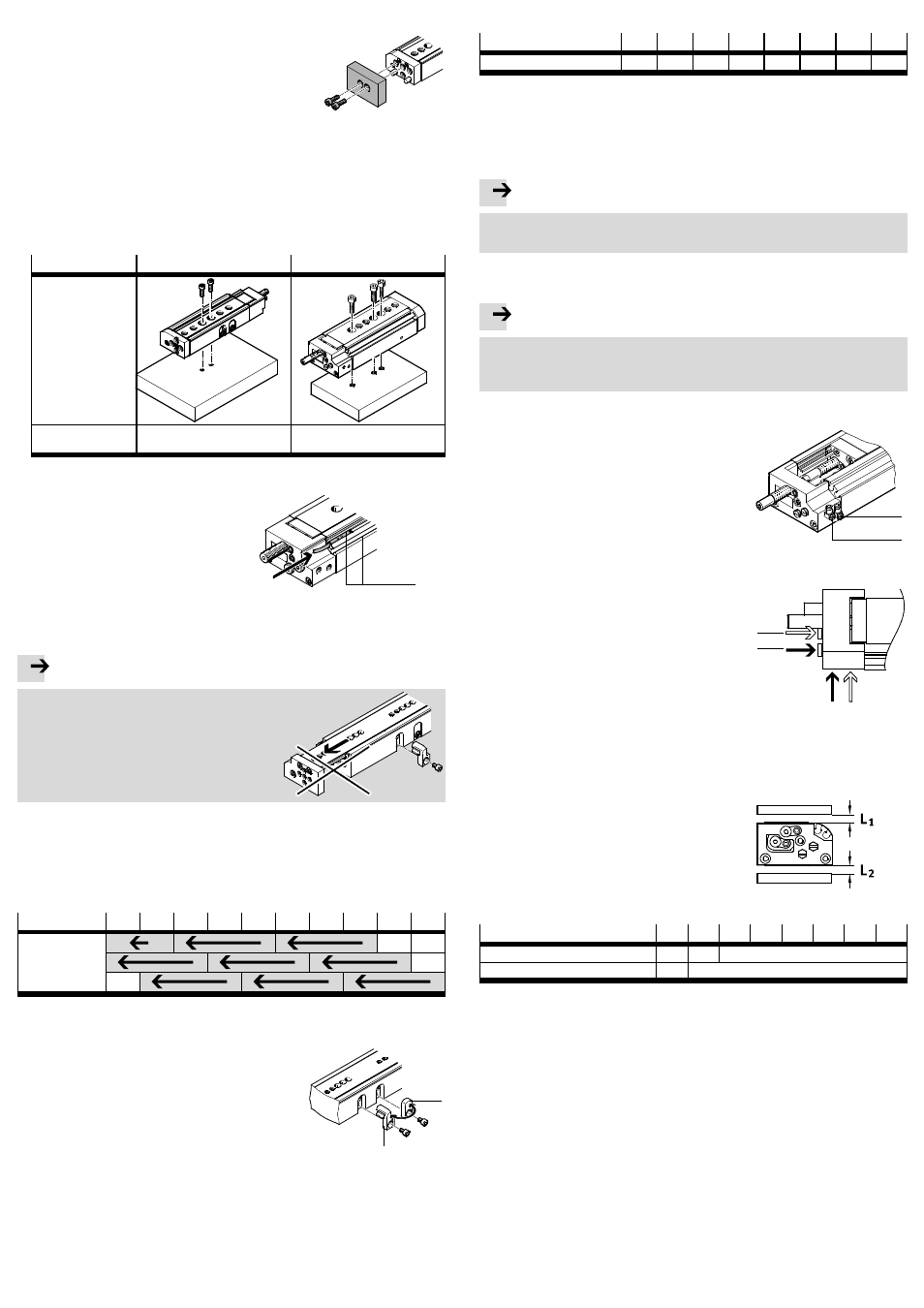

5.3 Installation, pneumatic

• Use one-way flow control valves for setting the

speed of the slide.

These are screwed directly into the compressed

air supply ports.

With size DGSL-4/-6, L-shaped restrictors on the

front of the supply port enable unhindered ac-

cess for cushioning setting (

Accessories at

www.festo.com/catalogue).

Fig. 12

aA

aJ

• Remove the transport covers on the compressed

air supply ports.

• Connect the tubing to the compressed air supply

ports:

–

aJ retracting

–

aA advancing

The connecting threads must be sealed. The al-

ternative connections

aB and aC to the com-

pressed air supply ports intended at the factory

are prefabricated for the DGSL. They are sealed

with blanking plugs.

Fig. 13

aA

aB

aJ

aC

5.4 Installation, electric

For position sensing with proximity switches:

• Observe the minimum distances L

1

and L

2

between static or moving ferritic masses and the

proximity sensors (

Fig. 14).

In this way you will avoid maloperation as a

result of external influences.

Fig. 14

DGSL

4

6

8

10

12

16

20

25

L1 to ferritic materials

[mm]

5

5

0

L2 to ferritic materials

15

0

Fig. 15