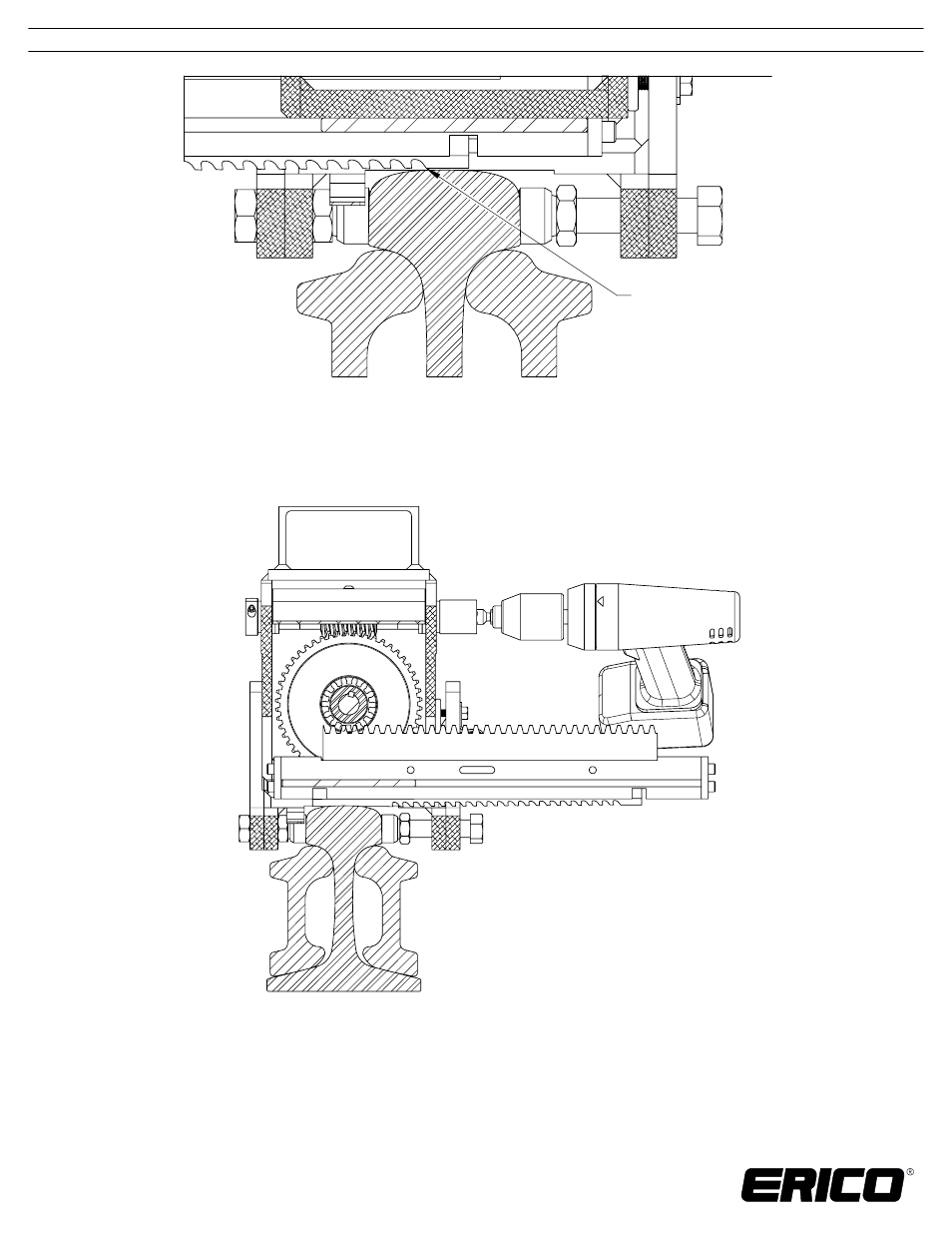

Sheet10, Section view c-c, Section view d-d – ERICO IJS100 Insulated Joint Slotter User Manual

Page 10

Cutting tool resting

on the rail

9. Turn the worm drive shaft counter-clockwise to move the cutting tool from the gauge side of the rail to

the field side. The gear rack should continue to the end of cut position (Figure 24). Care should

be taken that the rack gently reaches its end of travel position, as the drill will twist abruptly.

Figure 23: Cutting tool ready to cut

10. Repeat Steps 6 through 9 until the insulated joint is adequately cleaned.

11. To check the depth and the quality of the cut, the operator can remove the gearbox by

performing Step 2. Perform Step 5 to install the gearbox back into the base. Proceed

to follow Steps 6 through 9.

12. Once completed, loosen the adjustable clamping pads with a 15/16” hex socket and lift

the device off of the rail.

Figure 24: Position of the gear rack at the end of cut

TECHNICAL SUPPORT:

www.erico.com

IP8240_B

INSTRUCTION SHEET

10 OF 10

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

© 2012 ERICO International Corporation.

- 6Z34VF14 Rod Hanging Basket Tray Clip (1 page)

- 766PM Far Side Box Support (1 page)

- 766PMD Far Side Box Support (1 page)

- CADDY MPVTI Low Voltage Mounting Clip (2 pages)

- H-Series CADDY PYRAMID Support System (3 pages)

- CADDY PYRAMID RL, PIPE RETAINERS (2 pages)

- CADDY PYRAMID Rooftop Equipment Support (4 pages)

- CADDY PYRAMID Single Post Support (1 page)

- CADDY PYRAMID TF Series, Fixed Height Tool-Free Supports (2 pages)

- CADDY ROD LOCK Anchor Screw (2 pages)

- CADDY ROD LOCK Beam Clamp (2 pages)

- CADDY ROD LOCK Channel Nut (2 pages)

- CADDY ROD LOCK L-Bracket (2 pages)

- CADDY ROD LOCK Strut (2 pages)

- CADDY SPEED LINK Riveted Accessories (4 pages)

- CADDY SPEED LINK SLK-Keyless Locking Device and Bulk Cable (2 pages)

- CADDY SPEED LINK SLK-Keyless Locking Devices (2 pages)

- CADDY SPEED LINK-Accessory Cables (1 page)

- CADDY SPEED LINK-SLK Cable End Accessories (4 pages)

- TSGB Series Screw Gun Bracket (2 pages)

- GLIDER Electrical Box Attachment (2 pages)

- H Series-Electrical Box Bracket (2 pages)

- ROD LOCK Plywood Pre-set Anchor (2 pages)

- ROD LOCK Strut End Bracket (2 pages)

- ROD LOCK Strut (2 pages)

- CADDY ROD LOCK Strut Nut (2 pages)

- CER4 Cable from Stud (2 pages)

- High Performance CADDY CAT HP J-Hook Assemblies (6 pages)

- KBT Wire Basket Tray Clip (1 page)

- MPCB1220 (2 pages)

- SBC Series, Beam Clamp, 3/8" and M10 (1 page)

- TSR200 Telescoping Strut Replacement Bracket (2 pages)

- TSRBS1625 Telescoping Box (3 pages)

- Universal Pedestal Clamp (2 pages)

- Branch Line Restraint Device (2 pages)

- Branch Line Restraint Strucural Attachment Fitting for Steel 12 gauge (2 pages)

- Branch Line Restraint, Structural Attachment Fitting for Concrete or Wood (2 pages)

- Branch Line Restraint, Structural Attachment Fitting with 3/8"-16 male thread" (2 pages)

- 510 CADDY EZ RISER (2 pages)

- 429 CADDY MACROFIX PLUS NI (1 page)

- Seismic Hanger Clamps (3 pages)

- CADDY PYRAMID Equipment Supports (3 pages)

- CADDY ROD LOCK Bottom-Mount Duct Bracket (2 pages)

- Bottom-Mount Duct Bracket, Narrow (2 pages)

- Top-Mount Duct Bracket (2 pages)