Troubleshooting, Device repair and return, Engineering specifications – Det-Tronics C7052J UV/IR Flame Detector used with R7494, R7495 Controller User Manual

Page 23

TROUBLESHOOTING

Table 4 is intended to serve as an aid in locating the

source of a system malfunction. The R7495B Controller is

not designed to be repaired by the customer in the field,

but should be returned to the factory in the event of a mal-

function. Refer to the “Maintenance” section of this man-

ual for information regarding servicing of the detector.

DEVICE REPAIR AND RETURN

Prior to returning devices or components, contact the

nearest local Detector Electronics office so that an RMI

(Return Material Identification) number can be

assigned. A written statement describing the malfunc-

tion must accompany the returned device or component

to expedite finding the cause of the failure, thereby

reducing the time and cost of the repair to the customer.

Return all equipment transportation prepaid to the facto-

ry in Minneapolis.

Detector Electronics Corporation

6901 West 110th Street

Minneapolis, Minnesota 55438 USA

Operator: (952) 941-5665 or (800) 765-FIRE

Customer Service: (952) 946-6491

Fax: (952) 829-8750

Web site: www.detronics.com

E-mail: [email protected]

ENGINEERING SPECIFICATIONS

The UV/IR flame detection system shall have a micro-

processor-based controller that can operate up to 8

detectors and provide relay outputs through the use of a

relay output module. The controller shall be field pro-

grammable for selecting time delay length, sensitivity,

voting output configuration, and latching or non-latching

operation. The system shall operate on 24 vdc. The

UV/IR flame detection system shall be capable of

responding to a 1 foot by 1 foot gasoline fire at a dis-

tance of 50 feet. The detector shall be capable of 1.0

second response time to an intense fire signal. It shall

not respond to radiation generated by arc welding, x

rays, or hot surfaces, but shall be capable of respond-

ing to a fire in their presence. The UV/IR flame detector

shall be in a red, copper-free aluminum enclosure1.

The detector shall be the Det-Tronics model C7052J, no

equal. The controller shall be the Det-Tronics model

R7495B Controller and the that fits in the Det-Tronics

model Q4004 Mounting Rack which is designed to fit

standard 19” racks, no equal.

The UV/IR flame detector shall have one 3/4” NPT

2

entry

for field wiring.

The controller shall have visual annunciation of fire and

fault conditions. The controller shall have eight red

LEDs for individual detector alarm indications, one

green LED for power indication, one yellow LED for fault

indication, one red LED to indicate an alarm, and two

red LEDs for fire zone (voting) output indication.

The signal processing shall require the UV radiation and

the flickering IR radiation to exceed field adjust thresh-

old levels and time delay before signalling an alarm

condition. The detector shall have a 80 degree cone of

vision and be of a modular plug-in design that allows

the UV and IR sensor modules to be easily field

replaced without the use of special tools. All optical

surfaces shall be easy to access for cleaning. No metal

rods shall be allowed in front of the sensor windows.

The UV/IR flame detector shall have optical testing

capabilities on both the UV and IR sensor. Films that

blind the UV sensor or the IR sensor shall cause a fail-

ure of the optical test.

The UV/IR flame detector shall be rated for an operating

temperature range of -40°F to +167°F (–40°C to +75°C)

and a storage temperature of -40°F to +185°F (–40°C to

+85°C). The detector shall operate over a humidity

range of 0 to 95% RH and be able to withstand 100%

condensing humidity for short periods of time. All print-

ed circuit boards shall be coated to provide protection

from the environmental conditions. The UV/IR flame

detector shall meet MIL-STD 810C for vibration and

23

95-8302

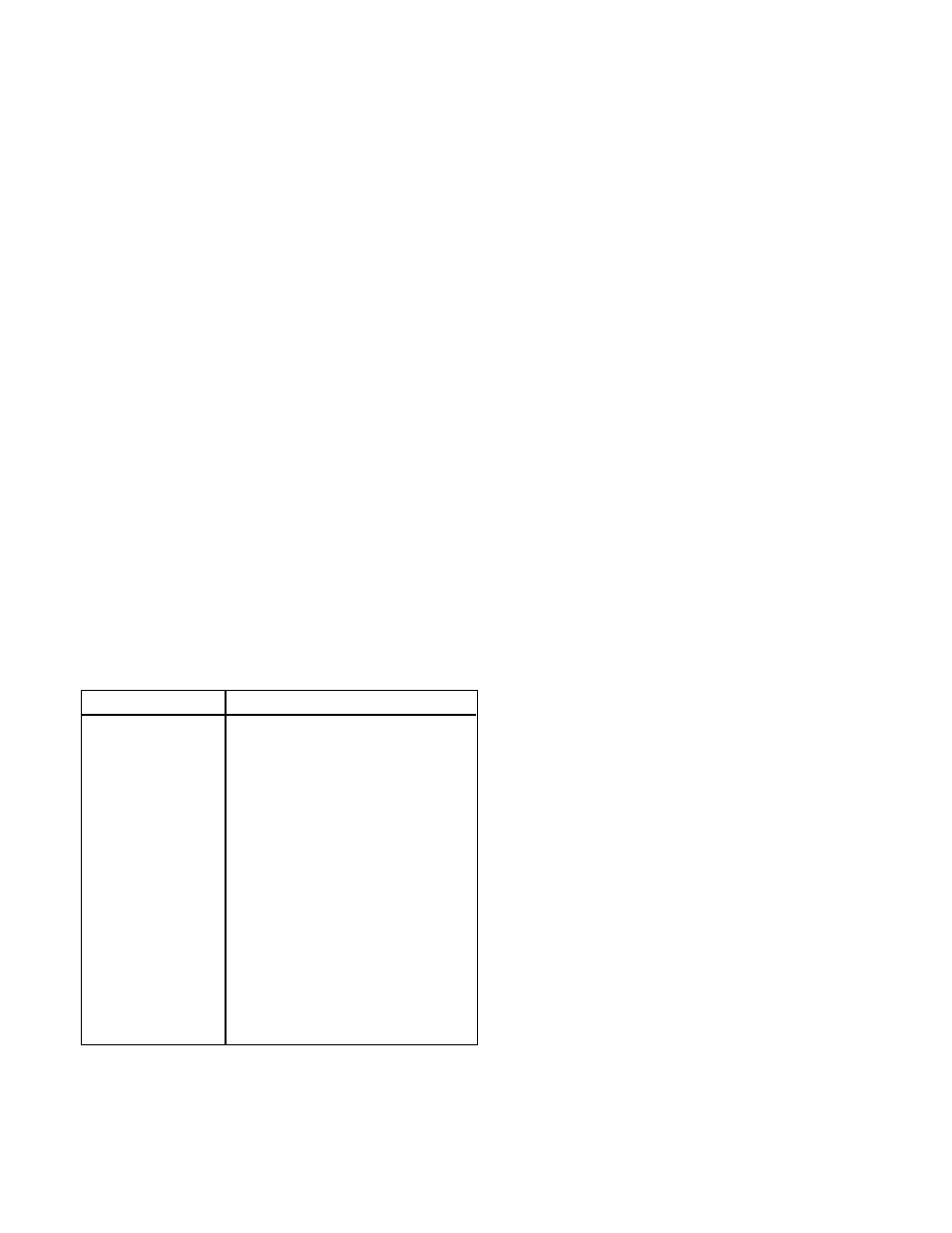

Table 4—Troubleshooting Guide

Problem

Possible Cause

No POWER LED

1. Input power failure.

2. Wiring to external power source

3. Controller power supply failure.

FAULT LED on

1. Mode switch in TEST position.

2. Low input voltage.

FAULT LED and a

1. oi fault - dirty window and/or the

DETECTOR LED on

oi ring

2. Detector module has lost sensitivity

3. Detector wiring problem

FAULT LED off,

1. Detector responding to UV/IR

DETECTOR LED

source not large enough to exceed

blinking slowly

the fire threshold programmed into

the controller

ALARM LED on, no

1. Mode switch in TEST position.

actuation of outputs

2. Output circuit failure.